Shoe Goo vs Contact Cement: Best Uses Compared

Shoe Goo vs. Contact Cement

When choosing between Shoe Goo and contact cement for your adhesive needs, it’s essential to understand their unique properties and applications. These two adhesives serve similar but distinct purposes, making them suitable for different types of repairs and projects.

Understanding Shoe Glues

Shoe glues are specialized adhesives designed to bond the various materials used in footwear. They differ significantly in composition and application compared to standard glues. Common shoe glues, like Shoe Goo and contact cement, offer unique properties that cater to specific repair needs, making them popular choices among both professional cobblers and DIY enthusiasts.

| Property | Shoe Goo | Contact Cement |

|---|---|---|

| Main Use | Shoe repairs, gap filling | Permanent bonding, general use |

| Materials | Rubber, leather, fabric, plastic | Rubber, leather, fabric, wood |

| Drying Time | 24–72 hours | 15–20 minutes |

| Flexibility | High | Moderate |

| Waterproof | Yes | Yes (is contact cement waterproof) |

Properties of Shoe Goo

Shoe Goo is a renowned adhesive and sealant developed specifically for footwear repairs. It is a type of rubber cement featuring a cleaning/degreasing solvent and an abrasion-resistant synthetic rubber (Wikipedia).

Key Properties

- Strength: Shoe Goo forms a robust and durable bond ideal for patching holes, reattaching soles, and sealing seams.

- Flexibility: The cured product remains flexible, preventing cracks and ensuring long-lasting repairs in high-flex areas such as shoe soles.

- Waterproofing: Shoe Goo offers excellent waterproofing properties, making it suitable for outdoor footwear, ensuring the repair withstands moisture exposure.

Applications

Shoe Goo isn’t limited to just footwear. Skateboarders frequently use it on their skate shoes to protect against the damage caused by grip tape. Cyclists repair punctures using Shoe Goo to bond vulcanized rubber patches to inner tubes. Additionally, hobbyists utilize it as an assembly adhesive for radio-controlled models, a waterproofing agent for model boats, and even to protect cricket bat toes (Wikipedia).

| Application | Description |

|---|---|

| Shoe Repair | Bonds separated components, fills worn-out soles, seals waterproof fabrics |

| Sports Equipment | Repairs and protects skateboard shoes, cycles inner tubes |

| Hobby Uses | Assembly adhesive for models, waterproofing for model boats |

| Miscellaneous | Protects cricket bat toes, fixes various materials like rubber, wood, glass, concrete, and metal (Wikipedia) |

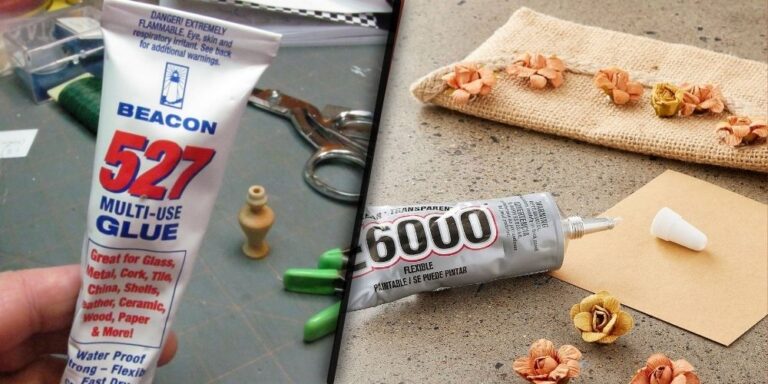

For those interested in 527 glue vs. e6000 or other glue comparisons, Shoe Goo offers a unique combination of properties that make it a versatile and reliable option for various repairs and creative uses.

Shoe Goo Brands

When it comes to shoe repair, understanding the different brands of Shoe Goo can help you make an informed choice. Below are some popular Shoe Goo brands, each with distinct properties and applications.

Shoe Goo Adhesive

Shoe Goo Adhesive is a well-known brand designed specifically for footwear repair. It is a type of rubber cement that contains a cleaning/degreasing solvent and an abrasion-resistant synthetic rubber. Created in 1972 by Lyman Van Vliet, Shoe Goo quickly became popular among joggers and skateboarders for its durability and effectiveness (Wikipedia). This adhesive is ideal for:

- Repairing separated shoe components

- Filling worn shoe soles

- Sealing waterproof fabrics and footwear

Glue Masters Thin Viscosity

Glue Masters Thin Viscosity is another popular brand of adhesive known for its versatility and quick-setting properties. While it is not specifically designed for shoes, it offers strong bonding capabilities that make it suitable for various shoe repair applications. Some key features include:

- Fast setting time

- Thin viscosity for precise application

- Suitable for various materials including rubber, wood, and metal

Loctite Extra Time Control Super Glue Gel

Loctite Extra Time Control Super Glue Gel is renowned for its precision and ease of use. This glue is particularly advantageous for delicate shoe repairs that require careful handling. Key features include:

