E6000 vs Shoe Goo: Ultimate Adhesive Comparison

E6000 vs. Shoe Goo: A Comparison

When it comes to choosing the right adhesive for your project, understanding the specific properties and applications of different adhesives is crucial. In this section, we compare two popular adhesives: E6000 and Shoe Goo.

Understanding E6000 Adhesive

E6000 is an industrial-strength adhesive known for its strong bonding capabilities and exceptional flexibility. This adhesive is highly recommended for high-stress applications such as armor crafting due to its robust bonding properties. Additionally, E6000 dries to a rubber-like consistency, which allows it to resist cracking under stress. This makes it suitable for projects requiring some degree of movement.

Key properties of E6000:

- Industrial-strength bonding

- Flexible and durable

- Dries clear and waterproof

- Suitable for a variety of materials including leather and rubber (Quora)

| Property | E6000 |

|---|---|

| Bonding Strength | High |

| Flexibility | High |

| Drying Time | Moderate |

| Waterproof | Yes |

| Suitable Materials | Leather, Rubber, Plastic, Metal |

For more information on how to use E6000 for different applications, check out our guides on how to use E6000 glue on wood and how to use E6000 glue on plastic.

Exploring Shoe Goo

Shoe Goo is a specialized adhesive designed specifically for repairing footwear. It is known for its flexibility, waterproofing benefits, and durability. This makes it ideal for repairing outdoor shoes and boots that face harsh environments (NuShoe).

Key properties of Shoe Goo:

- Flexible adhesive suitable for shoe repair

- Provides waterproofing benefits

- Highly durable

- Ideal for use on outdoor shoes and boots

| Property | Shoe Goo |

|---|---|

| Bonding Strength | Moderate |

| Flexibility | High |

| Drying Time | Slow |

| Waterproof | Yes |

| Suitable Materials | Leather, Rubber, Fabric |

For additional tips on using adhesives for footwear, see our comparison between aquaseal vs shoe goo and barge cement vs shoe goo.

By understanding the properties and applications of both E6000 and Shoe Goo, you can make an informed decision about which adhesive is best suited for your particular needs. For more comparisons of various glues and adhesives, explore our other topics such as liquid nails vs. pl premium and loctite 510 vs. 518.

Properties of E6000

Bonding Strength of E6000

E6000 adhesive is known for its exceptionally strong bonding capabilities, particularly in high-stress applications. Its industrial-strength allows it to adhere strongly to various materials, making it ideal for projects that require durable and flexible bonds (Stickyn). It can withstand significant stress and strain, which is why it’s often recommended for applications such as shoe repair and even armor crafting.

When comparing E6000 vs. Shoe Goo, E6000 tends to last longer and handles multiple resoles better than Shoe Goo.

Drying Time of E6000

The drying time for E6000 can vary based on environmental conditions and the materials being bonded. Typically, E6000 will achieve initial bond strength within 4-8 hours but requires a full 24 to 72 hours to cure completely.

| Drying Stage | Estimated Time |

|---|---|

| Initial Bond | 4-8 hours |

| Full Cure | 24-72 hours |

This extended curing period allows the adhesive to form a robust and flexible bond, necessary for applications that endure stress and movement.

Odor Considerations

One of the aspects users need to be aware of when using E6000 is its strong odor. Traditional E6000 uses solvents that emit a noticeable smell, necessitating good ventilation for indoor use (Stickyn). However, E6000 Plus, which utilizes premium polymer technology, is virtually odorless and safer for indoor projects.

For more details on adhesives suitable for various conditions and applications, explore our articles on liquid nails vs. pl premium and loctite blue vs. red.

Applications of E6000

E6000 adhesive is renowned for its versatility and strength, making it suitable for a wide range of applications. This section explores the industrial-strength uses of E6000 and how it performs in shoe repair.

Industrial-Strength Uses

E6000 is highly favored for high-stress applications due to its industrial-strength bonding capabilities and flexibility. Its adhesive properties make it ideal for projects requiring tough and flexible bonds, such as armor crafting and various DIY projects.

| Application | Strength | Flexibility |

|---|---|---|

| Armor Crafting | High | High |

| Jewelry Making | Medium | Medium |

| DIY Projects | Varies | Varies |

The adhesive’s durability and ability to resist cracking under stress are key features that make it suitable for items experiencing movement or constant handling. Its rubber-like consistency when dried ensures flexibility without compromising on strength.

