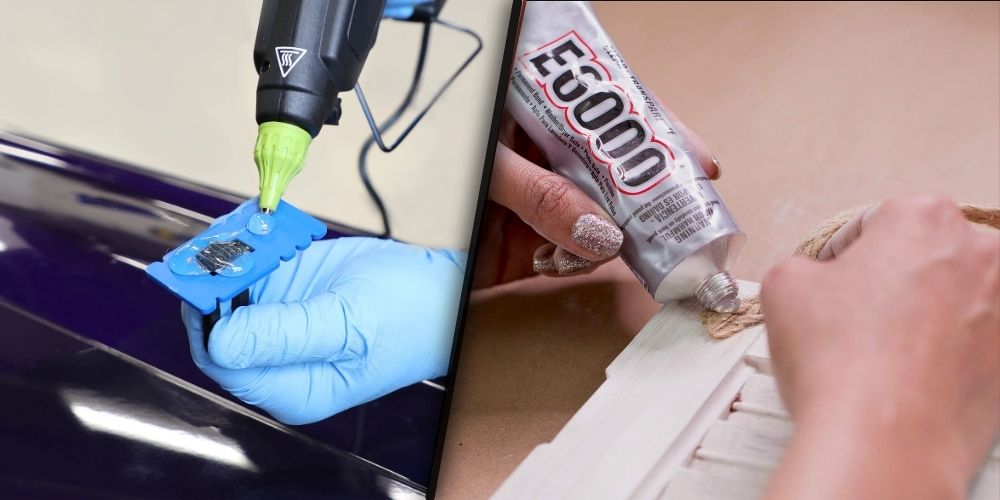

Hot Glue vs E6000: Complete Comparison Guide

Hot Glue Overview

Definition and Uses

Hot glue, also known as hot-melt adhesive, is a versatile bonding agent used primarily in crafts, woodworking, and various assembly processes. The adhesive is a thermoplastic resin that melts when heated in a glue gun. Upon application, it cools and hardens rapidly, creating a strong bond that can be used on materials like wood, felt, cardboard, and glass. One notable advantage of hot glue is that its bonds can be reheated and adjusted, making it ideal for temporary bonds during complex assembly projects (Family Handyman).

Strengths and Weaknesses

Hot glue possesses several strengths that make it a popular choice across various applications. However, it also comes with certain limitations.

Strengths:

- Quick Setting Time: Hot glue sets and cures rapidly, making it suitable for projects requiring immediate bonding.

- Flexibility and Strength: The polymers in hot-melt adhesives impart flexibility, strength, and resistance to impact and shear forces (IQS Directory).

- Heat Resistance: Hot glue remains effective at various temperatures, from low to moderately high heat.

- Reusability: Bonds can be reactivated and adjusted by reheating the glue, offering the advantage of temporary bonding options.

- Thickness Maintenance: Hot glue maintains its thickness upon drying, which is crucial for applications like woodworking and commercial projects (Hotmelt.com).

Weaknesses:

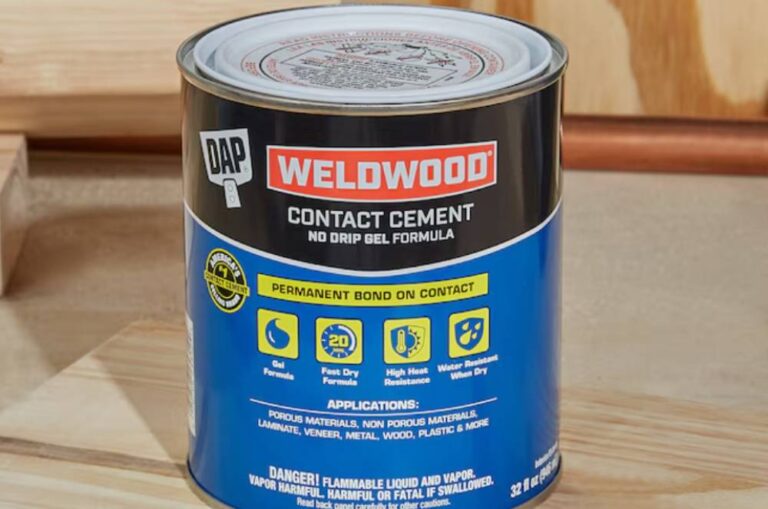

- Limited Durability: While strong, the bond created by hot glue is not as durable as some other adhesives like E6000 or contact cement.

