Does Jb Weld Work on Stainless Steel? Expert Tips

Understanding JB Weld

JB Weld Overview

JB Weld is a widely recognized two-part epoxy adhesive known for its strength and durability. It consists of a resin and a hardener that, when mixed together, form a powerful bond capable of adhering to a variety of surfaces. The adhesive is formulated to withstand high temperatures, making it suitable for both household and industrial applications. For more details on how JB Weld compares to other adhesives, visit our comparison of jb weld vs. gorilla glue.

| Feature | Description |

|---|---|

| Composition | Two-part epoxy (resin and hardener) |

| Setting Time | 4-6 hours |

| Cure Time | 15-24 hours |

| Temperature Resistance | Up to 550°F (288°C) |

| Applications | Metal, wood, plastic, ceramic, and more |

Application on Different Materials

Stainless Steel:

JB Weld works effectively on stainless steel, providing a strong and lasting bond. According to user “nyengineer”, JB Weld can handle the temperatures found in engine environments, making it ideal for various automotive and industrial repairs (Bob Is The Oil Guy Forum). For specific uses and preparation tips, check the section on does jb weld work on stainless steel.

Aluminum:

JB Weld also excels at bonding aluminum surfaces, forming a reliable solution for repairing and bonding aluminum components. It is effective for filling gaps, seams, and cracks in items such as aluminum cookware, auto parts, and siding (Stickyn). For more details, visit does jb weld work on aluminum.

| Material | Effectiveness | Notable Applications |

|---|---|---|

| Stainless Steel | High | Automotive parts, kitchen appliances |

| Aluminum | High | Cookware, auto parts, siding |

| Plastic | Moderate | Household items, light fixtures |

| Wood | Moderate-High | Furniture repairs, wooden decor |

| Ceramic | High | Pottery, decorative items, tile repair |

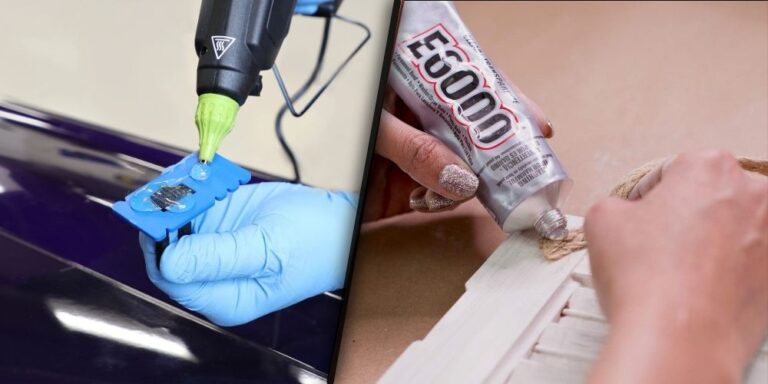

For more information on applying JB Weld to different materials, you can explore our articles on does jb weld work on brass, does jb weld work on copper, and does jb weld work on glass. Additionally, for other adhesive comparisons, check out e6000 vs. gorilla glue and flex seal vs. epoxy.

JB Weld Performance

When considering JB Weld for various applications, it’s essential to understand its performance characteristics, especially its strength, temperature resistance, and resistance to chemicals and water.

Strength and Durability

JB Weld is renowned for its strength and durability, making it an excellent adhesive for different materials, including stainless steel. When fully cured, JB Weld provides a strong bond with a tensile strength of up to 5020 PSI. This high tensile strength ensures that the bonded surfaces remain securely attached under considerable stress.

| Property | Value |

|---|---|

| Tensile Strength | Up to 5020 PSI |

| Durability | Permanent |

This exceptional strength is why JB Weld is commonly used in demanding applications such as automotive repairs, metal repairs, and construction. For more detailed comparisons, visit our JB Weld vs. Gorilla Glue page.

