Does Jb Weld Work on Glass? Surface Bond Guide

Understanding ClearWeld™ Epoxy

ClearWeld™ Epoxy is a versatile adhesive solution that provides strong and lasting bonds across a variety of surfaces, including glass. This section explores its application surfaces and tensile strength.

Application Surfaces for ClearWeld™

ClearWeld™ is a quick-setting, multipurpose two-part epoxy designed to provide a robust bond on a wide range of surfaces. Its versatility makes it suitable for bonding materials such as tile, ceramics, plastics, wood, metal, and glass (J-B Weld). This makes it an ideal choice for various repair and construction projects where a clear, transparent bond is desired.

| Surface Type | Suitability |

|---|---|

| Tile | High |

| Ceramics | High |

| Plastics | High |

| Wood | High |

| Metal | High |

| Glass | High |

For detailed use cases and application techniques, see our related articles on how to use e6000 glue on glass and how to remove super glue from legos.

Tensile Strength of ClearWeld™

ClearWeld™ boasts a tensile strength of 3900 PSI, meaning it can handle significant stress before breaking. This high tensile strength ensures that bonds created with ClearWeld™ are durable and long-lasting, even under demanding conditions (J-B Weld). Its clear, transparent bond is achieved when used at thicknesses of less than 15 mil, adding aesthetic value to reliable performance.

| Property | Value |

|---|---|

| Tensile Strength | 3900 PSI |

| Set Time | 5 minutes |

| Cure Time | 1 hour |

| Mixing Ratio | 1:1 |

Check out our comparison articles to see how ClearWeld™ measures up against other adhesives:

ClearWeld™ is an impressive option for those seeking a dependable and clear bonding agent. Whether for glass or other materials, its versatility and strength make it a go-to solution for various adhesive needs. For other bonding agents and comparisons, visit the articles on marine tex vs. jb weld and belzona epoxy vs. jb weld epoxy.

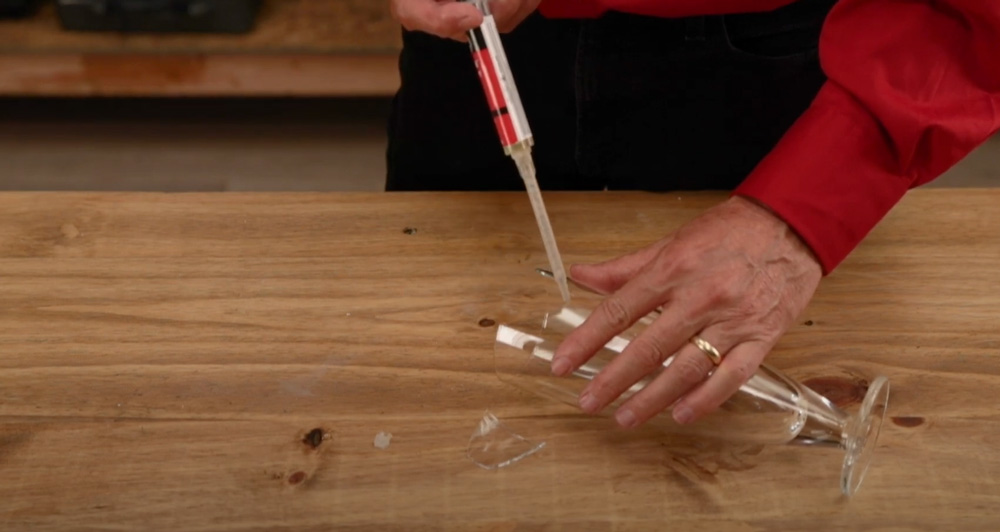

JB Weld on Glass

Suitability of JB Weld for Glass

JB Weld’s ClearWeld™ epoxy is particularly suited for bonding glass surfaces. This two-part epoxy provides a strong and durable bond on various materials, including tile, most plastics, ceramic, wood, metal, and specifically, glass (JB Weld). It is designed to cure with a clear, transparent bond when applied at a thickness of less than 15 mil. This makes ClearWeld™ ideal for applications where the appearance of the bond is crucial.

The mixing ratio for ClearWeld™ is 1:1, and it sets in approximately 5 minutes, with a full cure achieved within 1 hour (J-B Weld). Considering these properties, JB Weld stands out as an efficient option for those pondering the question, “does JB Weld work on glass?”