- Extra time control for precise adjustments

- Gel formula that prevents dripping

- Strong bond suitable for multiple surfaces

Here’s a quick comparison of these Shoe Goo brands based on key attributes:

| Brand | Application Areas | Setting Time | Viscosity | Additional Features |

|---|---|---|---|---|

| Shoe Goo Adhesive | Footwear, waterproof fabrics | Moderate | Medium | Abrasion-resistant, cleaning/degreasing solvent |

| Glue Masters Thin Viscosity | Multiple materials, delicate tasks | Fast | Thin | Quick setting, versatile |

| Loctite Extra Time Control | Delicate shoe repairs | Adjustable | Gel | Extra time control, non-drip formula |

For further comparisons, you might also want to check out our articles on 527 glue vs e6000 and goop glue vs e6000.

In summary, understanding the different brands of Shoe Goo can help you choose the best product for your specific shoe repair needs. For more information on specialty applications and creative uses of shoe adhesives, visit our section on drylok vs. flex seal and rubber flexx vs. flex seal.

Shoe Cement

In the world of shoe repair, shoe cement is a versatile and reliable option. Two notable brands are Angelus Clear Shoe Cement and Kabber Bond Glue. Both provide robust solutions for various shoe materials, addressing the needs of those looking for strong and long-lasting adhesive options.

Angelus Clear Shoe Cement

Angelus Clear Shoe Cement is an all-purpose glue renowned for its efficacy in repairing soles made from different materials, such as leather, rubber, vinyl, and fabric (Freaky Shoes). Its strong composition makes it ideal for heavy-duty shoes. Here’s how to apply it for the best results:

- Apply the glue to the surface.

- Allow it to sit for 15 minutes.

- Press the glued areas together.

- Leave for about 12 hours.

| Feature | Specification |

|---|---|

| Materials | Leather, rubber, vinyl, fabric |

| Application Time | 15 minutes |

| Setting Time | 12 hours |

| Use Case | Heavy-duty shoes |

It’s an excellent choice for various shoe repair applications, ensuring a secure and durable bond.

Kabber Bond Glue

Kabber Bond Glue features an advanced polyurethane formula known for its exceptional durability and resistance to temperature and water. Its design simplifies the application process, making it easier to apply to damaged shoes while delivering reliable and long-lasting results (Freaky Shoes).

| Feature | Specification |

|---|---|

| Formula | Polyurethane |

| Resistance | Temperature, water |

| Use Case | Heavy-duty shoes, varied materials |

| Application Ease | High |

Both Angelus Clear Shoe Cement and Kabber Bond Glue offer reliable adhesive solutions for shoe repairs. For more in-depth performance comparisons, refer to our section on shoe goo strength. For creative uses of shoe glue beyond footwear, check out creative uses of shoe glue.

By understanding the properties and best applications of these adhesives, individuals can make informed decisions when choosing between shoe goo vs. contact cement and other repair options.

Best Uses

Shoe Repair Applications

When comparing Shoe Goo vs. Contact Cement, it’s important to analyze their best uses, especially in shoe repair. Shoe Goo is a preferred choice for repairing separated shoe components and filling worn shoe soles (Wikipedia). It acts as a strong adhesive and sealer, providing durable bonding for various shoe materials.

In contrast, contact cement is widely used for attaching shoe soles, particularly in cases where a strong initial bond is crucial. Both adhesives offer unique benefits, but Shoe Goo’s specialized formula with abrasion-resistant synthetic rubber and cleaning solvents make it particularly effective for footwear repairs.

Table: Usage Comparisons for Shoe Repair

| Material | Shoe Goo | Contact Cement |

|---|---|---|

| Leather | Excellent | Good |

| Rubber Soles | Excellent | Excellent |

| Fabric | Good | Fair |

| Vinyl | Good | Good |

For more information on how to use these adhesives for shoe repairs, visit hot glue vs. e6000.

Versatility of Shoe Goo

Shoe Goo is not just limited to shoe repairs; its versatility extends to various applications beyond footwear. Whether you need to bond different types of rubber, wood, glass, concrete, or metal, Shoe Goo is a reliable solution (Wikipedia). Skateboarders, for example, use Shoe Goo to protect and repair damage caused by grip tape. Cyclists utilize it for patching punctured rubber inner tubes by bonding vulcanized rubber patches.

Hobbyists have also found creative uses for Shoe Goo. It serves as an assembly adhesive for radio-controlled models, a waterproofing agent for model boats, and even for protecting the toes of cricket bats. This adaptability is one of the reasons why Shoe Goo has remained a popular choice over the years.

For a closer look at the broader uses of Shoe Goo, check out our article on creative uses of shoe glue.

