Solvent vs Solvent Free Adhesive: Key Differences

Understanding Adhesive Types

When it comes to adhesives, understanding the key differences between solvent-free and solvent-based options is essential. Each type has unique properties and characteristics that make them suitable for various applications.

Characteristics of Solvent-Free Adhesives

Solvent-free adhesives are formulated without the use of volatile organic compounds (VOCs) as solvents. This makes them a more environmentally friendly option, as they do not emit harmful fumes or contribute to air pollution. Their composition is generally safer for both users and the environment.

Key Characteristics of Solvent-Free Adhesives:

- Safety: Non-toxic and produce minimal fumes, reducing health hazards.

- Environmental Impact: Lower impact on air quality and reduced contribution to climate change.

- Application: Often used in indoor applications where ventilation may be limited.

- Curing Time: May have longer drying times compared to solvent-based alternatives.

These adhesives are favored in applications where health and environmental safety are priorities. To learn more about the environmental benefits of solvent-free options, visit our section on environmental and health considerations.

Properties of Solvent-Based Adhesives

Solvent-based adhesives contain VOCs that act as solvents, which can evaporate quickly and result in faster drying times. They offer superior performance in certain aspects due to the properties of the solvents they contain.

Key Properties of Solvent-Based Adhesives:

- Temperature Stability: Superior heat resistance, making them ideal for high-temperature environments.

- Chemical Resistance: Better resistance to chemicals, providing long-lasting bonds in harsh conditions.

- Weather Resistance: Enhanced durability against weather elements, making them suitable for outdoor use.

- Drying Time: Faster drying times due to the aggressive nature of the solvents.

| Property | Solvent-Free Adhesives | Solvent-Based Adhesives |

|---|---|---|

| Safety | High | Moderate |

| Environmental Impact | Low | High |

| Temperature Stability | Moderate | High |

| Chemical Resistance | Moderate | High |

| Weather Resistance | Moderate | High |

| Drying Time | Slow | Fast |

Despite their advantages, solvent-based adhesives pose significant health hazards due to the inhalation of VOCs and the flammability of the fumes they produce. They are often used in applications where performance is critical, such as in industrial settings.

For further comparison on specific adhesive types, explore our articles on 3m 4000 vs. 4200 marine adhesive and ca glue vs. epoxy.

Differences in Solvent Content

Definition of Harmful Solvents

Harmful solvents are defined as any solvents likely to cause harm to humans or the environment. These solvents are typically volatile organic compounds (VOCs) and can pose significant health risks. Regulatory bodies such as REACH and COSHH determine whether a solvent is considered harmful (Forgeway). Some common harmful solvents found in solvent-based adhesives include n-hexane, which is both flammable and neurotoxic (Kuraray Elastomer).

| Solvent | Properties | Health and Environmental Risks |

|---|---|---|

| n-Hexane | Flammable, Neurotoxic | Health Risks: Neurotoxin, Environmental Risks: Air pollutant |

| Toluene | Flammable, Acute Toxicity | Health Risks: Central nervous system depression, Environmental Risks: VOC contributor |

| Xylene | Flammable, Moderate Toxicity | Health Risks: Respiratory issues, Environmental Risks: VOC contributor |

Regulatory Standards for Adhesives

Regulatory bodies like REACH and COSHH play crucial roles in monitoring and controlling the use of harmful solvents in adhesives (Forgeway). These organizations set standards to limit the concentration of dangerous solvents in adhesive products to ensure safety for both humans and the environment.

-

REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals): A European Union regulation focusing on improving the protection of human health and the environment from risks posed by chemicals. It requires manufacturers to register and assess the safety of their chemicals.

-

COSHH (Control of Substances Hazardous to Health): A UK regulation requiring employers to control substances that can harm workers’ health. This includes enforcing strict guidelines on the use of harmful solvents in workplace environments.

Solvent-based adhesives typically contain more than 5% of these harmful solvents, categorizing them as more hazardous compared to solvent-free adhesives (Kuraray Elastomer). VOCs present in solvent-based adhesives can evaporate easily, posing health risks such as inhalation toxicity and contributing to climate change by forming smog when combined with nitrogen oxides in the atmosphere (Kuraray Elastomer).

For more information on specific product comparisons, you might find these articles useful:

Understanding the differences in solvent content is critical for choosing the right adhesive for your needs. Always consider the regulatory standards and potential health risks associated with solvent-based adhesives when making your selection.

Applications of Solvent-Free Adhesives

Solvent-free adhesives are becoming increasingly favored across various industries due to their safety benefits and superior performance. They are utilized in multiple sectors for their strong bonding capabilities and environmental advantages.