Tensile Strength on Glass

The tensile strength of JB Weld’s ClearWeld™ epoxy on glass is substantial, providing a robust bond. The tensile strength for this epoxy reaches up to 3900 PSI (JB Weld). This strong adhesion capability makes JB Weld a reliable choice for glass bonding applications.

| Property | Value |

|---|---|

| Setting Time | 5 minutes |

| Cure Time | 1 hour |

| Tensile Strength | 3900 PSI |

| Mixing Ratio | 1:1 |

| Bond Thickness | < 15 mil |

JB Weld’s efficacy on glass not only provides a strong bond but also ensures a neat finish due to its transparent curing property. This makes it a preferable option compared to other adhesives like Loctite PL Marine vs. 5200 or even rubber cement vs. super glue for glass applications.

For those wanting to explore comparisons with other bonding agents beyond JB Weld, they may find insights in discussions within the Rocketry Community or Beyond JB Weld.

Usage Recommendations

Precautions for Food Contact

J-B Weld is renowned for its strong bonding properties but it is crucial to consider its suitability for specific applications. When it comes to food contact, J-B Weld should be used with caution. Although J-B Weld is non-toxic once fully cured, it is not rated as food-safe. As a result, it is not advisable to use J-B Weld on surfaces that will directly touch food or beverages.

| Feature | Safe for Food Contact |

|---|---|

| Non-toxic when cured | Yes |

| Food-safe rating | No |

| Recommended for surfaces touching food | No |

For applications involving food, consider alternatives that are specifically designed and rated safe. For instance, the article on loctite pl marine vs. 5200 delves into adhesives with potential food contact considerations.

Conductivity of JB Weld

An important property to consider when using J-B Weld is its electrical conductivity. J-B Weld is an insulator and does not conduct electricity. This makes it suitable for applications where electrical insulation is required.

| Property | J-B Weld |

|---|---|

| Conducts electricity | No |

| Acts as an insulator | Yes |

Understanding these properties can help ensure J-B Weld is used appropriately based on the requirements of your project. For further discussions on adhesive comparisons, you might find the articles on epoxy vs. super glue and rapid fuse vs. super glue useful.

In summary, while J-B Weld is a versatile and strong adhesive, it’s essential to be aware of its limitations regarding food contact and electrical conductivity to make informed usage decisions. If you seek alternatives for specific requirements, browse our detailed guides and comparisons such as e6000 vs. gorilla glue and jb weld vs. gorilla glue.

Removing and Thinning JB Weld

When working with JB Weld, situations may arise where it’s necessary to remove or thin the product. Here are some effective methods to accomplish these tasks.

Methods for Removing JB Weld

Removing JB Weld from surfaces can be a meticulous process. Depending on whether the product is cured or uncured, different methods can be applied.

Uncured JB Weld:

- Acetone: Acetone or acetone-based products can be used to effectively remove uncured JB Weld from hands and surfaces (J-B Weld FAQs). Simply apply acetone to a cloth and wipe the area clean.

- Alcohol: Rubbing alcohol can also help in removing uncured JB Weld.

Cured JB Weld:

- Mechanical Removal: Once JB Weld has fully cured, it generally requires mechanical methods for removal. Light to moderate abrasive tools might be necessary (J-B Weld FAQs).

- Heat: Applying heat above the product’s 600ºF threshold can weaken the bond, allowing it to be scraped or sanded off more easily.

- Grinding or Filing: In cases where acetone or heat are ineffective, the cured JB Weld can be ground or filed off.

Thinning JB Weld

Thinning JB Weld can make it easier to apply in certain scenarios. Here are the recommended methods for achieving the desired consistency.

- Acetone: Adding acetone is a common way to thin JB Weld. You can add up to one teaspoon of acetone per two ounces (one full package) of mixed product (J-B Weld FAQs).

- Lacquer Thinner: Similarly, adding lacquer thinner can help in achieving a smoother, more spreadable consistency.

| Thinning Agent | Amount per 2 oz. of JB Weld |

|---|---|

| Acetone | Up to 1 teaspoon |

| Lacquer Thinner | Up to 1 teaspoon |

These methods ensure that you can work with JB Weld effectively and efficiently, whether you need to thin it for a smoother application or remove it when necessary. For more on adhesives, check out our articles on how to remove super glue from legos and rubber cement vs. super glue.

