Is Contact Cement Waterproof? Expert Guide

Understanding Contact Cement

Contact cement is a versatile adhesive known for its strong bonding capabilities. It is widely used in various applications, from woodworking to laminating surfaces.

Bonding Process Overview

Contact cement provides an instant permanent bond when brought into firm contact after being applied to two mating surfaces and allowed to dry (CP Adhesives). The process involves coating the surfaces to be adhered together with the adhesive and allowing it to dry until it is tacky. Once the surfaces are brought together, they form an immediate bond that becomes permanent.

Key Steps:

- Application: Apply a uniform layer of contact cement on both surfaces.

- Drying: Allow the adhesive to dry until it becomes tacky but not wet.

- Bonding: Bring the surfaces together firmly.

Surfaces Suitable for Contact Cement

Contact cement can bond a variety of substrates, making it a popular choice for multiple applications. Each surface has its unique characteristics, but contact cement adapts well to these differences.

Suitable Surfaces:

- Wood: Widely used for bonding wood veneers and laminates.

- Leather: Ideal for repairs and crafts involving leather materials.

- Metal: Can be used for bonding metal surfaces, although surface preparation is critical.

- Plastic: Commonly used for attaching plastic laminates to various substrates.

- Rubber: Effective for bonding rubber materials in different applications.

| Surface | Example Applications |

|---|---|

| Wood | Veneers, wood laminates |

| Plastic | Laminate countertops, plastic sheets |

| Metal | Metal sheets, decorative metal panels |

| Leather | Leather repairs, crafts |

| Rubber | Rubber gaskets, rubber mats |

For best results, it is crucial to choose the right type of contact cement designed for the specific project, such as flooring adhesive for floors and laminate adhesive for countertops (LOCTITE). For more information on selecting suitable adhesives, you can explore contact cement vs. wood glue for comparative insights.

Understanding the proper application process and suitability of surfaces can significantly improve the performance of contact cement. For further details, you might want to check out our articles on shoe goo vs. contact cement and construction adhesive vs. wood glue.

Factors Affecting Drying Time

The drying time of contact cement is influenced by various factors, primarily temperature and humidity. Understanding these influences can help achieve optimal adhesive performance and ensure successful bonding.

Influence of Temperature

Temperature plays a crucial role in determining the drying time of contact adhesives. At lower temperatures, the drying process slows down, while higher temperatures accelerate the drying time (CP Adhesives). This correlation is important to consider when working in different environmental conditions.

| Temperature | Expected Drying Time |

|---|---|

| 40°F (4°C) | 60-90 minutes |

| 60°F (16°C) | 30-45 minutes |

| 80°F (27°C) | 15-20 minutes |

| 100°F (38°C) | 5-10 minutes |

These figures illustrate how significant temperature variations impact the drying time of contact cement. For example, when working in colder environments, patience is required to allow adequate drying.

Impact of Humidity

Humidity is another critical factor affecting the drying time of contact cement. Low humidity levels accelerate the drying process, while high humidity levels can slow it down significantly (CP Adhesives). Understanding humidity levels is essential for planning and executing bonding projects efficiently.

| Humidity Level | Expected Drying Time |

|---|---|

| 20% | 15-20 minutes |

| 40% | 30-40 minutes |

| 60% | 45-60 minutes |

| 80% | 60-90 minutes |

When working in environments with high humidity, additional drying time must be factored into the project timeline. Humidity impacts the efficiency of the adhesive, making it crucial to consider indoor versus outdoor work and seasonal changes.

Understanding how temperature and humidity affect the drying time of contact cement can lead to more effective use of this adhesive. For additional information on how to enhance the performance of contact cement, visit our article on contact cement vs wood glue and explore more resources like structural adhesive vs. welding.

Choosing the Right Contact Cement

Selecting the appropriate contact cement for your project is essential to ensure strong, lasting bonds. Two critical factors to consider are the solid percentage of the adhesive and the importance of using recommended thinners.

Solid Percentage Consideration

Contact adhesives with a higher solid percentage generally contain more usable adhesive per gallon. The solids in the adhesive represent the actual bonding agent, while the solvent is primarily a carrier to aid in application. A higher solid percentage means more adhesive remains on the surfaces being bonded after the solvent evaporates, resulting in a stronger bond (CP Adhesives).

| Adhesive Type | Solid Percentage | Usable Adhesive per Gallon |

|---|---|---|

| Standard Contact Cement | 70% | Moderate |

| High-Solid Contact Cement | 90% | High |

| Low-Solid Contact Cement | 50% | Low |

Choosing a high-solid contact cement can be especially beneficial when working on projects that require a reinforced bond. For instance, the Weldwood Original Contact Cement is known for its high solid content, providing strong adhesion on various surfaces.