For those considering indoor projects, it’s important to note that E6000 has a strong odor due to solvents, thus good ventilation is required. Alternatively, the E6000 Plus variant uses premium polymer technology, making it virtually odorless and safer for indoor use.

Shoe Repair with E6000

Repairing shoes using E6000 is a cost-effective and sustainable solution. By opting for adhesive repair instead of purchasing new footwear, significant cost savings can be achieved. For instance, quality shoe adhesive, such as Loctite Shoe Glue, costs around $6.58, while new shoes can range from $50 to $100 or more (NuShoe).

| Repair Option | Cost Savings |

|---|---|

| E6000 Adhesive | High |

| New Shoes | Low |

E6000’s bonding strength and flexibility make it particularly effective for shoe repairs. It can extend the life of footwear by up to 50%, according to a NuShoe study (NuShoe). This not only reduces waste but also promotes sustainability through repair.

To explore more about other adhesives for shoe repair, visit our guide on aquaseal vs shoe goo.

For more information on how E6000 stands up against other adhesives, you can check out our comparisons like gem tac vs. e6000 and gs hypo cement vs. e6000. These insights can help in selecting the appropriate adhesive for diverse needs.

By understanding the different uses of E6000, one can appreciate its versatility and strong adhesive properties, making it a suitable choice for both industrial-grade projects and practical footwear repairs.

Qualities of Shoe Goo

In the debate of E6000 vs. Shoe Goo, Shoe Goo stands out for its unique qualities that make it a go-to option for shoe repair. Understanding the flexibility, waterproofing benefits, and durability of Shoe Goo can help you decide if it’s the right adhesive for your needs.

Flexibility of Shoe Goo

Shoe Goo is known for its remarkable flexibility. Because of this, it is an excellent choice for re-attaching shoe soles or repairing other parts of footwear that experience constant movement and flexing. This flexibility ensures that the bond remains intact even under stress, making it particularly suitable for athletic shoes or any footwear subjected to rigorous use.

| Property | Flexibility |

|---|---|

| Shoe Goo | High |

| Gorilla Glue | Moderate |

Waterproofing Benefits

Another standout feature of Shoe Goo is its waterproofing capabilities. It forms a robust, waterproof barrier that helps protect repaired areas from moisture and water damage. This makes Shoe Goo ideal for repairing outdoor gear and shoes that encounter wet conditions. Given that shoes often come in contact with water, whether from rain or puddles, having an adhesive that resists water is a significant advantage.

Durability of Shoe Goo

Durability is a critical aspect when choosing an adhesive for shoe repair. Shoe Goo creates a strong, long-lasting bond that is resilient against the wear and tear of daily use. Its durability ensures that repairs don’t require frequent reapplications, providing a more permanent solution. This is why many professional shoe repair shops often use durable adhesives like Shoe Goo or Barge All-Purpose Cement, both known for their strong and lasting bonds.

| Property | Durability |

|---|---|

| Shoe Goo | High |

| E6000 | High |

When choosing between E6000 and Shoe Goo, it’s essential to consider these unique qualities and how they align with your specific needs. For more insights on other adhesives, explore our comparisons like barge cement vs. contact cement and rubber cement vs contact cement.

Selecting the Right Glue

When it comes to choosing between E6000 and Shoe Goo, there are several critical factors to consider. Understanding these criteria will help you make an informed decision based on your specific project needs.

Factors for Consideration

- Bonding Strength

- E6000: Known for its industrial-strength bonding, E6000 is suitable for high-stress applications. It is particularly recommended for projects like armor crafting due to its durable and flexible bond.

- Shoe Goo: Provides a durable and flexible bond, which is essential for shoe repairs. The adhesive ensures the bond remains intact despite the movement and stress that shoes undergo.

- Drying and Curing Time

- E6000: Initial bond strength can be achieved in 4-8 hours, with full curing taking 24 to 72 hours depending on environmental conditions and materials.

- Shoe Goo: Typically dries within a few hours and reaches full strength in 24 hours, making it convenient for quick repairs.