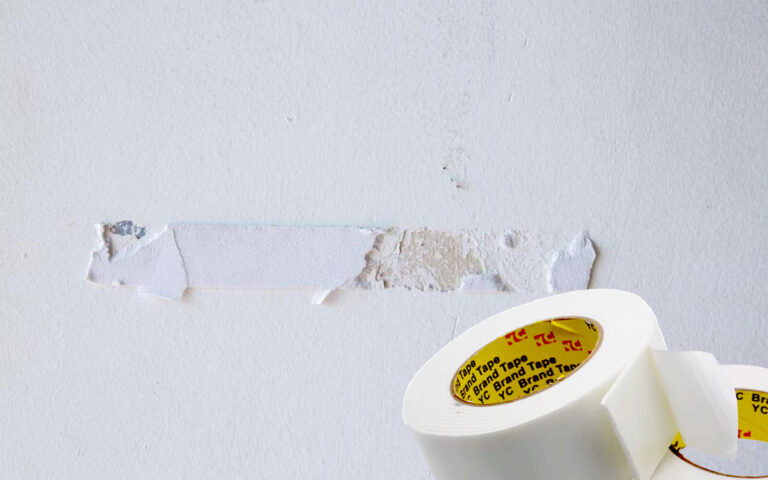

Surface Preparation for JB Weld

Proper preparation of surfaces is essential for achieving strong and durable bonds with JB Weld. This process involves both roughening and cleaning the surfaces to be bonded.

Roughening Surfaces

Roughening the surface increases the bonding area and provides a better grip for the adhesive. This can be done using light sandpaper or an abrasive cloth. Lightly sanding the area ensures that the adhesive can penetrate the small grooves and create a stronger bond.

- Use medium-grit sandpaper (around 80-120 grit).

- Gently sand the surface in a circular motion.

- Ensure the entire bonding area is evenly roughened.

Cleaning Surfaces

Cleaning the surfaces is crucial to remove any contaminants like grease, oil, or dust that could compromise the adhesive bond. The following cleaning methods are recommended:

- Acetone or Lacquer Thinner: Effective for removing oils and residues.

- Soap and Water: Suitable for general cleaning but ensure the surface is thoroughly dried afterward.

Here’s a step-by-step guide for cleaning:

- Apply acetone, lacquer thinner, or soapy water to a clean cloth.

- Wipe the surface thoroughly to remove any contaminants.

- Let the surface dry completely before applying JB Weld.

| Cleaning Method | Recommended For | Drying Time |

|---|---|---|

| Acetone | Removing oils and residues | Quick evaporation |

| Lacquer Thinner | Heavy-duty cleaning | Quick evaporation |

| Soap and Water | General cleaning | Ensure complete dryness |

Proper surface preparation not only enhances the bond strength but also ensures longevity and durability. For further insights on effective bonding agents beyond JB Weld, you can explore discussions in the Rocketry Community. If you are interested in a comparative analysis, you might find our article on jb weld vs. gorilla glue useful.

For those dealing with specific materials, other resources such as does jb weld work on plastic and does jb weld work on stainless steel are available.

Alternative Bonding Agents

Rocketry Community Discussions

In the rocketry community, there is frequent discussion about the best adhesive solutions for various components. While JB Weld is popular for its strong bonding capabilities, users of the Rocketry Forum have explored a range of alternatives that may be more suitable for specific applications. This indicates a need for effective bonding agents beyond JB Weld, especially when dealing with different materials or environmental conditions.

Beyond JB Weld

JB Weld is a versatile adhesive, but there are other high-performance alternatives available that may better suit certain needs. Here are a few notable options:

| Bonding Agent | Key Features | Applications |

|---|---|---|

| Loctite PL Marine vs. 5200 | Waterproof, flexible, excellent for marine use | Sealing, bonding in moist or submerged environments |

| E6000 vs. Gorilla Glue | Industrial strength, flexible, dries clear | Jewelry, glass, and craft projects |

| Epoxy vs. Super Glue | Long-lasting, heat-resistant, extremely strong | Metals, ceramics, and heavy-duty repairs |

| Rapid Fuse vs. Super Glue | Quick bond time, versatile, works on various surfaces | Household repairs, arts and crafts |

| Dap Rapid Fuse vs. Gorilla Glue | Fast-setting, durable bond, water-resistant | Woodworking, plastic, and general repairs |

For instance, E6000 adhesive is highly recommended for glass due to its clear drying and strong bond. On the other hand, Loctite PL Marine is preferred for marine-related applications because of its moisture resistance and flexibility. Exploring these alternatives can help find the best solution for specific bonding requirements, whether they relate to rocketry, glass repair, or other specialized uses.

Users can explore comparative analysis between different bonding agents like Bondo vs. JB Weld, Devcon vs. JB Weld, and Marine Tex vs. JB Weld. These comparisons highlight strengths and weaknesses tailored to various applications, helping individuals to make the most informed choice.

Understanding the full scope of alternatives to JB Weld can significantly benefit those looking for optimal adhesive solutions. Whether one is involved in rocketry, glass repairs, or any other specialized craft, knowing the right bonding agent is essential for success.