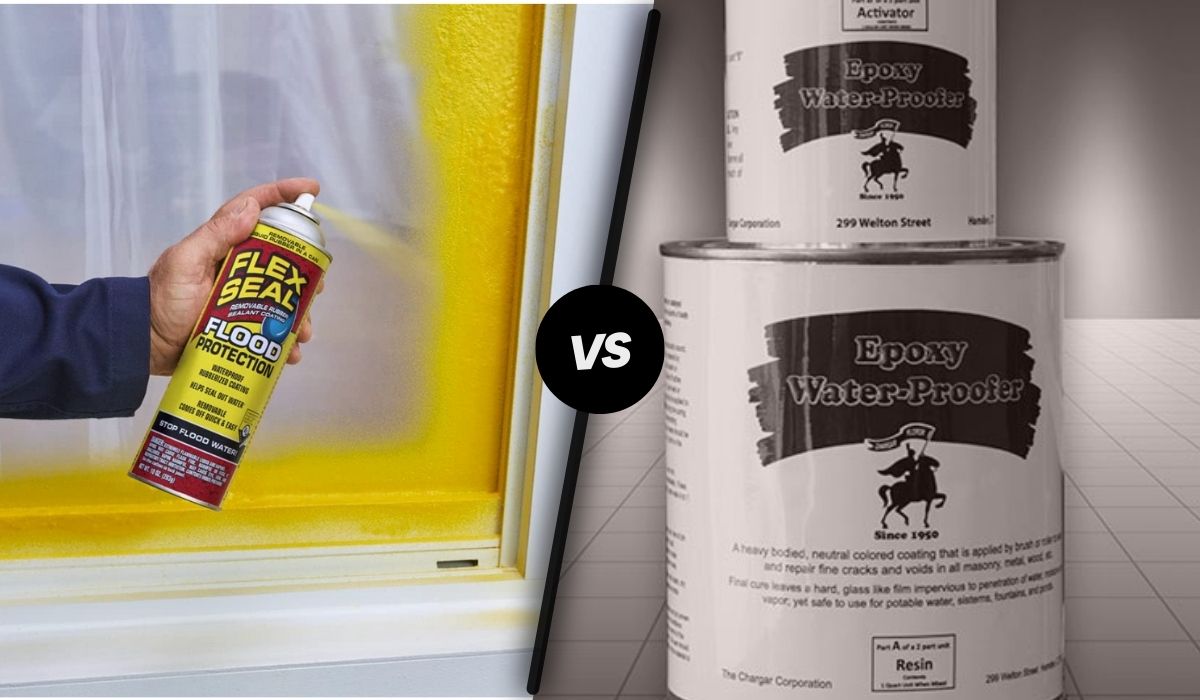

Flex Seal vs. Epoxy: Waterproof Seal Comparison

When it comes to waterproofing solutions, both Flex Seal and epoxy resin are popular choices. Each offers unique properties and advantages, making them suitable for different applications. This article provides an in-depth comparison between Flex Seal and epoxy, focusing on their waterproofing capabilities, durability, application methods, and more.

1. Overview of Flex Seal

Flex Seal is a liquid rubber sealant designed to seep into cracks and holes, creating a waterproof barrier upon drying. It is available in various forms, including spray cans, liquid form in paint buckets, and sealant tape, catering to different repair needs.

Key Features of Flex Seal:

- Material Composition: Rubber-based sealant.

- Drying Time: Typically dries within 2 to 3 hours.

- Curing Time: Fully cures in approximately 24 hours.

- Paintability: Can be painted over once fully cured.

- Color Options: Available in various colors to match different surfaces.

- Application Methods: Available in spray cans, liquid form, and tape.

2. Overview of Epoxy Resin

Epoxy resin is a two-component adhesive consisting of a resin and a hardener. When mixed, they undergo a chemical reaction, forming a rigid, durable, and waterproof bond. Epoxy is renowned for its high strength, chemical resistance, and ability to fill gaps and uneven surfaces.

Key Features of Epoxy Resin:

- Material Composition: Consists of epoxy polymer (resin) and a hardener.

- Drying Time: Initial set time can be as short as 6 minutes, depending on the formulation.

- Curing Time: Can take from 24 hours to several days to fully cure, depending on the specific product and environmental conditions.

- Paintability: Generally not paintable; paint may not adhere well to epoxy surfaces.

- Color Options: Typically clear or amber; colorants can be added during mixing.

- Application Methods: Requires mixing of resin and hardener; applied using tools like brushes or spatulas.

3. Waterproofing Capabilities

Both Flex Seal and epoxy resin offer waterproofing properties, but their effectiveness varies based on application and environmental conditions.

Flex Seal:

- Waterproofing: Creates a flexible, rubberized barrier that prevents water penetration.

- Applications: Suitable for sealing leaks in roofs, gutters, pipes, and other surfaces exposed to moisture.

- Limitations: May not withstand constant submersion or high-pressure water exposure over extended periods.

Epoxy Resin:

- Waterproofing: Forms a hard, impermeable surface that is highly resistant to water.

- Applications: Ideal for sealing and bonding materials in marine environments, such as boat repairs, and for waterproofing concrete floors.

- Limitations: Less flexible than rubber-based sealants; may crack under stress or movement.

4. Durability and Longevity

The longevity of a sealant is crucial, especially in environments exposed to harsh conditions.

Flex Seal:

- Durability: Offers a flexible rubber coating that provides a protective barrier against water, leaks, and corrosion.

- Longevity: Known for its ability to seal cracks and leaks effectively; resistant to water and weather damage.

- Maintenance: May require reapplication over time, especially in areas with extreme weather conditions.

