How To Use E6000 Glue on Glass: Perfect Bond Guide

Understanding E6000 Glue

E6000 glue is a powerful adhesive known for its versatility and strong bonding capabilities. It is often used in various DIY projects, crafts, automotive repairs, and more. This section explores the different types of E6000 glue available and shares some success stories that highlight its effectiveness.

Types of E6000 Glue

There are two main types of E6000 glue: one formulated for jewelry and beads and another designed for more robust applications, such as glass and outdoor projects (Hometalk). Understanding the specific type of E6000 glue is crucial for achieving the best results in your projects.

| Type | Application | Features |

|---|---|---|

| E6000 Jewelry & Bead | Jewelry, Beads, Gemstones | Precision tip, Clear finish |

| E6000 Industrial | Glass, Metal, Wood, Ceramics | Strong bond, Flexible, Waterproof |

The choice between these types depends on the specific requirements of your project. The jewelry and bead variant is ideal for delicate works, while the industrial version is better suited for heavy-duty tasks.

Success Stories with E6000 Glue

Numerous projects have demonstrated the effectiveness of E6000 glue, underscoring its reputation as a reliable adhesive. Here are some success stories that showcase its versatility:

- Reassembling a Bong: Users successfully utilized E6000 to securely reassemble glass components of a bong. The bond proved to be strong and durable.

- Hanging a Rearview Mirror: E6000 was used to attach a rearview mirror, providing a reliable hold without any issues.

- Gluing a Bearing to a Glass Table: In a project that required bonding metal to glass, E6000 glue effectively adhered a bearing to a glass table.

- Mounting Sights on a Pellet Rifle: E6000’s strong adhesive properties were also put to the test in more tactical applications, such as mounting sights on a pellet rifle.

These examples illustrate the diverse range of successful applications for E6000 glue, making it a go-to choice for many DIY enthusiasts and professionals alike.

For those interested in exploring alternatives and comparing different adhesives, you can check out our articles on e6000 vs. gorilla glue and how to use e6000 glue on fabric. These resources provide valuable insights into selecting the best adhesive for your specific needs.

Specialized Glass Glue

For various glass bonding projects, different types of adhesives offer unique benefits and cater to different requirements. Aleene’s line of specialized adhesives is particularly renowned for their effectiveness on glass. Below, we explore three types: Aleene’s Glitter Coat Adhesive, Aleene’s The Ultimate Multi-Surface Adhesive, and Aleene’s Glass & Bead Adhesive.

Aleene’s Glitter Coat Adhesive

Aleene’s Glitter Coat Adhesive is specially designed for projects involving glass and glitter. This adhesive dries ultra-clear and provides a permanent, strong bond, making it ideal for a variety of creative applications such as ornaments, glass luminaries, or wine glasses.

Application Process:

- Apply the adhesive to the inside and/or outside of the glass item.

- Sprinkle glitter while the adhesive is still wet.

- Let it dry completely.

This process results in a decorative and sparkling finish that adheres firmly to the glass.

| Attribute | Value |

|---|---|

| Drying Time | Clear |

| Bond Type | Permanent |

| Application Type | Inside/Outside Glass |

For more DIY tips on using glass glue, see our article on how to use e6000 glue on glass.

Aleene’s The Ultimate Multi-Surface Adhesive

Aleene’s The Ultimate Multi-Surface Adhesive is known for its super-strong holding capability across various surfaces. It is particularly beneficial for gluing glass to metal, offering a reliable and durable bond. Additionally, it works effectively on fabric, making it versatile for different crafting needs.

Application Process for Glass-to-Metal:

- Apply a thin coat of the adhesive to both the glass and the metal surfaces.

- Allow it to set for about 2 minutes.

- Press the items together and allow them to dry.

Application Process for Glass-to-Fabric:

- Apply the adhesive to the glass and fabric surfaces.

- Press them together and let dry.

| Attribute | Value |

|---|---|

| Drying Time | Clear and fast |

| Bond Type | Industrial-strength |

| Surfaces | Metal, Fabric |

For additional information, you can see comparisons and alternatives in our articles like e6000 vs. gorilla glue and how to use e6000 glue on fabric.

Aleene’s Glass & Bead Adhesive

Aleene’s Glass & Bead Adhesive is tailored for glass-on-glass bonding. It features a quick-setting capability and a thick, gel formula, making it perfect for sleek and smooth surfaces like glass. This industrial-strength adhesive forms a permanent bond, ensuring that glass items remain securely affixed.