Importance of Recommended Thinners

Thinners play a crucial role in the application and performance of contact cement. Using the manufacturer-recommended thinners ensures the adhesive performs as intended. Thinners help to achieve the right consistency for application and promote even spreading, leading to optimal bond strength.

Certain contact cements, like those used for delicate materials, may require specific thinners to prevent damage. For example, non-flammable options like the Chem-Set 205M Red and Clear Non-Flammable Contact Adhesives (Chemical Concepts) may need particular thinners to maintain their non-flammability and bonding efficiency.

| Contact Cement | Recommended Thinner | Importance |

|---|---|---|

| Neoprene Rubber Adhesive | Organic Solvents | Maintaining strong, flexible bonds |

| Non-Flammable Adhesive | Specific Non-Flammable Thinners | Safety and performance |

Using inappropriate thinners can compromise the adhesive’s strength and lead to weaker bonds. Always refer to the product specifications and guidelines to determine the right thinner for your chosen contact cement.

By paying attention to solid percentage and using the recommended thinners, you can ensure that your contact cement provides reliable and durable bonds. For further comparisons on other adhesive options, such as shoe goo vs. contact cement or liquid nails vs. e6000, explore our in-depth articles.

Applications of Contact Cement

Contact cement, known for its strong and durable bond, has a variety of applications. It is particularly useful when working with large flat surfaces or specific materials.

Versatile Project Applications

Contact cement is incredibly versatile, making it suitable for many DIY and professional projects. Here are some common uses:

- Countertops: Ensures a permanent bond for laminates used on countertops, preventing any air pockets (LOCTITE).

- Shelves and Tabletops: Ideal for attaching edging strips on shelves and tabletops.

- Cabinetry: Frequently employed in cabinetry for bonding various components.

- Furniture Repair: Used for repairing torn cushions, outdoor furniture, and even automotive seats.

| Application | Benefit |

|---|---|

| Countertops | Permanent bond without air pockets |

| Shelves/Tabletops | Secure edging strips |

| Cabinetry | Strong bond for wood components |

| Furniture | Flexible repair for cushions and seats |

Specific Material Bonding

Contact cement is designed to work with specific materials, making it ideal for various specialized applications:

- Wood: Often used to bond wooden surfaces together, such as tabletops to wood substrates.

- Metal: Suitable for metal surfaces needing a strong adhesive bond.

- Plastic: Provides reliable bonding for various types of plastics.

- Rubber: Effective for fixing items like loose shoe soles or peeling surfboard grip pads (LOCTITE).

For more information on how contact cement compares with other adhesives for different materials, visit our comparison articles like contact cement vs. wood glue, shoe goo vs. contact cement, and construction adhesive vs. epoxy.

| Material | Common Use Cases |

|---|---|

| Wood | Desktops, shelves, cabinetry |

| Metal | Metal components needing strong adhesive |

| Plastic | Various plastic items needing bonding |

| Rubber | Shoe soles, surfboard grip pads |

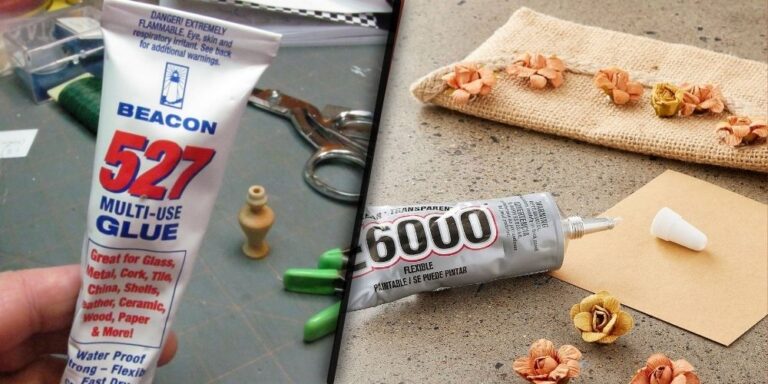

Understanding the various applications of contact cement helps in utilizing its unique properties effectively. Whether it’s a large DIY project or a small repair, choosing the right type of cement can make a significant difference in the outcome. For more detailed guidance, see articles on 527 glue vs e6000, hot glue vs. wood glue, and is jb weld waterproof.