Temperature Resistance

One of the standout features of JB Weld is its impressive temperature resistance. After curing, JB Weld can withstand temperatures up to 550°F (288°C). This makes it particularly suitable for applications exposed to high temperatures, such as engine repairs or exhaust systems.

| Property | Value |

|---|---|

| Maximum Temperature | 550°F (288°C) |

For specific use cases, such as exhaust repairs, visit our guide on does JB Weld work on exhaust.

Chemical and Water Resistance

JB Weld also exhibits excellent resistance to chemicals and water, making it ideal for plumbing repairs and underwater applications. When cured, JB Weld resists common chemicals, solvents, and water, providing a reliable bond in harsh environments.

| Property | Performance |

|---|---|

| Chemical Resistance | Excellent |

| Water Resistance | Yes |

This resistance makes JB Weld an excellent choice for home repairs that might involve chemical exposure or contact with water. View our section on plumbing and home repairs for more information.

Whether used for metal, wood, or automotive repairs, JB Weld offers a dependable solution due to its strength, temperature tolerance, and chemical resistance. These qualities collectively validate its effectiveness as a versatile adhesive solution for various challenging environments. For more insights, read our article on how long does it take for JB Weld to dry.

Practical Applications of JB Weld

Automotive Repairs

J-B Weld products are popular in the automotive repair sector due to their versatility and strength. They can be used for a variety of repairs, from bumpers to exhaust systems (J-B Weld FAQs). The high heat resistance, up to -67ºF / -55ºC, makes them suitable for applications that endure significant temperature fluctuations.

| Automotive Application | Suitable J-B Weld Product |

|---|---|

| Bumper Repairs | J-B Weld Plastic Bonder |

| Exhaust Systems | J-B Weld ExtremeHeat |

| Radiator Repairs | J-B Weld RadiatorWeld |

| Engine Block Repair | J-B Weld Original Cold Weld Epoxy |

Check our other articles for more specific information on does jb weld work on exhaust and other automotive needs.

Plumbing and Home Repairs

JB Weld is also effective for various plumbing and home repairs. It can seal leaks, fix broken pipes, and even repair appliances. Its water-resistant and chemical-resistant properties are particularly useful in wet environments like kitchens and bathrooms.

| Plumbing Application | Suitable J-B Weld Product |

|---|---|

| Pipe Leaks | J-B Weld WaterWeld |

| Faucet Repairs | J-B Weld Original |

| Toilet Repairs | J-B Weld MarineWeld |

| Sink Fixes | J-B Weld ClearWeld |

For more comparisons and product specifics, see our articles on epoxy vs. super glue and rapid fuse vs. super glue.

Wood Restoration

Wood restoration tasks benefit greatly from the use of JB Weld products. They provide robust bonding for wooden surfaces and can fill gaps and cracks effectively. Products like J-B Weld KwikWood are designed specifically for wood repairs, offering excellent durability and ease of use.

| Wood Application | Suitable J-B Weld Product |

|---|---|

| Furniture Repair | J-B Weld KwikWood |

| Cabinet Repair | J-B Weld Wood Restore Premium |

| Floor Restoration | J-B Weld Original |

| Deck Repairs | J-B Weld Wood Restore Putty |

Explore more on wood-related adhesives in our articles on wood glue vs. white glue and how to remove super glue from legos.

By choosing the right JB Weld product for your specific needs, you can ensure efficient and lasting repairs across a variety of applications. Whether you’re dealing with automotive, plumbing, or wood restoration, JB Weld offers a solution that delivers dependable results.

Tips for Using JB Weld

Using JB Weld effectively requires careful attention to preparation, application, and cleanup. Here, we provide expert tips to ensure optimal performance when using JB Weld, particularly for those curious about does JB Weld work on stainless steel.

Surface Preparation

Proper surface preparation is crucial for the success of any JB Weld application. Here are the steps to follow:

- Clean and Dry: Ensure the surfaces are clean, dry, and free from grease or oil. Avoid using alcohol or cleaners that leave a petroleum residue.

