Belzona Epoxy vs. JB Weld Epoxy: Strength Test

Understanding Epoxy Adhesives

Epoxy adhesives are widely used for their strong bonding properties and versatility. Understanding what epoxy is and where it can be used will help you choose the right adhesive for your project.

Defining Epoxy

Epoxy is a type of adhesive that consists of two main components: resin and hardener. When these two components are mixed, they undergo a chemical reaction that forms a strong and durable bond. Unlike other adhesives, epoxy adhesives can bond to a variety of materials including metal, wood, plastic, and ceramics.

Epoxies are known for their high strength, excellent resistance to environmental factors such as moisture and temperature, and their ability to fill gaps and create a smooth finish. These properties make them suitable for both industrial applications and household repairs.

Common Uses

Epoxy adhesives have a wide range of applications, from simple household repairs to complex industrial uses. Some common applications include:

- Automotive Repairs: Epoxies are often used to repair cracks in metal components and to bond various parts together.

- Construction: In construction, epoxy adhesives are used to bond concrete, fix structural components, and seal surfaces.

- Crafts and Hobbies: Due to their strong bonding capabilities, epoxies are popular among hobbyists for tasks such as model building, including in specialized fields like rocketry (Rocketry Forum).

- Marine Applications: Epoxies are resistant to water and are used for boat repairs and other marine-related applications.

| Application | Example Use |

|---|---|

| Automotive | Repair cracks in engine parts |

| Construction | Bond concrete and structural components |

| Crafts and Hobbies | Model building and rocketry projects |

| Marine | Boat repairs and sealing surfaces |

In the competition of Belzona Epoxy vs. JB Weld Epoxy, understanding these common uses and the general properties of epoxy adhesives sets the stage for a deeper comparison of these two popular products. For more insights on how epoxies stack up against other adhesives, visit our comparison on epoxy vs. super glue and other related articles.

Belzona Epoxy

Features of Belzona

Belzona epoxy is renowned for its outstanding chemical resistance and durability, making it a preferred choice for a plethora of industrial applications. The unique features of Belzona epoxy set it apart as a reliable solution for maintenance and repair needs.

- Exceptional Chemical Resistance: Belzona epoxy can withstand a variety of harsh chemicals, ensuring long-lasting protection and performance in corrosive environments. (Belzona)

- Durability: Known for its robustness, Belzona epoxy offers strong adhesion and mechanical strength, making it ideal for repairing and rebuilding components.

- Cold Curing: One of the standout features of Belzona epoxy is its ability to cure at room temperature, eliminating the need for heat treatments.

- Rapid Return to Service: With fast curing times, structures and machinery can be returned to service quickly after repair, minimizing downtime. (Belzona)

Applications of Belzona

Due to its high performance and versatile nature, Belzona epoxy is used in various industrial sectors. Below are some common applications:

- Corrosion Protection: Belzona epoxy provides a protective barrier against oxidation and other corrosive elements, extending the life of equipment.

- Machinery Repair: It is frequently used to fix damaged machinery, restoring original dimensions and functional integrity. (Belzona)

- Rebuilding Components: Belzona epoxy can effectively rebuild worn-out components, bringing them back to their original specs and improving performance.

- Erosion and Mechanical Damage Repair: It offers long-lasting solutions for erosion, corrosion, and mechanical damage, proving its effectiveness in challenging environments. (Belzona)

For a detailed comparison between Belzona epoxy and other adhesives, visit our page on jb weld vs. gorilla glue. Additionally, to explore more about its comparative strength, you can review various user experiences in our case studies.

JB Weld Epoxy

Features of JB Weld

JB Weld is a popular epoxy known for its strong bond and versatility. It is a two-part epoxy system composed of resin and hardener. Users often appreciate its easy application and durable results, making it a favorite in various DIY and repair projects.

Here are some notable features of JB Weld:

- High Strength: JB Weld provides a formidable bond that can withstand extreme pressures and temperatures.

- Temperature Resistance: It performs well under high heat, remaining stable even at temperatures up to 550°F (287°C).

- Setting Time: JB Weld typically sets in 4-6 hours and cures fully in 15-24 hours.

