Shoe Goo vs Shoe Goo II: Formula Comparison Guide

Shoe Goo Characteristics

Composition Overview

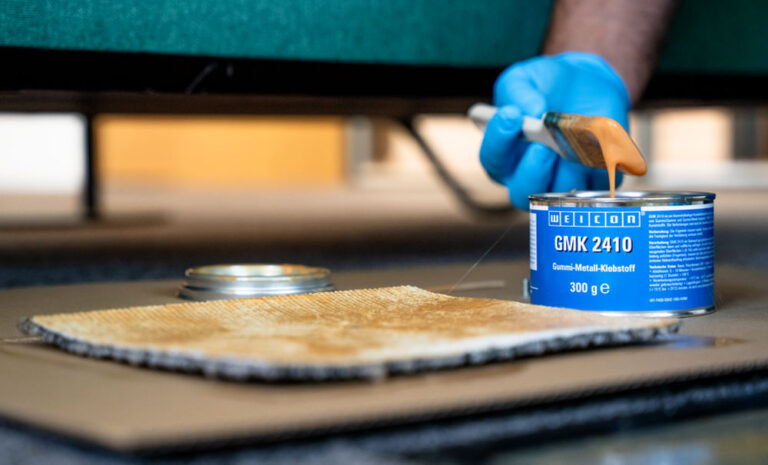

Shoe Goo employs a unique blend of adhesives to deliver a reliable and robust solution for shoe repairs. One notable reference comes from Nike, which uses a mix of hot melt adhesive and polyurethane adhesive in their shoes. For low-impact areas, hot melt adhesive is applied to keep the shoe parts together. In contrast, polyurethane adhesive is used in high-stress zones, like the soles, to create a durable bond that withstands significant force before failing (Quora). While Shoe Goo’s precise formula may vary, it follows a similar principle to provide a strong, flexible, and long-lasting adhesive solution.

Features of Shoe Goo

Shoe Goo offers several features for effective shoe repairs:

- Water Resistance: Shoe Goo is specifically designed to offer a flexible, waterproof bond, making it ideal for quick fixes and customizations.

- Quick Drying Time: One of the standout features is its faster drying time, which makes it convenient for urgent repairs. However, it may harden and become brittle over time (Stickyn).

- Flexibility: Ideal for sports shoes, Shoe Goo provides a robust bond that remains pliable, crucial for activities requiring frequent movement.

- Durability: While mainly used for footwear, it’s also great for leather and rubber boots. The product ensures that soles remain sturdy, extending the lifespan of various shoe types.

| Feature | Characteristics |

|---|---|

| Water Resistance | Waterproof, suitable for all weather conditions |

| Drying Time | Fast-drying, suitable for urgent repairs |

| Flexibility | Remains pliable, ideal for sports and outdoor shoes |

| Durability | Long-lasting bond, extends the life of shoes |

Customers often appreciate the adhesive quality of Shoe Goo. They note its strong, flexible bond that works excellently for sports shoes and urgent repairs. Reviews also highlight that it dries fast, remains pliable, and is 100% waterproof.

For further insights on comparing different adhesives, you might find our articles on rubber cement vs contact cement and barge cement vs shoe goo informative.

Shoe Goo vs. Shoe Goo II

When it comes to comparing Shoe Goo and Shoe Goo II, both products have their unique strengths. The primary differences lie in their drying time and durability.

Speed of Drying

Shoe Goo is typically preferred for urgent repairs due to its faster drying time. It dries quickly, making it suitable for quick fixes and less detailed applications. Customers appreciate that Shoe Goo dries fast and mention its versatility in sticking well.

In contrast, Shoe Goo II takes longer to dry. It can require up to 24 hours for a full cure, depending on the application thickness and environmental conditions (Stickyn). This extended drying time can be a consideration for those needing immediate use of the repaired item.

| Product | Drying Time |

|---|---|

| Shoe Goo | Faster (Quick fixes) |

| Shoe Goo II | Slower (Up to 24 hours) |

Durability and Longevity

Both Shoe Goo and Shoe Goo II offer strong adhesive capabilities, but they differ in regard to durability and longevity.

Shoe Goo is known for its flexibility and waterproof nature, making it ideal for shoe repairs. However, over time, it can harden and become brittle, which may compromise its durability. This makes it more suitable for temporary fixes and repairs that do not require long-term durability.

Shoe Goo II, on the other hand, is designed with a focus on enhanced durability and longevity. It may take longer to dry, but the bond it forms is strong and long-lasting. This makes it a better choice for repairs that need to withstand regular wear and tear. The added UV resistance in Shoe Goo II also contributes to its long-term performance, reducing the chances of the adhesive breaking down under sunlight exposure.

| Product | Durability & Longevity |

|---|---|

| Shoe Goo | Flexible but may harden over time |

| Shoe Goo II | Enhanced durability, UV resistant |

To further explore detailed comparisons between these products and others, you may find our articles on related adhesives useful, such as e6000 vs shoe goo and barge cement vs shoe goo.