Epoxy Resin:

- Durability: Provides superior resistance to chemicals and heat; creates a hard, protective coating over surfaces.

- Longevity: Known for its long-lasting durability and strength; can withstand heavy loads and harsh environments.

- Maintenance: Generally requires minimal maintenance once fully cured.

5. Application Methods and Ease of Use

The application process can significantly impact the effectiveness of the sealant.

Flex Seal:

- Application Process: Easy spray-on application; no specialized skills or equipment needed.

- Drying Time: Quick drying time; typically dries within 2 to 3 hours.

- Curing Time: Fully cures in approximately 24 hours.

- User-Friendliness: Suitable for quick fixes and smaller projects; ideal for beginners and DIY enthusiasts.

Epoxy Resin:

- Application Process: Requires mixing of resin and hardener; careful preparation and attention to detail needed.

- Drying Time: Initial set time can be as short as 6 minutes, depending on the formulation.

- Curing Time: Can take from 24 hours to several days to fully cure.

- User-Friendliness: More suitable for projects requiring a strong, lasting bond; may require more careful preparation and application.

6. Material Compatibility

The effectiveness of a sealant depends on its compatibility with the materials involved.

Flex Seal:

- Compatible Materials: Works on a wide range of materials, including metal, wood, plastic, concrete, glass, brick, ceramic, and more.

- Limitations: May not adhere well to certain plastics or surfaces with existing coatings; testing on a small area is recommended.

Epoxy Resin:

- Compatible Materials: Bonds effectively with metal, wood, glass, concrete, and some plastics.

- Limitations: Surface preparation is crucial; may not adhere well to oily or greasy surfaces.

7. Cost Considerations

Budget is often a determining factor in choosing a sealant.

Flex Seal:

- Cost: Generally more affordable; suitable for quick fixes and smaller projects.

- Value: Offers a cost-effective solution for minor repairs and sealing needs.

Epoxy Resin:

- Cost: Typically more expensive; suitable for projects requiring a strong, lasting bond.

- Value: Provides a durable and long-lasting solution; cost-effective in the long run for heavy-duty applications.

To assist in selecting the appropriate sealant for your specific needs, the following tables provide a detailed comparison between Flex Seal and epoxy resin across various parameters.

1. Comparative Overview

| Feature | Flex Seal | Epoxy Resin |

|---|---|---|

| Composition | Rubber-based liquid sealant | Two-component system: resin and hardener |

| Application Method | Spray, liquid, or tape | Mixing required; applied with brush, roller, or spatula |

| Drying Time | 2–3 hours | Initial set in 6 minutes; full cure in 24 hours to several days |

| Flexibility | High flexibility; accommodates movement | Rigid once cured; limited flexibility |

| Durability | Moderate; may require reapplication in harsh conditions | High; resistant to chemicals, heat, and heavy loads |

| Paintability | Paintable after curing | Generally not paintable; paint may not adhere well |

| Color Options | Multiple colors available | Typically clear or amber; colorants can be added during mixing |

| Cost | $12–$30 per can | $20–$50 per kit |

| Ideal Uses | Sealing leaks in roofs, gutters, pipes; quick fixes | Structural bonding, marine repairs, heavy-duty sealing |

2. Material Compatibility

| Material | Flex Seal Compatibility | Epoxy Resin Compatibility |

|---|---|---|

| Metal | Yes | Yes |

| Wood | Yes | Yes |

| Plastic | Yes (varies by type) | Yes (with proper surface preparation) |

| Concrete | Yes | Yes |

| Glass | Yes | Yes |

| Brick | Yes | Yes |

| Ceramic | Yes | Yes |

| Rubber | Yes | Yes |

3. Application Scenarios

| Application | Recommended Sealant | Reasoning |

|---|---|---|

| Roof Leak Repair | Flex Seal | Easy application; flexible to accommodate roof movements |

| Boat Hull Repair | Epoxy Resin | High strength and durability; excellent waterproofing for marine environments |

| Cracked Pipe Sealing | Flex Seal | Quick application; seals leaks effectively |

| Bonding Metal Parts | Epoxy Resin | Strong adhesive properties; suitable for structural bonding |

| Sealing Concrete Cracks | Epoxy Resin | Durable and long-lasting; withstands heavy loads and harsh conditions |

| Gutter Leak Fix | Flex Seal | Simple application; flexible sealant ideal for gutters |

| Wooden Furniture Repair | Epoxy Resin | Strong bond; fills gaps and provides structural support |

| Plastic Container Repair | Flex Seal | Adheres well to various plastics; provides a waterproof seal |

4. Pros and Cons

| Aspect | Flex Seal | Epoxy Resin |

|---|---|---|

| Pros | – Easy to apply | – High strength and durability |

| – Quick drying | – Excellent chemical and heat resistance | |

| – Flexible; accommodates movement | – Strong bonding capabilities | |

| – Paintable after curing | – Long-lasting solution | |

| Cons | – May require reapplication in extreme conditions | – Requires careful mixing and application |

| – Less durable compared to epoxy | – Longer curing time | |

| – Not suitable for structural bonding | – Generally not paintable |

5. Cost Comparison

| Product | Average Cost per Unit |

|---|---|

| Flex Seal | $12–$30 per can |

| Epoxy Resin | $20–$50 per kit |

Note: Prices may vary based on brand, quantity, and retailer.

Conclusion

Choosing between Flex Seal and epoxy resin depends on the specific requirements of your project. Flex Seal offers ease of application and flexibility, making it suitable for quick fixes and sealing tasks. In contrast, epoxy resin provides superior strength and durability, ideal for structural bonding and heavy-duty waterproofing. Assess the nature of the repair, material compatibility, and environmental conditions to select the most appropriate sealant for your needs.