- Temperature Sensitivity: Extremely high temperatures can weaken the bond, leading to potential failure.

- Surface Compatibility: Hot glue may not adhere well to all surfaces, especially those that are non-porous or very smooth.

- Chemical Composition: The polymers in hot glue can degrade over time despite the presence of antioxidants such as aromatic amines and phenols (IQS Directory).

| Property | Hot Glue |

|---|---|

| Setting Time | Fast |

| Temperature Resistance | Moderate |

| Durability | Moderate to low |

| Flexibility | High |

| Surface Compatibility | Limited (best on porous materials) |

| Reusability | High (can be reheated and adjusted) |

| Chemical Stability | Moderate (affected by degradation over time) |

For those comparing hot glue with E6000 or other adhesives, consider reading more on hot glue vs. wood glue and details on liquid nails vs. e6000.

E6000 Adhesive Explained

E6000 adhesive is a popular and versatile adhesive known for its exceptional bonding strength and flexibility. It is favored by many for its ability to bond a wide range of materials, making it an essential tool in various applications.

Characteristics and Applications

E6000 is a high-performance, industrial-grade adhesive designed for multiple uses. Its key characteristics include:

- Strong Bond: E6000 forms a powerful bond that can withstand various stresses and strains.

- Flexibility: Once cured, the adhesive remains flexible, which is beneficial for materials that will experience movement or vibrations.

- Waterproof: E6000 is resistant to water, making it suitable for both indoor and outdoor applications. To know more about waterproof adhesives, visit is contact cement waterproof.

- Chemical Resistance: It is resistant to certain chemicals, such as dilute acids and dilute caustics, enhancing its durability.

- Versatility: It can bond a wide range of materials, including metal, glass, ceramic, wood, and certain plastics.

Applications of E6000 include:

- Craft Projects: Ideal for jewelry making, embellishing, and other craft projects where a strong and flexible bond is required.

- Home Repairs: Useful for fixing broken items around the house, such as ceramics, metal fixtures, and glass items.

- Industrial Use: Employed in various industrial applications, including automotive repairs, due to its robust bonding properties.

For more on choosing the right adhesive, check out our comparison articles like 527 glue vs e6000 and goop glue vs e6000.

Considerations and Recommendations

When using E6000 adhesive, there are several important considerations to keep in mind:

- Curing Time: E6000 requires a longer curing time compared to instant adhesives like hot glue. It typically takes 24 to 72 hours to fully cure, depending on the ambient conditions and the thickness of the adhesive layer.

- Ventilation: E6000 emits strong fumes during application and curing. It is recommended to use this adhesive in a well-ventilated area to avoid inhaling the fumes.

- Surface Preparation: For best results, surfaces to be bonded should be clean, dry, and free of grease or oil. Lightly roughening the surface can improve adhesion.

- Temperature Sensitivity: While E6000 is relatively durable, extreme temperatures (both hot and cold) can affect its performance. It is important to consider the operating conditions of the environment where the adhesive will be used.

Here is a table comparing the curing time and temperature resistance of E6000 with hot glue:

| Adhesive | Curing Time | Temperature Resistance |

|---|---|---|

| Hot Glue | Instant (Cool down in seconds) | -20°F to 140°F |

| E6000 | 24 to 72 hours | -40°F to 180°F |

Understanding these considerations can help in making an informed decision about when and where to use E6000. Also, always refer to the manufacturer’s instructions for specific application guidelines and safety precautions.