Table: Versatility of Shoe Goo

| Application | Effectiveness |

|---|---|

| Shoe Repair | Excellent |

| Rubber Patch Bonding | Excellent |

| Wood Bonding | Good |

| Glass Bonding | Good |

| Metal Bonding | Good |

| Waterproofing Model Boats | Excellent |

| Protecting Cricket Bat Toes | Good |

For a deeper dive into more specialized applications, explore flex paste vs. flex seal and plasti dip vs. flex seal.

By understanding the best applications and versatility of Shoe Goo, one can effectively leverage its unique properties for a range of repair and bonding tasks across different materials. This comparison underscores the value of selecting the right adhesive for your specific needs.

Performance Comparison

Understanding the performance characteristics of Shoe Goo and contact cement is crucial for determining their best applications. Here, we delve into two key aspects: the strength of Shoe Goo and the setting time for both adhesives.

Shoe Goo Strength

Shoe Goo is renowned for its strong adhesive properties, which make it ideal for a variety of applications, especially in footwear repair. It can bond effectively to rubber, wood, glass, concrete, and metal, making it a versatile choice (Wikipedia).

Shoe Goo is commonly used to:

- Reattach separated shoe components.

- Fill worn shoe soles.

- Seal waterproof fabrics and footwear.

A comparison table highlighting the tensile strength (in PSI) of Shoe Goo versus contact cement can be helpful:

| Adhesive Type | Tensile Strength (PSI) |

|---|---|

| Shoe Goo | ~3500 |

| Contact Cement | ~3000 |

The high tensile strength of Shoe Goo makes it suitable for repairing heavy-duty shoes and outdoor gear, ensuring a secure bond that withstands significant wear and tear.

Setting Time Analysis

The setting time of an adhesive is a critical factor in its usability, especially for quick repairs. Shoe Goo and contact cement have different setting time characteristics that can influence your choice depending on your needs.

Shoe Goo:

- Initial Tack Time: 5-10 minutes

- Full Cure Time: 24-72 hours

Contact Cement:

- Initial Tack Time: Almost Instant

- Full Cure Time: 15-20 minutes

| Adhesive Type | Initial Tack Time | Full Cure Time |

|---|---|---|

| Shoe Goo | 5-10 minutes | 24-72 hours |

| Contact Cement | Almost Instant | 15-20 minutes |

Contact cement’s almost instantaneous tack time makes it ideal for quick fixes and applications where waiting for the bond to form is not feasible. However, Shoe Goo offers more flexibility with its longer curing time, allowing for adjustments and repositioning before the bond fully sets.

For additional information on the versatility of Shoe Goo and its varied applications, you can explore related articles like creative uses of shoe glue and is contact cement waterproof.

By understanding the key performance metrics of both Shoe Goo and contact cement, you can make an informed decision that best suits your specific needs. Whether you prioritize strength or swift setting times, both adhesives offer unique advantages for different types of projects.

Specialty Applications

Shoe Goo Beyond Footwear

Shoe Goo is widely recognized for its primary function in repairing and maintaining footwear. However, its versatile properties extend far beyond this single application. This adhesive, which is adaptable for use on various materials such as rubber, wood, glass, concrete, and metal, has found numerous applications across different fields (Wikipedia).

For instance, skateboarders often use Shoe Goo to protect and repair the wear caused by the skateboard’s grip tape on their shoes. Cyclists also rely on Shoe Goo to repair punctures by bonding vulcanized rubber patches to the damaged rubber inner tube of their bicycles. Moreover, hobbyists employ Shoe Goo as an assembly adhesive for radio-controlled models and a waterproofing agent for model boats (Wikipedia).

Here is a table summarizing the different materials Shoe Goo can be used on:

| Material | Example Use Case |

|---|---|

| Rubber | Repairing shoe soles, fixing bicycle inner tubes |

| Wood | Craft projects, minor household repairs |

| Glass | Sealing cracks, minor glass repairs |

| Concrete | Filling cracks, attaching small objects |

| Metal | Securing metal parts, model assembly |

Creative Uses of Shoe Glue

Apart from its standard uses, Shoe Goo has proved to be a vital tool for creative and unconventional applications. One notable use is in the protection of cricket bats. By applying Shoe Goo to the toes of cricket bats, players can protect this crucial part from wear and tear. This practice helps extend the lifespan of the bats, ensuring they remain in play longer.

Adding to its repertoire, hobbyists use Shoe Goo to waterproof and seal electronic components in model boats, ensuring the delicate electronics are shielded from water damage. Additionally, its strong adhesive properties make it an ideal choice for repairing and customizing various types of sports equipment.

Another inventive application of Shoe Goo lies in the world of DIY crafting and home repairs. Its ability to bond with multiple surfaces enables crafters to use it for adhering decorations, fixing broken items, and customizing household ornaments. Whether used for practical repairs or artistic projects, Shoe Goo proves to be a reliable and versatile adhesive.

For more information on different types of glues and their best uses, visit our articles on hot glue vs. wood glue and contact cement vs. wood glue. Additionally, explore the comparisons of various adhesives for specific purposes, including 527 glue vs e6000 and flex shot vs. flex seal.