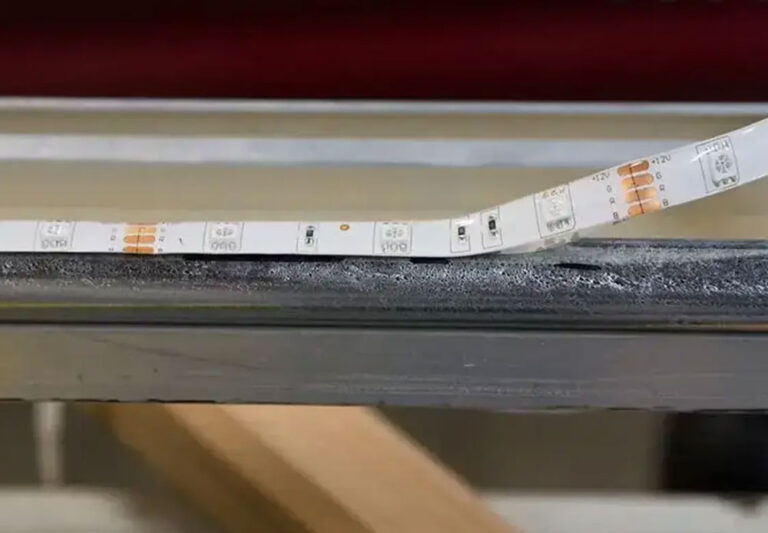

- Multi-Surface Use: Suitable for a variety of materials including metal, wood, plastic, and ceramics.

- Waterproof: Once cured, JB Weld becomes impervious to water, making it ideal for applications that involve moisture.

- Chemical Resistance: Resistant to chemicals, ensuring longevity even in harsh environments.

Applications of JB Weld

JB Weld epoxy is widely used for its robustness and reliability in diverse applications. Its utility spans from household repairs to industrial use, making it a go-to adhesive for many.

Here are some common applications of JB Weld:

| Application | Description |

|---|---|

| Automotive Repairs | Ideal for fixing engine parts, radiators, and exhaust systems. |

| Plumbing | Useful in repairing leaks and joining pipes. |

| Metal Fabrication | Effective in bonding various metal components. |

| Electronics | Utilized in securing components and repairing plastic housings. |

| Woodworking | Employed for repairing furniture and bonding wooden parts. |

| Ceramic and Brick | Efficient in sealing cracks and bonding surfaces. |

For those interested in comparing JB Weld with other adhesives, exploring articles like jb weld vs. gorilla glue or pc 7 epoxy vs. jb weld can provide valuable insights.

JB Weld’s reliability extends to specialized uses in fields such as rocketry. According to discussions on the Rocketry Forum, both JB Weld and other epoxies are favored for their strong adhesive properties in constructing and repairing rockets.

For users seeking to understand more about epoxy applications or alternatives, considering reads like epoxy vs. super glue can further illuminate how different adhesives compare in terms of strengths and suitable uses.

Belzona vs. JB Weld

Strength and Durability

When comparing Belzona Epoxy and JB Weld Epoxy, strength and durability are crucial factors to consider. Both adhesives have built a strong reputation in the market, but they differ in key aspects that might influence your choice.

Strength Comparison

Belzona is known for its superior bonding strength, especially in industrial applications. It is often used in situations requiring high resistance to abrasion and mechanical stress, according to discussions on PracticalMachinist Forum.

JB Weld, on the other hand, is highly regarded for its tensile strength, which makes it a favorite for everyday repairs and moderate industrial uses. JB Weld can withstand a tensile strength of 3960 PSI.

| Product | Tensile Strength (PSI) |

|---|---|

| Belzona Epoxy | 4300 |

| JB Weld Epoxy | 3960 |

Durability

Belzona sets itself apart with excellent resistance to harsh environmental conditions, including chemicals, extreme temperatures, and moisture. This makes it particularly suitable for heavy-duty applications such as machinery repair and marine environments (EAA Forums).

JB Weld also provides good resistance to environmental factors but is generally used in less demanding conditions. It performs well under heat and pressure, which makes it a versatile option for most household and automotive repairs.

For more information about the comparison of different adhesives, you may explore our article on epoxy vs. super glue.

Versatility

Another important factor to consider when comparing Belzona Epoxy and JB Weld Epoxy is versatility. Both products offer distinct advantages depending on the application.

Range of Applications

Belzona is tailored for more specialized use, often recommended for high-performance needs such as industrial equipment restoration, chemical containment, and heavy-duty maintenance (HomeBrewTalk). Its formulations are designed to adhere to various surfaces including metal, concrete, and composites, making it a go-to solution for challenging repair works.