- Abrade the Surface: For better adhesion, rough up the surfaces with sandpaper or an abrasive cloth. This helps the epoxy bond more effectively (J-B Weld FAQs).

Mixing and Application

Follow these steps for mixing and applying JB Weld:

- Mixing: Equally mix the two parts of the JB Weld epoxy. Ensure a thorough mix to achieve the best bond.

- Application: Apply the mixed epoxy to one of the prepped surfaces. Spread it evenly for a strong bond.

| Step | Description |

|---|---|

| 1 | Mix equal parts of the epoxy thoroughly |

| 2 | Apply a consistent layer to one surface |

| 3 | Press the surfaces together, ensuring alignment |

For more details on using different adhesives, see devcon vs. jb weld and marine tex vs. jb weld.

Removal and Cleanup

Proper cleanup is necessary to maintain the integrity of the bond and to ensure safety. Here’s how to do it:

- Before Curing: Wipe away excess epoxy with a cloth soaked in acetone or an acetone-based product. This is effective in removing JB Weld from hands and surfaces.

- After Curing: Fully cured JB Weld requires more aggressive methods. Options include grinding, filing, or heating above 600°F for removal (J-B Weld FAQs).

For additional resources on glue products and comparisons, check out belzona epoxy vs. jb weld epoxy or bondo vs. jb weld.

Understanding these tips and techniques ensures that you get the best results when using JB Weld. For more information on adhesives and how they compare, visit our articles on epoxy vs. super glue and zap a gap vs. super glue.

Common Questions about JB Weld

When considering whether J-B Weld works on stainless steel, there are several common questions that users often have. Here we address conductivity and insulation, food safety concerns, and the variety of J-B Weld products available.

Conductivity and Insulation

J-B Weld is known to be an insulator, not a conductor of electricity (J-B Weld FAQs). This means that J-B Weld will not conduct electricity and can safely be used in electrical applications where insulation is required.

| Property | J-B Weld |

|---|---|

| Conductive | No |

| Insulating | Yes |

Understanding these properties is crucial for anyone planning to use J-B Weld in electrical repairs or environments where electrical conductivity must be controlled.

Food Safety Concerns

A common question posed by users is whether J-B Weld is food safe. While J-B Weld provides unique bonding capabilities, it is essential to note that it is not marketed as a food-safe product. Thus, it is not recommended to use J-B Weld in applications that will be in direct contact with food.

For users seeking food-safe adhesives, it is advisable to explore other specialized products designed explicitly for food surfaces. For adhesive comparisons, consider reading our articles on epoxy vs. super glue or rubber cement vs. super glue.

Product Variety and Specifications

J-B Weld offers a wide range of products tailored for different repair needs. This variety includes solutions for automotive repairs, plumbing, wood restoration, and more (J-B Weld FAQs). It is important to select the appropriate type of J-B Weld for your specific project to ensure optimal performance.

| Product Type | Application | Features |

|---|---|---|

| Original J-B Weld | General repairs, metal bonding | Strong, permanent bond |

| J-B KwikWeld | Quick repairs | Fast setting time |

| J-B WaterWeld | Plumbing, underwater repairs | Water resistance |

| J-B HighHeat | High-temperature applications | Heat resistance |

| J-B WoodWeld | Wood repairs, restoration | Wood bonding properties |

| J-B PlasticWeld | Plastic repairs | Plastic bonding properties |

For more detailed comparisons between various glues and adhesives, consider visiting our articles on jb weld vs. gorilla glue and belzona epoxy vs. jb weld epoxy.

By understanding the properties and capabilities of J-B Weld, users can make informed decisions about their repair projects and ensure they choose the correct product for their specific needs. To further explore whether J-B Weld works on different materials, refer to our articles does jb weld work on brass and does jb weld work on exhaust.