Liquid Fusion Glue vs E6000: Best Applications

Understanding Liquid Fusion Glue

Liquid Fusion Features

Liquid Fusion Performance Adhesive stands out for its unique set of features that make it a versatile and reliable choice for various applications. This glue is recognized for its maximum holding power, successfully breaking through the limitations of traditional urethane glues. Here are the key features of Liquid Fusion:

- Clear-Drying Formula: Liquid Fusion dries clear, making it ideal for projects where visibility of adhesive residue is a concern.

- Water-Resistant: The glue is formulated to resist water, adding durability to projects exposed to moisture.

- Non-Foaming: Unlike some adhesives that expand upon drying, Liquid Fusion maintains its application shape, providing precision in gluing.

- Low Odor: The adhesive emits a minimal smell, making it user-friendly, especially in indoor or confined spaces.

| Feature | Details |

|---|---|

| Drying Property | Clear |

| Resistance | Water-resistant |

| Foaming | Non-foaming |

| Odor Level | Low |

Applications of Liquid Fusion

Liquid Fusion Adhesive is versatile and can be used across a wide range of surfaces and materials. Its clear-drying, water-resistant, non-foaming, and low-odor properties make it suitable for both practical and decorative projects. Here are some common applications:

- Craft Projects: Ideal for arts and crafts, particularly where clear drying is essential, such as scrapbooking, card making, and decoration.

- Jewelry Making: Perfect for assembling intricate pieces due to its precision application and strong holding power.

- Home Repairs: Useful for minor repairs around the house that may be exposed to moisture.

- Fabric and Textile: Effective for bonding fabrics together without foaming or creating an unpleasant odor.

- Woodworking: Suitable for woodworking projects requiring a clear and strong glue.

For comparisons and alternatives, you may want to check other adhesives like the 527 glue vs. e6000 or hot glue vs. e6000.

By understanding the features and applications of Liquid Fusion, one can make an informed decision when comparing it to other adhesives such as E6000.

Exploring E6000 Adhesive

E6000 adhesive is a versatile and widely used glue known for its strong bonding capabilities and flexibility. This section will delve into its key characteristics and suitable surfaces for application.

E6000 Characteristics

E6000 adhesive is a self-leveling, industrial-strength adhesive that is notable for its versatility and durability. This glue dries to a rubber-like consistency that remains flexible, allowing it to move with the adhered materials and prevent cracking or breaking under stress (Eclectic Products).

| Characteristic | Details |

|---|---|

| Drying Time | Starts getting tacky in approximately 2 minutes, sets in about 10 minutes, full cure between 24-72 hours |

| Temperature Range for Application | 50 °F to 90 °F (10 °C to 32 °C) |

| Temperature Resistance Once Cured | -40 °F to 180 °F (-40 °C to 82 °C) |

| UV Resistance | May be painted over for maximum UV resistance |

E6000’s flexibility makes it suitable for applications where the bonded materials may be subjected to movement or stress. It’s important to note that while it can be painted over for UV resistance, the clear version is not formulated for prolonged exposure to sunlight.

Suitable Surfaces for E6000

E6000 adhesive works well with a variety of materials, making it a popular choice for many different projects. However, it is not recommended for use on certain surfaces:

| Suitable Surfaces | Unsuitable Surfaces |

|---|---|

| – Metal | – Polystyrene |

| – Wood | – Polyethylene |

| – Glass | – Polypropylene |

| – Rubber | – Styrofoam™ |

| – Vinyl | – Paper products |

| – Fabric | |

| – Plastic (except those noted as unsuitable) |

For intricate projects involving different materials, E6000’s versatility stands out, comparable to various other adhesives like shoe goo or liquid nails.

Combining its flexibility, strong bonding power, and temperature resistance, E6000 is a reliable adhesive for many crafting and repair needs. However, always ensure you test the adhesive on a small area to confirm compatibility with your material.

For more on the comparison with different adhesives and their uses, explore our articles on hot glue vs. e6000 and goop glue vs. e6000.

Performance Comparison

Strength and Holding Power

When comparing the strength and holding power of Liquid Fusion Glue and E6000, both adhesives are known for their robust performance but have unique differences.

Liquid Fusion Glue:

- Known for its maximum holding power.

