Does Jb Weld Work on Copper? Metal Bonding Guide

Understanding J-B Weld

Two-Part Epoxy System

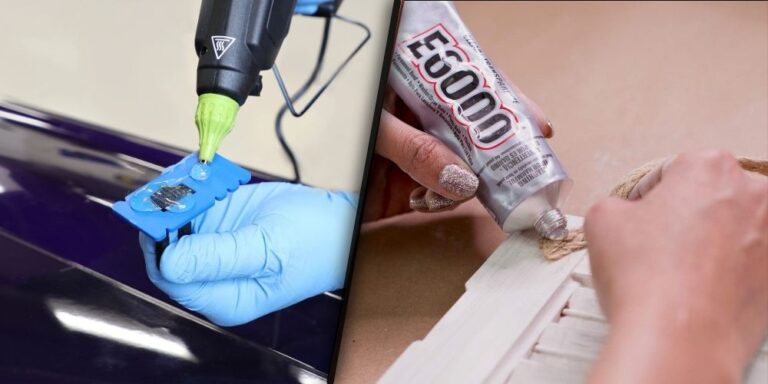

J-B Weld™ is a highly versatile adhesive renowned for its strong and lasting repairs on a variety of surfaces, including metal. This glue involves a two-part epoxy system that includes a resin and a hardener. When mixed together, these components form a robust bond that offers impressive durability. The cured product is not only strong but also machineable, meaning it can be shaped, tapped, filed, sanded, and drilled.

One of the unique features of J-B Weld is its capacity to form a permanent bond. This makes it an excellent choice for long-term repairs. The product has a curing time of 4-6 hours, and a full set time of 15-24 hours. Once cured, this epoxy can withstand temperatures up to 550°F (288°C) and has an impressive tensile strength, which we’ll discuss more in the next section.

Tensile Strength and Applications

The tensile strength of J-B Weld is 5020 PSI (J-B Weld), making it one of the strongest adhesives available for metal repairs. This high tensile strength allows J-B Weld to perform exceptionally well under stress, making it suitable for a range of applications, from automotive repairs to household fixes.

| Property | Specification |

|---|---|

| Tensile Strength | 5020 PSI |

| Temperature Limit | Up to 550°F (288°C) |

| Curing Time | 4-6 hours |

| Full Set Time | 15-24 hours |

Some common applications of J-B Weld include:

- Automotive Repairs: Ideal for fixing engine blocks, exhaust manifolds, and other metal components.

- Household Repairs: Useful for mending broken pipes, metal frames, and other home fixtures.

- Industrial Use: Frequently employed in machinery repairs and other heavy-duty applications.

For those interested in comparing different adhesives, check out our articles on jb weld vs. gorilla glue and belzona epoxy vs. jb weld epoxy.

While J-B Weld is effective on various materials, it has limitations. For instance, it generally does not work well on copper due to the material’s electrical conductivity and the presence of non-closed oxides that degrade the epoxy bond. For specific requirements, you may need to explore alternative adhesives engineered for conductive materials.

For more details on the applications and properties of different types of glue, see our articles on epoxy vs. super glue and arrow insert glue vs. super glue.

JB Weld Features

To fully understand the versatility and usability of J-B Weld, it’s crucial to look into its notable features. Here’s a detailed look at its toxicity, conductivity, and some key tips for surface preparation.

Toxicity and Food Safety

J-B Weld, once cured, is non-toxic. However, it is not rated as food-safe and should be avoided in applications that involve direct contact with food or beverages (JB Weld FAQs). This makes it suitable for many structural and functional repairs but not for environments where food safety is a concern.

| J-B Weld Feature | Status |

|---|---|

| Non-toxic when cured | Yes |

| Food-safe | No |

For those looking for information on glue products that might be safe for such uses, consider exploring wood glue vs. white glue or arrow insert glue vs. super glue.

Conductivity and Removal Methods

J-B Weld is an insulator, which means it does not conduct electricity (JB Weld FAQs). This feature makes it ideal for electrical repairs or instances where metal bonding is needed without the risk of conducting electricity. However, its non-conductive properties also mean it is not suitable for use on materials like copper that depend on electrical conductivity for performance.

For removal, once cured, J-B Weld can be challenging to remove. It is recommended to use mechanical methods like grinding, filing, or sanding. For more tips on the removal of various adhesives, check out how to remove super glue from legos.

Surface Preparation Tips

To achieve a strong bond, surface preparation is crucial, especially when dealing with materials like copper where JB Weld has limitations. Here are some essential preparation tips:

- Clean the surface to remove any dirt, oil, or residue.

- Dry the surface thoroughly.

- Roughen the area using light sandpaper or an abrasive cloth to create a textured surface for better adhesion.

| Preparation Step | Description |

|---|---|

| Clean | Remove dirt, oil, and residue |

| Dry | Ensure the surface is completely dry |

| Roughen | Use sandpaper or an abrasive cloth |

Proper preparation increases the effectiveness and durability of the bond. For more detailed steps on achieving optimal results, visit our article on surface preparation tips.

By understanding these key features of J-B Weld, users can make better-informed decisions about its applications. For comparisons with other adhesives, consider reading jb weld vs. gorilla glue and belzona epoxy vs. jb weld epoxy.

JB Weld Best Practices

Thinning JB Weld

Reducing the viscosity of JB Weld can sometimes be necessary for particular applications. JB Weld can be thinned by adding up to one teaspoon of acetone or lacquer thinner per two ounces of mixed product (JB Weld FAQs). This can aid in spreading and penetration into tighter cracks or joints, thereby improving the adhesive’s effectiveness.