For alternative adhesives and their comparisons, you might find our articles liquid fusion glue vs. e6000 and liquid nails vs. e6000 informative. Additionally, for plastic bonding, explore ca glue vs. wood glue.

Hot Glue vs. E6000

Examining the strengths and weaknesses of hot glue versus E6000 adhesive is essential for determining which is best suited for specific applications. Below, we compare their adhesion, versatility, and durability.

Adhesion Comparison

When it comes to adhesion, hot glue and E6000 exhibit distinct characteristics which make them suitable for various tasks.

Hot Glue:

Hot glue, also known as hot-melt glue, is a thermoplastic resin that bonds instantly when it cools and solidifies (Family Handyman). While it offers strong initial hold, the bond is not permanent and can be remelted and repositioned by reheating. This feature is beneficial for temporary bonds in complex projects.

E6000:

E6000 adhesive is an industrial-strength glue known for its robust bond, which remains flexible and weather-resistant. It is highly effective on various materials, including metal, glass, ceramic, and most plastics. Unlike hot glue, E6000 forms a permanent bond that withstands environmental factors like moisture and temperature changes (Hotmelt.com).

| Adhesion Factor | Hot Glue | E6000 |

|---|---|---|

| Initial Bond Strength | High | Medium |

| Permanent Bond | No | Yes |

| Re-meltable | Yes | No |

| Environmental Resistance | Low | High |

Versatility and Durability

The versatility and durability of an adhesive determine its range of applications and longevity of the bond.

Hot Glue:

Hot glue excels in versatility, suitable for a wide range of materials such as wood, felt, cardboard, glass, and certain plastics. It is widely used in furniture assembly, packaging, and construction. However, its bond may degrade over time, especially when exposed to extreme temperatures or moisture.

E6000:

E6000 is renowned for its durability, forming a lasting bond that resists environmental challenges. It remains flexible after curing, making it suitable for applications that require a strong yet pliable bond. This adhesive is particularly favored in demanding environments, such as outdoor settings and situations where the bond will be subjected to stress and movement (Hotmelt.com).

| Factor | Hot Glue | E6000 |

|---|---|---|

| Material Compatibility | High | High |

| Flexibility after Curing | No | Yes |

| Resistance to Moisture | Low | High |

| Longevity of Bond | Moderate | High |

For more information on adhesives and their various applications, visit our pages on liquid fusion glue vs. E6000 and construction adhesive vs. wood glue. Understanding these factors can help you make an informed decision when choosing between hot glue and E6000 adhesive for your specific needs.

Industrial Applications of Hot Glue

Hot glue, often referred to as hot-melt glue, is a thermoplastic adhesive widely used in various industrial applications due to its instant bonding capability and versatility. Let’s explore the significant roles it plays in furniture and woodworking, building and construction, and packaging and carton sealing.

Furniture and Woodworking

In the furniture and woodworking industry, hot glue is favored for its nearly instant bonding strength, which significantly speeds up production Hotmelt.com. It is effective in bonding various materials such as wood, particle board, MDF, laminate, foam, and fabrics. This feature provides flexibility and efficiency in furniture assembly processes.

| Material | Bond Strength | Bonding Time |

|---|---|---|

| Wood | High | Instant |

| Particle Board | High | Instant |

| MDF | High | Instant |

| Laminate | Medium | Instant |

| Foam | Medium | Instant |

For woodworking, specific hot melt glue sticks are formulated to offer a medium open time, allowing more time to adjust and position pieces accurately. This is essential for assembling complex projects where precise placement is necessary. Check out our comparison on hot glue vs. wood glue to learn more.