- Odor and Safety

- E6000: Contains strong solvents, resulting in a noticeable odor that requires good ventilation for indoor use. E6000 Plus, however, utilizes a premium polymer technology, making it virtually odorless.

- Shoe Goo: Also has a noticeable odor due to solvents, but ventilation can mitigate this issue during application.

- Flexibility and Durability

- E6000: Dries to a rubber-like consistency that remains flexible and resists cracking under stress, ideal for projects needing some degree of movement.

- Shoe Goo: Renowned for its flexibility, it seals and repairs shoes effectively while maintaining durability through various conditions.

| Factor | E6000 | Shoe Goo |

|---|---|---|

| Bonding Strength | Industrial-strength | Durable, flexible for shoes |

| Drying Time | 4-8 hours (initial), 24-72 hours (full) | A few hours, 24 hours (full) |

| Odor and Safety | Strong solvents (E6000 Plus: odorless) | Strong solvents |

| Flexibility/Durability | Rubber-like, flexible | Highly flexible |

Expert Recommendations

- For High-Stress Applications: E6000 is recommended due to its industrial-strength bond and flexibility, making it perfect for tasks that involve heavy-duty material bonding.

- For Shoe Repairs: Shoe Goo is specifically designed for repairing footwear. Its flexibility and waterproof nature ensure that shoes remain functional and durable, even with regular wear (NuShoe).

- For Indoor Projects: E6000 Plus, with its virtually odorless formulation, is safer for indoor projects requiring a strong, flexible bond.

Choosing the right adhesive depends on the specific requirements of your project. If you need an adhesive for high-stress applications or flexible joints, E6000 is ideal. Meanwhile, for shoe repairs or projects needing a quick and flexible fix, Shoe Goo should be your choice. For more on similar comparisons, read our article on liquid nails vs. pl premium.

Environmental Impact

When considering the use of adhesives such as E6000 or Shoe Goo, it’s worth noting their broader environmental impact. Repairing items instead of discarding them contributes to a more sustainable lifestyle and promotes social responsibility.

Social Responsibility in Repair

Repairing shoes using the right adhesive not only extends the life of the footwear but also addresses an environmentally responsible ethos. According to NuShoe, repairing shoes reduces the demand for new products, thereby conserving valuable resources in the manufacturing process.

A study by NuShoe found that shoe repair can extend the life of footwear by up to 50%, leading to a substantial reduction in waste. By making simple repairs with Shoe Goo or E6000, consumers can play a pivotal role in reducing the environmental footprint associated with the production and disposal of shoes.

Sustainability through Repair

Sustainability is a key consideration when choosing between E6000 vs. Shoe Goo. Repairing items instead of purchasing new ones not only conserves resources but also minimizes waste. For instance, repairing shoes with quality adhesive can save significant costs. Loctite Shoe Glue, for example, costs around $6.58, whereas new shoes can range between $50 to $100 or more.

The use of adhesives for repair also supports the longevity of various items, from footwear to outdoor gear. This can be seen in products like Aquaseal, which is ideal for permanent repairs on a wide range of materials, offering superior durability and abrasion resistance, making it perfect for items like wet suits and water sports gear.

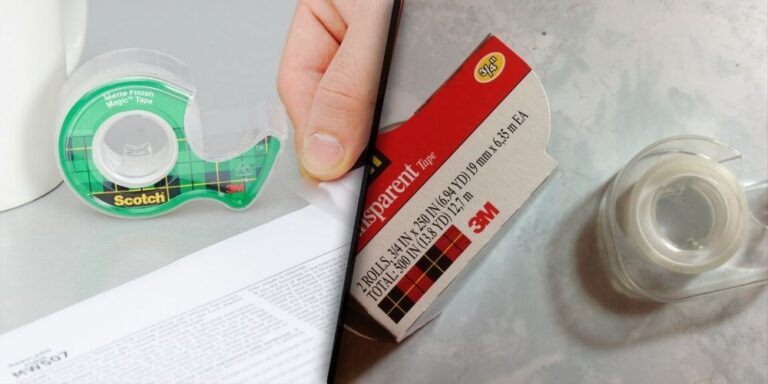

By selecting the right adhesive for specific repair needs, individuals can significantly contribute to environmental sustainability. For more information on this, you can read our comparison articles like barge cement vs contact cement and masking tape vs scotch tape.