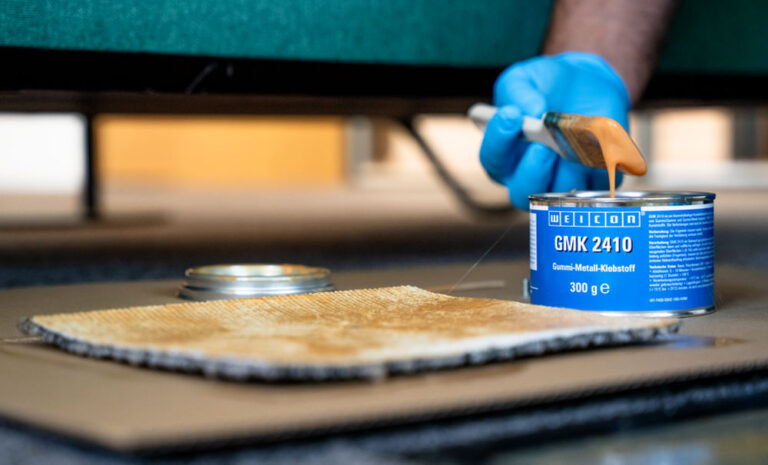

Common Uses in Various Industries

Solvent-free adhesives are particularly beneficial in applications that require attention to chemical safety and minimal emissions of harmful substances. Some common uses include:

-

Consumer Goods: In items such as diapers and food packaging where safety is paramount, solvent-free adhesives ensure that products remain free from harmful chemicals. This reduces the risk of contamination and enhances product safety. For more on comparison between adhesives, visit glue all vs. school glue.

-

Medical Applications: Solvent-free adhesives play a critical role in the production of medical devices and supplies. They help in creating secure bonds without releasing volatiles that could endanger health or interfere with sensitive materials.

-

Construction: These adhesives are used for bonding various building materials including wood, metal, and ceramics. Their flexibility and water resistance make them ideal for projects that demand durable and long-lasting adhesive solutions.

Table: Applications of Solvent-Free Adhesives

| Industry | Application | Benefits |

|---|---|---|

| Consumer Goods | Diapers, Food Packaging | Safety, Chemical-Free |

| Medical | Devices, Supplies | Non-Toxic, Secure Bonds |

| Construction | Building Materials (Wood, Metal, Ceramics) | Durability, Flexibility, Water Resistance |

For more on different adhesive uses, see metal glue vs. welding.

Advancements in Solvent-Free Technologies

The technological advancements in solvent-free adhesives represent a significant leap in both product performance and environmental sustainability. These innovations have led to several key benefits:

-

Improved Bond Strength: Modern solvent-free adhesives create stronger bonds, maintaining their strength and flexibility over time without drying out or becoming brittle (Chemique Adhesives). This makes them suitable for a wider range of materials, from plastics to metals and ceramics.

-

Enhanced Water and Chemical Resistance: These adhesives showcase excellent resistance to moisture and other chemicals, ensuring that bonds remain robust even in challenging conditions.

-

Regulatory Compliance and Safety: By eliminating volatile organic compounds (VOCs), solvent-free adhesives not only improve air quality but also ensure compliance with stringent environmental regulations. This shift promotes a safer working environment and reduces health risks for users.

-

Economic and Practical Benefits: The use of less hazardous solvents, such as water, reduces freight costs and enhances the overall economic viability of solvent-free adhesives.

Table: Advantages of Solvent-Free Technologies

| Advancement | Benefit |

|---|---|

| Improved Bond Strength | Stronger, Flexible Bonds |

| Water/Chemical Resistance | Resilient Bonds in Moist Conditions |

| Regulatory Compliance | Reduced VOCs, Safer Environment |

| Economic Advantages | Lower Freight Costs, Higher Viability |

The transition to solvent-free adhesives demonstrates a significant effort towards sustainability and enhanced product performance. For additional context on selecting adhesives for various applications, visit best adhesive for asphalt shingles.

By understanding the applications and advancements of solvent-free adhesives, individuals and businesses can make informed decisions on their adhesive choices, ensuring both performance efficiency and environmental responsibility.

Environmental and Health Considerations

Impact of Solvent-Based Adhesives

Solvent-based adhesives, while effective in creating strong initial bonds, pose significant environmental and health risks. The release of volatile organic compounds (VOCs) from these adhesives contributes to air pollution and climate change (Chemique Adhesives). VOCs are dangerous chemical gases that can cause respiratory issues, headaches, and even long-term health problems in both workers and end-users.

Additionally, solvent-based adhesives are derived from fossil fuels, further exacerbating their negative impact on the environment. These adhesives release harmful emissions, which can lead to indoor air quality issues and potential hazards in confined spaces (Chemique Adhesives). The health implications of prolonged exposure to these solvents include increased risk of chronic diseases and negative effects on the nervous system.