Shoe Goo Applications

Shoe Repairs

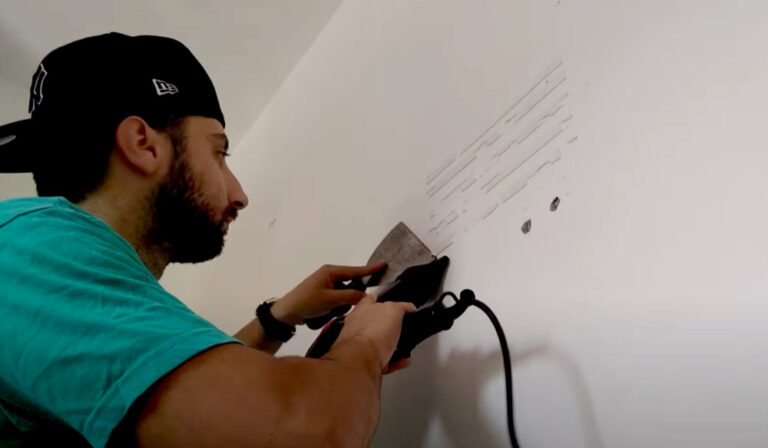

Shoe Goo is highly recommended for various footwear repairs. Customers have noted its effectiveness in extending the life of leather and rubber boots, particularly in reinforcing and repairing soles. This adhesive excels in fixing shoes that are falling apart, ensuring a durable bond that prevents further wear (Amazon).

Nike employs a combination of hot melt adhesive and polyurethane adhesive in their shoes. In low impact areas, hot melt adhesive holds the shoe’s components together, while polyurethane adhesive is used in high-stress areas like the sole, providing a robust bond that can withstand significant force. Shoe Goo mirrors this dual-functionality with a flexible, waterproof bond that addresses common shoe issues, making it ideal for quick fixes and customizations. Its faster drying time allows for convenient and urgent repairs.

Below is a table summarizing Shoe Goo’s application effectiveness:

| Repair Type | Customer Feedback |

|---|---|

| Leather Boots | Excellent |

| Rubber Boots | Excellent |

| Sole Reinforcement | Excellent |

| General Shoe Repair | Very Good |

For more details on the type of adhesives used by different brands, consider reading loctite 510 vs. 515.

Customization Projects

Shoe Goo is also suitable for shoe customization projects. While customer feedback on durability varies, many appreciate the adhesive’s fast drying time and its capacity to hold up well in various customization tasks. Some users have had success in creating unique designs and reinforcing custom elements, although others have experienced issues with the adhesive cracking or the seams coming apart.

| Customization Aspect | Customer Feedback |

|---|---|

| Bonding Strength | Mixed |

| Functionality | Positive |

| Durability | Mixed |

For more advice on applying adhesives to different materials, check out our article on contact cement vs. rubber cement.

Whether you are fixing a well-worn pair of boots or personalizing your favorite sneakers, Shoe Goo provides a versatile solution. Remember to explore other adhesives and their applications, such as 3m 4200 vs. 5200 and liquid nails vs. pl premium, to find the best fit for your needs.

Shoe Goo II Benefits

When it comes to repairing footwear, Shoe Goo II offers distinct benefits that make it a favored choice for various applications.

Water and UV Resistance

Shoe Goo II provides excellent water and UV resistance, making it especially useful for outdoor and athletic footwear. This enhanced resistance ensures that the adhesive maintains its bond even in harsh weather conditions and prolonged sun exposure, offering robust solutions for shoe repairs under various conditions (Stickyn).

| Feature | Shoe Goo | Shoe Goo II |

|---|---|---|

| Water Resistance | High | Excellent |

| UV Resistance | Medium | Excellent |

For users seeking adhesives that endure outdoor activities, Shoe Goo II proves to be particularly reliable. Learn more about how it compares with other products in our article on aquaseal vs shoe goo.

Flexibility and Versatility

One of the standout attributes of Shoe Goo II is its exceptional flexibility. This adhesive is designed to accommodate areas that require significant movement and flexibility, such as the soles and uppers of athletic and outdoor shoes. Its ability to flex without cracking makes it highly versatile.

| Feature | Shoe Goo | Shoe Goo II |

|---|---|---|

| Flexibility | High | Extreme |

| Versatility | High | Extreme |

Shoe Goo II’s flexibility and durable bond make it ideal for various shoe repair needs, including those that demand a high degree of adaptability. For additional insights into its performance, check out our article on barge cement vs shoe goo and other comparisons like e6000 vs shoe goo.