JB Weld’s versatility lies in its widespread use among DIY enthusiasts and professionals alike. It works effectively on a multitude of surfaces including metal, wood, plastic, and ceramic. From automotive repairs to household fixes, JB Weld proves to be a handy adhesive for a plethora of projects (HomeBarista Forums).

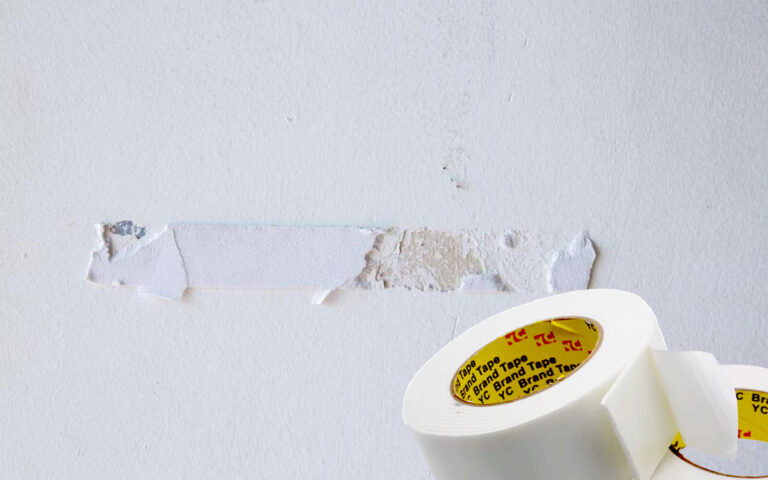

Ease of Use

When it comes to ease of application, JB Weld is often favored for its user-friendly properties. It comes in various forms such as putty, liquid adhesive, and syringe applicators, offering convenience for different repair needs. The product is also relatively quick to set and cure, making it ideal for emergency repairs.

Belzona, although highly effective, usually requires a more cautious approach. It often involves multiple steps for preparation and application, which might require professional assistance or more technical knowledge.

To explore other comparable adhesive options, read our discussions on jb weld vs. gorilla glue and bondo vs. jb weld.

Understanding the unique strengths and versatility of Belzona and JB Weld can help you make an informed decision for your specific adhesive needs. Whether you are looking for high-performance industrial solutions or reliable household repairs, aligning the properties of these epoxies with your project requirements is essential. For detailed guides on how to properly use these adhesives, please refer to our other informative articles available through the embedded internal links.

Choosing the Right Epoxy

Selecting the right epoxy adhesive depends on various factors and considerations. Here’s an in-depth guide to help you make an informed decision between Belzona Epoxy and JB Weld Epoxy.

Factors to Consider

When deciding between Belzona Epoxy and JB Weld Epoxy, consider the following factors:

-

Strength and Durability: Assess the strength and durability required for your specific application. Belzona Epoxy is known for its high-performance industrial applications, while JB Weld is popular for its metal bonding capabilities.

-

Cure Time: Consider how quickly the epoxy needs to set. JB Weld typically has a longer cure time, allowing for adjustments during application. Belzona products often cure faster, which can be beneficial for urgent repairs.

-

Temperature Resistance: Evaluate the temperature conditions the epoxy will be exposed to. Both epoxies offer high-temperature resistance, but Belzona is specifically designed for extreme environments.

-

Ease of Use: User-friendliness can be a crucial factor. JB Weld is known for its simple application process, making it suitable for DIY projects. Belzona, on the other hand, may require professional handling.

-

Cost: Factor in the cost for each option. While Belzona might come at a higher price due to its industrial-grade quality, JB Weld is generally more affordable for everyday repairs.

| Criteria | Belzona Epoxy | JB Weld Epoxy |

|---|---|---|

| Strength | High | Moderate to High |

| Cure Time | Fast | Slower |

| Temperature Resistance | Extreme | High |

| Ease of Use | Professional Application | DIY-Friendly |

| Cost | Higher | More Affordable |

Decision Making

Making the right choice between Belzona Epoxy vs. JB Weld Epoxy involves weighing these factors against the specific requirements of your project.

-

Industrial Applications: For industrial-strength bonding and repairs, Belzona is the superior choice due to its robustness and special formulation for extreme conditions.

-

DIY Projects: For general home repairs or DIY projects, JB Weld offers the versatility and ease of use suitable for hobbyists and non-professionals.

For additional insights about glue comparisons, refer to our related articles on loctite pl marine vs. 5200 and arrow insert glue vs. super glue. These resources can provide further understanding of various adhesive options and their applications.