- Formulated to be water-resistant and clear-drying.

- Non-foaming and low odor, making it user-friendly.

- Ideal for a variety of surfaces and applications. (Aleene’s)

E6000:

- Renowned for its industrial strength and versatile bonding capabilities.

- Offers flexibility, ensuring that adhered materials do not crack or break under stress.

- Can be used on numerous surfaces, making it a go-to for heavy-duty projects. (Eclectic Products)

| Adhesive | Key Feature | Holding Power |

|---|---|---|

| Liquid Fusion Glue | Clear-drying, Water-resistant | High |

| E6000 | Flexible, Industrial strength | Very High |

For a deeper dive into adhesives, read more about 527 glue vs. e6000.

Drying Time and Flexibility

Drying time and flexibility are critical factors to consider when selecting an adhesive for a project.

Liquid Fusion Glue:

- Dries clear and remains flexible.

- Typically sets quickly, allowing for efficient project completion.

- Its non-foaming formula ensures a smooth finish. (Aleene’s)

E6000:

- Dries to a rubber-like consistency that remains flexible and moves with adhered material, preventing cracking under stress.

- Begins setting in about 10 minutes.

- Reaches full cure between 24 and 72 hours, although temperature and humidity can affect drying time. (Eclectic Products)

| Adhesive | Setting Time | Full Cure Time | Flexibility |

|---|---|---|---|

| Liquid Fusion Glue | Quick setting | Varies | High |

| E6000 | Starts getting tacky in 2 minutes, sets in 10 minutes | 24-72 hours | Very Flexible |

For additional insights, you may also want to explore the comparison between liquid nails vs. e6000.

In the realm of adhesives, understanding specific characteristics like strength and drying times can greatly influence project outcomes. Both Liquid Fusion Glue and E6000 offer robust solutions, catering to a wide range of applications and surfaces. For more in-depth comparisons of various adhesives, visit our articles on hot glue vs. e6000 and goop glue vs e6000.

Practical Considerations

Temperature Range for Application

When using Liquid Fusion glue and E6000 adhesive, it is essential to understand their optimal temperature ranges to ensure maximum effectiveness.

- E6000 Adhesive: Can be applied in temperatures ranging from 50 °F to 90 °F (10 °C to 32 °C) and can withstand temperatures between -40 °F and 180 °F (-40 °C and 82 °C) once cured (Eclectic Products).

The following table summarizes the temperature ranges for E6000:

| Adhesive | Application Temperature Range | Cured Temperature Range |

|---|---|---|

| E6000 | 50 °F to 90 °F (10 °C to 32 °C) | -40 °F to 180 °F (-40 °C to 82 °C) |

Liquid Fusion glue also performs well within standard room temperatures, but specific numerical ranges are not provided. It’s always advisable to follow the manufacturer’s guidelines when working with either adhesive for best results.

Painting Over for UV Resistance

Exposure to sunlight and UV rays can compromise the integrity of certain adhesives. Understanding how to properly protect your adhesive bonds is critical for long-lasting results.

- E6000: While clear E6000 is not formulated for prolonged exposure to sunlight, it can be painted over to enhance maximum UV resistance (Eclectic Products). The use of light or UV-resistant paint can help protect the adhesive from deteriorating under sun exposure.

For more information on adhesive performance in various conditions, you might find our articles on is JB Weld waterproof and is contact cement waterproof useful.

Keep these practical considerations in mind to ensure you get the best use out of your chosen adhesive, whether it is Liquid Fusion glue or E6000. For detailed comparisons, visit our related articles such as 527 glue vs e6000, goop glue vs e6000, and liquid nails vs e6000.

Tips for Effective Usage

When it comes to using different adhesives for various applications, understanding how to handle and apply them effectively is key. Here are some tips for using Liquid Fusion Glue and E6000 adhesive.