By leveraging these benefits, Shoe Goo II becomes a reliable option for anyone seeking durable and flexible adhesive solutions for their footwear. Whether it’s dealing with the rigors of outdoor activities or requiring a robust repair for everyday shoes, Shoe Goo II delivers with confidence. Explore more about adhesives and their applications in articles such as liquid nails vs. pl premium and loctite 510 vs. 515.

Shoe Goo vs. Aquaseal

In evaluating adhesives for gear and footwear repairs, comparing Shoe Goo to Aquaseal presents a clear picture of their respective strengths, ideal uses, and performance characteristics.

Outdoor Gear Repairs

Aquaseal is widely recommended for outdoor gear repairs due to its standout durability, flexibility, and waterproof capabilities. It excels in fixing items like waders, wetsuits, and tents. Aquaseal’s rugged, waterproof seal withstands the dynamic nature of outdoor activities, making it suitable for materials that stretch and flex, such as neoprene fabric. This flexibility remains even after curing, adapting to the movement of the materials it bonds (source).

On the other hand, while Shoe Goo also has good waterproofing properties and can be used in various applications, it is primarily designed for footwear repairs. It is versatile and effective on synthetic materials and even for minor household repairs, such as craft projects (source).

Here’s a brief comparison of suitable repair projects:

| Repair Type | Aquaseal | Shoe Goo |

|---|---|---|

| Outdoor Gear (Waders, Tents, etc.) | Excellent | Adequate |

| Footwear | Good | Excellent |

| Neoprene, Synthetic Fabrics | Excellent | Good |

| Craft Projects | Good | Good |

Drying Times and Curing

Drying time and curing duration are essential factors when choosing an adhesive, as they directly impact usability and convenience.

Aquaseal generally requires a longer drying period, typically taking around 8-12 hours for a full cure. This extended curing time contributes to its strong, durable bond and superior flexibility.

Conversely, Shoe Goo is more convenient for quick fixes as it dries faster, typically within 24 hours. However, while this rapid drying time is advantageous for immediate repairs, it can result in a somewhat less durable bond compared to Aquaseal.

| Adhesive | Drying Time | Full Cure Time |

|---|---|---|

| Aquaseal | 8-12 hours | 24 hours |

| Shoe Goo | 4-6 hours | 24 hours |

For users in need of immediate, short-term fixes and general household applications, Shoe Goo’s faster drying time may be more suitable. However, for those requiring robust, long-lasting repairs on outdoor equipment, the wait time for Aquaseal’s superior bond is well worth it.

For more comparisons on adhesives, check out aquaseal vs shoe goo and other similar articles like e6000 vs shoe goo for detailed insights.

Customer Perspectives

Feedback on Shoe Goo

Customer feedback on Shoe Goo is varied, with responses largely depending on user expectations and the specific use cases of the adhesive. Some users have noted its strong adhesive qualities, emphasizing its flexible and waterproof properties ideal for quick fixes and customizing shoes. Many users appreciate its effectiveness, especially for athletic footwear, highlighting how it acts as a reliable bonding agent.

However, not all feedback is entirely positive. A segment of users has reported mixed reactions, particularly regarding its long-term performance. Some customers mention that their shoes came apart at the seams, indicating possible issues with adhesion longevity. This is particularly noted in outdoor settings where shoes experience extensive wear and tear (Amazon).

For those using Shoe Goo for casual or non-intensive applications, the feedback tends to lean more favorably. Users report satisfaction with its ability to handle minor repairs and aesthetic enhancements proficiently.

Reviews on Durability

Durability is a significant consideration when comparing Shoe Goo vs Shoe Goo II. Reviews are mixed, showcasing both strengths and weaknesses:

-

Positive Durability Reviews:

-

Many customers highlight that Shoe Goo performs exceptionally well for short-term fixes, providing a sturdy and flexible bond.

-

Users who have employed it for customization projects praise its ability to maintain flexibility without compromising the adhesive quality.

-

Negative Durability Reviews:

-

Several users have reported that while Shoe Goo initially provides a strong bond, it might harden and become brittle over time. This could lead to cracks, especially under stress or frequent use (Stickyn).

-

Some feedback indicates that heavy-duty applications, such as those required for sports shoes, sometimes result in the adhesive failing, particularly at the seams.

| Feedback Category | Positive (%) | Negative (%) |

|---|---|---|

| Adhesive Quality | 75 | 25 |

| Flexibility | 70 | 30 |

| Durability | 60 | 40 |

For more in-depth comparisons with other adhesives, you may find our articles on aquaseal vs shoe goo and e6000 vs shoe goo useful. Additionally, please check out our guide on liquid nails vs. pl premium for broader adhesive comparisons.