Application Process:

- Apply the adhesive generously to one glass surface.

- Press the glass pieces together.

- Allow it to set quickly to form a strong bond.

| Attribute | Value |

|---|---|

| Setting Time | Quick |

| Bond Type | Permanent |

| Formula | Thick gel |

For more tips on securing a sturdy bond with different adhesives, you might be interested in articles such as does jb weld work on glass and how to make e6000 glue dry faster.

Aleene’s range of specialized glues offers excellent solutions for diverse glass projects. Whether embellishing glass items with glitter, bonding glass to metal, or securing glass-on-glass pieces, choosing the right adhesive is crucial for achieving a long-lasting bond.

Best Practices for Glass Bonding

Effective glass bonding requires careful consideration of several factors. In this section, we delve into the essential best practices to ensure a strong and lasting bond.

Proper Surface Preparation

Preparing the glass surface is a critical step in achieving a durable bond. Any contaminants on the surface can prevent the adhesive from adhering properly. Follow these steps for optimal surface preparation:

- Clean the Glass: Use 99% isopropyl alcohol to thoroughly clean the glass. Ensure all residues, dirt, and oils are removed. Allow the glass to dry completely before applying the adhesive.

- Degrease the Surface: For extra assurance, degrease the surface to eliminate any remaining oils or contaminants.

- Roughen the Surface: For stronger adhesion, lightly sand or roughen the glass surface. This increases the surface area and helps the adhesive to bond more effectively.

- Apply a Primer: In some cases, applying a primer can enhance adhesion, especially when dealing with challenging glass types.

Selecting the Right Adhesive

Choosing the correct adhesive tailored to glass is paramount. Consider the following factors to ensure you select the most appropriate adhesive for your project:

- Viscosity: Adhesives with suitable viscosity (thickness) ensure they adequately cover the bonding surface without dripping.

- Appearance: Opt for clear adhesives to maintain the aesthetic quality of the glass.

- Flexibility: Adhesives should accommodate the expansion and contraction of glass due to temperature changes.

- Thermal Stability: Thermal stability ensures that the adhesive can endure temperature variations without losing its bond strength.

Selecting a UV curable adhesive designed for glass can be beneficial due to its quick curing time and strong bond.

| Adhesive Type | Key Characteristics | Suitable for Glass? |

|---|---|---|

| E6000 | Flexible, industrial strength | Yes |

| UV Curable | Quick curing, clear | Yes |

| Epoxy | High strength, thermal stability | Sometimes |

| Super Glue | Quick bond, rigid | Sometimes |

For more comparisons, visit our article on e6000 vs. gorilla glue.

UV Curable Adhesive for Glass

UV curable adhesives offer exceptional bonding strength and clarity when used on glass surfaces. Here’s how to use them effectively:

- Surface Preparation: As with all adhesives, ensure the glass surfaces are clean and free from contaminants. Follow the steps outlined in the proper surface preparation section.

- Applying UV Cure Adhesive: Apply a thin, even layer of UV curable adhesive to the glass. Ensure complete and even coverage to prevent weak spots in the bond (LinkedIn).

- Curing the Adhesive: Use a UV light source to cure the adhesive. The intensity of the UV light and the thickness of the adhesive layer can affect curing time. Some adhesives cure in seconds under ideal conditions, so always check the label for specific curing instructions (LinkedIn).

It’s also essential to frequently inspect for gaps or uneven spots in the bonded line and to conduct tests to ensure the bond is strong and reliable.

For more insights, visit our articles on jb weld vs. gorilla glue and does jb weld work on glass.

By following these best practices, you can achieve a strong and durable bond for all your glass projects.