Best Practices for Liquid Fusion

Liquid Fusion Glue is a versatile adhesive known for its strong bonding capabilities and ease of use. To achieve the best results with Liquid Fusion, follow these guidelines:

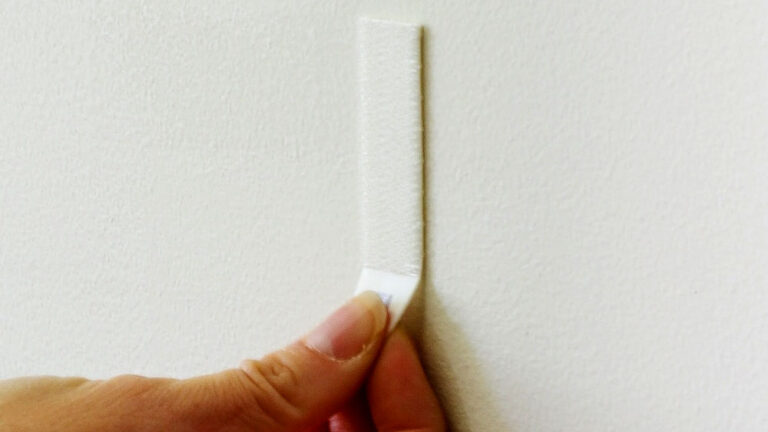

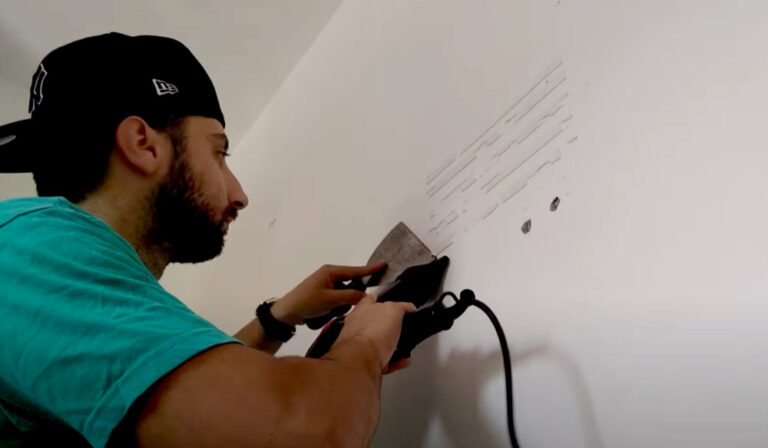

- Surface Preparation: Ensure that the surfaces to be bonded are clean, dry, and free of any debris or oils.

- Application: Apply a thin, even layer of glue to one surface. If necessary, use a brush to spread the glue evenly.

- Clamp Time: Liquid Fusion requires clamping for effective bonding. Use clamps, rubber bands, or weights to hold the pieces together while the glue sets.

- Drying Time: The glue typically sets within 2-4 hours and reaches full strength in 24 hours. Allow ample drying time before subjecting the bond to stress.

- Cleanup: Clean any excess glue with a damp cloth immediately after application, as dried glue can be difficult to remove.

Precautions and Handling for E6000

E6000 adhesive is renowned for its industrial-strength bond and versatility. However, it requires careful handling to ensure safety and effectiveness. Follow these precautions to use E6000 safely:

- Ventilation: Always use E6000 in a well-ventilated area to avoid inhaling fumes.

- Protective Gear: Wear gloves to protect your skin from the adhesive. If contact occurs, wash it off immediately.

- Temperature Range: Apply E6000 between 50 °F to 90 °F (10 °C to 32 °C). Once cured, it can withstand temperatures ranging from -40 °F to 180 °F (-40 °C to 82 °C) (Eclectic Products).

- Drying Time: E6000 starts getting tacky in about 2 minutes, sets in about 10 minutes, and fully cures in 24 to 72 hours, depending on temperature and humidity (Eclectic Products).

| Adhesive | Initial Tack Time | Full Cure Time |

|---|---|---|

| Liquid Fusion | 2-4 hours | 24 hours |

| E6000 | 2 minutes | 24-72 hours |

- UV Resistance: E6000 may be painted over for maximum UV resistance, but clear E6000 is not formulated for prolonged exposure to sunlight (Eclectic Products).

- Storage: Store in a cool, dry place to extend the shelf life of the adhesive. Make sure to tightly cap the tube after each use.

- Disposal: Dispose of any unused E6000 and empty containers in accordance with local regulations.

By following these best practices and safety precautions, users can effectively utilize Liquid Fusion Glue and E6000 adhesive for various bonding tasks. For more information on adhesive comparisons, visit our articles on 527 glue vs e6000 and goop glue vs e6000.