Building and Construction

Hot glue is also heavily utilized in the building and construction industry. It is applied in various applications such as flooring, carpet installation, wall tiles, door construction, and window installation Hotmelt.com. Its quick adhesion properties contribute to efficient installation processes and ensure high-quality finishes.

| Application | Bond Strength | Use Case |

|---|---|---|

| Flooring | High | Ensures quality and aesthetics |

| Carpets | High | Quick installation |

| Tiles | Medium | Vertical surface applications |

| Doors | High | Resilience to extreme temperatures |

| Windows | High | Secure installation |

Hot glue’s rapid bonding and durability are beneficial for applications requiring resilience to extreme temperatures, such as in garage doors. For a deeper dive into adhesives used in construction, explore construction adhesive vs. epoxy.

Packaging and Carton Sealing

In the packaging industry, hot glue is an excellent choice for carton sealing, pallet stabilization, and ensuring adhesion in challenging conditions. Its water resistance and shorter set time allow for more efficient packaging processes Hotmelt.com.

| Function | Efficiency |

|---|---|

| Carton Sealing | High |

| Pallet Stabilization | High |

| Resistance to Water | High |

| Set Time | Short |

The ability of hot glue to maintain continuous operations without frequent resets makes it invaluable for end-of-line packaging. For further insights on adhesives used in packaging, see our guide on liquid nails vs. e6000.

By understanding the diverse industrial applications of hot glue, professionals can select the right adhesive for their specific needs, ensuring both efficiency and durability in their projects.

Bonding Plastic Materials

When bonding plastic materials, choosing the right adhesive and knowing the proper techniques is crucial for achieving strong, durable bonds. This section delves into the specifics of bonding plastic surfaces, necessary treatments, and overcoming challenges.

Surfaces and Treatments

Different plastics have different bonding requirements. Surface treatment is often a vital step to ensure a successful bond.

| Plastic Type | Recommended Treatment | Reference |

|---|---|---|

| ABS | Solvents like MEK or dichloromethane | 3M |

| PET | Physical/Chemical activation | 3M |

| PA (Polyamide) | Special pre-treatment or reactive adhesives | 3M |

| POM | Flame treatment, primer etching, corona, or plasma | 3M |

| PS (Polystyrene) | Solvent, depends on second material | 3M |

Specific Plastic Bonding Techniques

Different techniques are essential depending on the type of plastic and the desired bond strength.

-

ABS: ABS is often used in automotive parts and electronics. Prior to bonding, cleaning the surface with solvents like methyl isobutyl ketone (MEK) or dichloromethane ensures better adhesion.

-

PET: PET is commonly found in beverage containers and packaging. Surface activation through physical (like roughening) or chemical (like primers) methods enhances adhesive performance.

-

PA (Polyamide): Known for its mechanical properties, PA is common in textiles and automotive applications. Special pre-treatments or reactive adhesives are necessary to achieve high bond strengths.

-

POM: With its excellent sliding and wear behavior, POM is utilized in machine parts. Surface treatments like flame treatment or plasma enhance bonding capabilities, though modern high-performance adhesives can sometimes eliminate the need for extensive pre-treatments.

-

PS (Polystyrene): Polystyrene is widely used in consumer products. It is easily bonded due to its solvent-soluble and polar nature, but the choice of adhesive may vary depending on the secondary material.

Challenges and Solutions

Bonding plastic presents various challenges that require appropriate solutions:

-

Surface Preparation: Plastics like ABS and PET require special surface treatments for effective bonding. Utilizing solvents such as MEK or activation methods such as roughening helps improve adhesion.

-

Choosing the Right Adhesive: Some plastics, such as PA and POM, demand special adhesives that can form strong bonds without extensive pre-treatment. High-performance adhesives or reactive formulas are suitable choices.

-

Compatibility Issues: Polystyrene (PS) is easily bonded, but the choice of adhesive depends on the other material involved. Assessing compatibility between the two substrates ensures a durable bond.

For more information on the most suitable adhesives for various materials, explore our other articles such as shoe goo vs. contact cement and liquid nails vs. e6000.