Waterproof Properties of Contact Cement

Waterproofing Capabilities

Contact cement is a highly versatile adhesive renowned for its impressive bonding strength and durability. However, when it comes to waterproofing, the performance of contact cement varies based on its formulation. In general, contact cement offers a significant degree of water resistance, making it suitable for a range of applications where exposure to moisture is a concern.

Contact cement infused with calcium stearate, a water-resistant compound, exhibits enhanced waterproofing capabilities (PubMed Central). Calcium stearate fills internal pores and reduces permeability, effectively preventing moisture penetration. This moisture-proof mixture derived from stearic acid and limestone significantly decreases water absorption rates and contributes to the adhesive’s hydrophobic properties.

| Property | Standard Contact Cement | Calcium Stearate-Infused Contact Cement |

|---|---|---|

| Water Absorption Rate (%) | 11.8 | 2.4 |

| Contact Angle | Lower | Higher |

Water Resistance in Different Conditions

The water resistance of contact cement can vary under different environmental conditions. Factors such as temperature, humidity, and the substrate materials can impact the adhesive’s performance.

-

Temperature:

Contact cement remains effective across a broad temperature range, but extremely high or low temperatures can affect its bonding strength and water resistance. It’s essential to apply contact cement within the temperature range recommended by the manufacturer to ensure optimal performance. -

Humidity:

Humidity levels can influence the curing process of contact cement. High humidity can prolong drying times and may impact the adhesive’s initial bond strength. However, once fully cured, contact cement with water-resistant properties can withstand humid conditions effectively. -

Substrate Materials:

The type of material being bonded can also affect the water resistance of contact cement. For instance, surfaces treated with primers or sealers may exhibit enhanced water resistance. Proper surface preparation, including cleaning and priming, can significantly improve the adhesive’s performance in wet environments.

In specific applications, such as bonding large flat surfaces or materials frequently exposed to moisture, it’s crucial to choose the right type of contact cement. Different formulations, such as those designed for flooring or woodworking, offer varying degrees of water resistance. For more detailed comparisons, visit our articles on shoe goo vs. contact cement and contact cement vs wood glue.

By understanding the waterproofing capabilities and the factors affecting water resistance, one can make informed decisions when selecting contact cement for projects involving exposure to moisture. For further insights, check out our discussions on construction adhesive vs. epoxy and drylok vs. flex seal.

Enhancing Contact Cement Performance

Enhancing the performance of contact cement involves careful consideration of surface treatments and the use of additives. These methods can significantly impact the bonding quality, durability, and overall effectiveness of the adhesive.

Surface Treatment Methods

Proper surface treatment is crucial for maximizing the bonding potential of contact cement. Applying treatments like epoxy or primer to surfaces can prevent water penetration and enhance adhesion.

- Epoxy Treatment: Applying an epoxy coating to surfaces can seal pores and provide a smooth, impermeable layer, which improves the bonding surface for contact cement.

- Primer Application: Primers can prepare surfaces by creating an even base, improving adhesion, and ensuring the cement bonds more effectively.

Using treated surfaces ensures the contact cement adheres better, enhancing its water-resistant properties. For similar comparisons, explore our discussions in shoe goo vs. contact cement.

Impact of Concrete Additives

Concrete additives like calcium stearate can be used to improve the water resistance and overall performance of contact cement. Calcium stearate, derived from stearic acid and limestone, is known for its moisture-proof properties.

- Calcium Stearate: When added to concrete, it fills internal pores, reducing permeability and water absorption. The insolubility of calcium stearate makes it an excellent choice for enhancing the hydrophobicity of cement mortar, especially in non-static conditions.

| Additive | Impact on Water Absorption | Solubility Product | Contact Angle |

|---|---|---|---|

| Sand | 11.8% | – | 0.5 |

| DT3% | 2.4% | – | 1.0 |

| Calcium Stearate | Decreases | 3.61 × 10−15 | Higher than Sand |

Data courtesy of PubMed Central

However, the incorporation of calcium stearate can reduce compressive strength and potentially cause microcracks. This can be mitigated by using a lower water-to-binder ratio or adding silica fume to the mix.

| Specimen | Compressive Strength | Water Absorption | Chloride Ion Diffusion |

|---|---|---|---|

| Reference Mortar | Higher | – | Higher |

| Natural Pozzolanic + Calcium Stearate | Reduced initially, increases over time | Reduced | Lower |

Figures based on findings from PubMed Central.

For more insights into the performance of different adhesives and the impact of various additives, take a look at our articles on 527 glue vs e6000 and goop glue vs e6000.