JB Weld on Copper Limitation

One common question is: does JB Weld work on copper? Unfortunately, JB Weld is not ideal for copper applications. Copper’s electrical conductivity and the formation of non-closed oxides hinder the epoxy bond. The degraded bond limits JB Weld’s effectiveness, making it less reliable for structural repairs on copper surfaces.

Success Stories and Applications

Despite its limitations with copper, JB Weld has numerous success stories across various materials and scenarios. For example, a user successfully sealed a crack in a Jon boat using JB Weld above the waterline with no issues afterward. This highlights JB Weld’s impressive versatility and strength across different applications.

To achieve the best results, consider these additional best practices:

- Always ensure proper surface preparation before application.

- For safety, use heat and fire-resistant variants for specific applications.

- Select appropriate epoxy types based on the intended use and material compatibility.

For more nuanced comparisons and alternatives, explore articles like jb weld vs. gorilla glue, does jb weld work on brass, and does jb weld work on exhaust. These resources can guide users towards finding the best adhesive for their specific needs.

JB Weld Epoxy Variants

WaterWeld Epoxy

J-B Weld’s WaterWeld Epoxy is specifically formulated for underwater and wet surface repairs. This epoxy is ideal for sealing leaks in PVC pipes, tanks, and plumbing fixtures. Its effectiveness in preventing moisture leakage is well-documented. For instance, it has been used to seal areas in PVC pipes for up to a month without any leakage.

| Feature | Description |

|---|---|

| Setting Time | 15-25 minutes |

| Cure Time | 60 minutes |

| Strength | 1300 PSI |

| Temperature Resistance | Up to 300°F |

For more tips on selecting the right epoxy, refer to our detailed comparison of epoxy vs. super glue.

KwikWood Filler

KwikWood Filler by J-B Weld is designed specifically for wood repairs and bonding. This filler offers an excellent consistency and bonding capabilities, making it suitable for various DIY projects. It has been proven effective in adhering items like a palm frond to a paper mache object (JB Weld).

| Feature | Description |

|---|---|

| Setting Time | 15-25 minutes |

| Cure Time | 60 minutes |

| Strength | 900 PSI |

| Temperature Resistance | Up to 300°F |

For a broader understanding, check out our article on wood glue vs. white glue.

Proprietary Epoxy Putty

J-B Weld offers a proprietary epoxy putty known as SteelStik. This variant is versatile and can be used for numerous applications including sealing, patching, and bonding various materials. Similar to the WaterWeld, it can also seal PVC pipes with no moisture leakage after a month of monitoring (JB Weld).

| Feature | Description |

|---|---|

| Setting Time | 5 minutes |

| Cure Time | 1 hour |

| Strength | 900 PSI |

| Temperature Resistance | Up to 300°F |

For additional insights and comparisons, explore our guide on how long does it take for jb weld to dry.

By understanding the various JB Weld epoxy variants, you can select the most appropriate product for your specific needs, especially for tasks that involve bonding copper or other metals. For questions like “does JB Weld work on copper?” refer to our comprehensive guide.

Achieving Optimal Results

Achieving the best possible results when using J-B Weld involves a combination of proper surface preparation, understanding bond strength and endurance, and comparing different glue types.

Surface Preparation Steps

Properly preparing the surface is critical for ensuring a strong and durable bond when using J-B Weld. Follow these steps for optimal surface preparation:

- Clean the Surface: Use a detergent or degreaser to remove any dirt, grease, or oil from the copper surface. This ensures the adhesive can bond directly to the copper and not the contaminants.

- Roughen the Surface: Use a file or coarse sandpaper to roughen the copper surface. Creating a rough texture increases the surface area, which improves the adhesive grip.

- Dry the Surface: Ensure the surface is completely dry before applying J-B Weld. Moisture can prevent the epoxy from setting correctly.

By following these surface preparation steps, you can maximize the effectiveness of J-B Weld on copper.

Bond Strength and Endurance

J-B Weld’s epoxies are known for their high tensile strength and durability. They create incredibly strong bonds due to reactive chemistry, making them suitable for a wide range of materials.

Epoxies have some of the highest PSI (Pounds Per Square Inch) ratings among adhesives, implying strong resistance to force from any direction (shear strength). This makes J-B Weld a reliable option for creating lasting bonds.

| Adhesive Type | PSI Rating | Shear Strength |

|---|---|---|

| Epoxy (J-B Weld) | 5020 | High |

| Super Glue | 2000 | Medium |

| Gorilla Glue | 3000 | Medium-High |

Comparing Different Glue Types

Choosing the best adhesive involves comparing different glue types based on their properties and performance. Below is a comparison of some common glue types:

- Epoxy (J-B Weld): Offers the highest bond strength and versatility. Suitable for metals, ceramics, wood, and more. Known for its durability and ability to withstand various environmental conditions.

- Super Glue: Dries quickly and provides a strong bond for small, lightweight items. Best for quick fixes but may not offer the same level of durability as epoxy.

- Gorilla Glue: Expands as it dries, which can fill gaps but may be difficult to control. Provides a strong bond for porous and non-porous surfaces.

For a more detailed comparison, you can explore jb weld vs. gorilla glue or epoxy vs. super glue.

By understanding these differences and following best practices, you can successfully use J-B Weld for various applications, particularly on copper and other metals. For more details on specific applications, check out our guide on does jb weld work on brass.