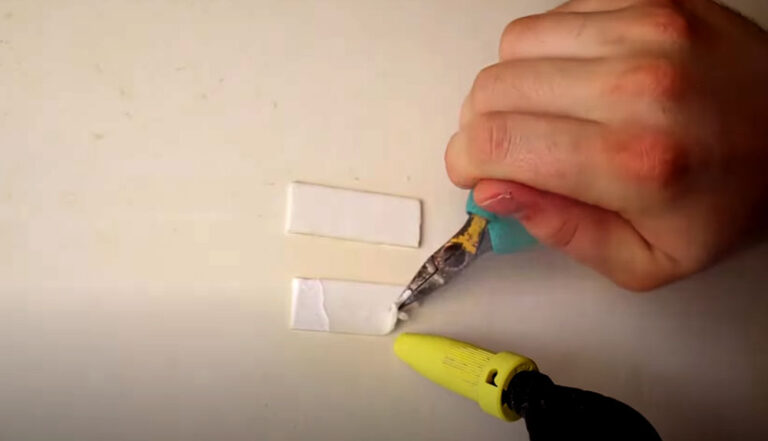

Application Techniques

Applying UV Cure Adhesive

Applying UV Cure Adhesive correctly is crucial for achieving a strong bond. The first step is ensuring that the glass surfaces are properly cleaned and prepped. Thoroughly clean and degrease the glass, and if necessary, sand or roughen the surface to enhance adhesion. Some adhesives might also benefit from a primer, so consulting the product’s technical datasheet is advised.

Next, apply the adhesive evenly over the bonding area using a suitable dispensing tool. Make sure the adhesive wicks into the entire bond area without entrapping air. Position the UV light source correctly, ensuring the wavelength matches the glued glass’s specific requirements (Permabond). Different UV adhesives may have varying curing times.

| Factors Affecting Curing Time | Details |

|---|---|

| Intensity of UV Light | Higher intensity cures faster |

| Thickness of Adhesive Layer | Thicker layers take longer |

| Proper Wavelength | Mismatched wavelengths delay curing |

Ensuring Proper Coverage

Proper coverage of the adhesive is essential for a durable bond. To ensure adequate coverage, practice the application before the actual use. This practice run should include adjusting the dispensing equipment and verifying that the adhesive covers the entire bond area without leaving gaps or air bubbles (Permabond).

Even and thorough coverage can be achieved by using the right tools and techniques. Use a spreader or brush if necessary to ensure the adhesive is uniformly distributed across the bonding surface.

| Steps for Ensuring Proper Coverage | Description |

|---|---|

| Surface Preparation | Clean, degrease, and roughen as needed |

| Practice Application | Adjust equipment settings |

| Even Distribution | Use tools like spreaders to ensure uniform application |

Testing the Bond

Testing the bond strength is a critical step in ensuring the durability and longevity of the adhesive. After the adhesive has fully cured, perform a test run to assess the bond’s strength, environmental resistance, and temperature resilience. Implementing this test helps in identifying any potential weaknesses in the bond before proceeding with the final application (Permabond).

Different scenarios and conditions can affect the bond’s strength, so it’s important to test under conditions similar to the intended use. For example, if the item will experience temperature fluctuations, ensure the testing process includes similar conditions.

| Testing Parameters | Details |

|---|---|

| Bond Strength | Test the adhesion force |

| Environmental Resistance | Check resistance to moisture and temperature |

| Durability | Assess long-term stability and integrity |

By following these application techniques, you can achieve a perfect bond using UV Cure Adhesive on glass. For comparison with other types of adhesives, see our articles on rapid fuse vs. super glue, JB Weld vs. Gorilla Glue, and how to remove E6000 glue.

Safety Measures

When using E6000 glue on glass, ensuring safety should be a priority. This section outlines the necessary protective gear, ventilation needs, and safe handling practices for effective and safe use of E6000 glue.

Protective Gear

Protective gear is essential to safeguard against potential hazards while using E6000 glue. Users should wear:

- Gloves: To protect skin from the adhesive and any chemicals.

- Safety glasses: To shield eyes from accidental splashes and airborne particles.

- Protective clothing: To minimize skin exposure and prevent adhesive contact with clothes.

Ventilation

Good ventilation is crucial when working with E6000 glue since it emits fumes that can be harmful when inhaled. Steps to achieve proper ventilation:

- Work in a well-ventilated area, preferably near an open window or with a fan to promote air circulation.

- Consider using a fume extractor if working in a more confined space to actively remove fumes from the workspace.

Safe Handling Practices

Adhering to safe handling practices ensures both user safety and optimal bonding results. Essential practices:

- Surface Preparation: Properly clean and dry surfaces with 99% isopropyl alcohol to remove contaminants before applying the adhesive (Permabond).

- Application: Apply the glue in a well-controlled manner to avoid excessive use and potential spillage.

- Storage: Keep E6000 glue in a cool, dry place away from direct sunlight and out of reach of children.

For more information on handling adhesives and their alternatives, see our articles on wood glue vs. white glue and rubber cement vs. super glue.

Using these safety measures will help ensure safe and effective use of E6000 glue for glass projects. For more tips on using E6000 glue, visit how to make e6000 glue dry faster and how to remove e6000 glue.