Benefits of Choosing Solvent-Free Options

The shift towards solvent-free adhesives represents a significant advancement in both environmental sustainability and product performance. Solvent-free adhesives eliminate the health risks associated with VOCs, ensuring better air quality and a healthier environment for workers and end-users.

Choosing solvent-free adhesives offers several benefits:

-

Health and Safety: By eliminating VOCs, solvent-free adhesives minimize health risks, reducing the chances of respiratory problems and long-term illnesses.

-

Environmental Impact: These adhesives do not release harmful emissions, contributing to a cleaner environment and reducing the overall carbon footprint.

-

Compliance and Regulations: Solvent-free formulations comply with increasingly stringent environmental regulations, making them a preferred choice for eco-conscious businesses.

-

Improved Performance: Advances in solvent-free technologies have led to adhesives that offer longer-lasting results and improved overall quality (Chemique Adhesives).

-

Temperature and Chemical Resistance: Solvent-free adhesives, though traditionally considered less resistant to temperature and chemicals, have seen significant improvements, making them more competitive with their solvent-based counterparts.

By weighing these benefits, one can make an informed decision about the best adhesive for their specific needs. For more detailed information about adhesives in other contexts, you can explore our articles on 3m 90 vs. gorilla spray adhesive, best adhesive for asphalt shingles, and aquaseal vs. shoe goo.

| Adhesive Type | VOC Emission | Health Impact | Environmental Impact | Performance |

|---|---|---|---|---|

| Solvent-Based | High | Negative | Contributes to pollution | Strong initial bond, better temperature and chemical resistance (Kuraray Elastomer) |

| Solvent-Free | None | Minimal | Reduces carbon footprint | Improved durability, eco-friendly (Chemique Adhesives) |

Choosing the right adhesive also depends on specific project needs, which might be more clearly defined in our guide on factors influencing adhesive selection.

Comparing Performance Factors

When choosing between solvent-based and solvent-free adhesives, it is crucial to consider several performance factors. This section will explore the temperature stability and resistance, as well as the bonding strength and flexibility, of each type of adhesive.

Temperature Stability and Resistance

Temperature stability and resistance are essential factors to consider, especially for applications exposed to varying temperatures. Solvent-based adhesives generally offer superior temperature stability and resistance compared to their solvent-free counterparts due to the properties of the solvents they contain. This allows them to perform well under extreme temperature conditions and ensures strong initial bonding.

| Adhesive Type | Temperature Stability | Chemical Resistance | Weather Resistance |

|---|---|---|---|

| Solvent-Based | High | High | High |

| Solvent-Free | Moderate | Moderate | Moderate |

For projects requiring high temperature stability, such as outdoor constructions or automotive applications, solvent-based adhesives are typically the preferred choice.

Bonding Strength and Flexibility

Bonding strength and flexibility are critical for ensuring the adhesive can securely hold materials together while allowing some degree of movement or flexibility. Solvent-based adhesives offer strong initial bonding, which is beneficial for applications requiring quick adhesion and handling. They are also effective on substrates with highly contaminated surfaces, providing reliable adhesion.

Solvent-free adhesives, while not always matching the initial strength of solvent-based options, have made significant advancements. For example, KURARITY™, a solvent-free, hot-melt, pressure-sensitive adhesive, offers optical clarity, high weather resistance, low viscosity, and good removability due to its all-acrylic structure (Kuraray Elastomer).

| Adhesive Type | Initial Bond Strength | Flexibility | Removability |

|---|---|---|---|

| Solvent-Based | Strong | Moderate | Low |

| Solvent-Free | Moderate | High | High |

While solvent-based adhesives typically excel in initial bonding strength, solvent-free options are improving and offer benefits in flexibility and removability, making them suitable alternatives for various applications.

For more detailed comparisons and considerations for specific projects, check out our articles on 3m 90 vs. gorilla spray adhesive and ca glue vs. epoxy.

Choosing the Right Adhesive

When selecting between solvent and solvent-free adhesives, several factors should be considered to ensure the best choice for your specific needs.

Factors Influencing the Selection

When choosing the right adhesive, it’s important to consider several factors:

-

Environmental Impact: Solvent-free adhesives produce significantly fewer volatile organic compounds (VOCs), which makes them safer for the environment (Kuraray Elastomer). This reduces air pollution and the risk of contributing to smog.

-

Health and Safety: Solvent-based adhesives can release harmful gases that require proper ventilation and safety precautions. In contrast, solvent-free adhesives eliminate these health risks, making them safer for users.

-

Regulatory Compliance: Adhering to regulatory standards is easier with solvent-free adhesives, as they produce fewer hazardous emissions, aligning with many environmental regulations (Kuraray Elastomer).

Considerations for Specific Projects

Choosing the appropriate adhesive depends on the specific requirements of your project. Here are some considerations:

| Project Type | Recommended Adhesive | Key Considerations |

|---|---|---|

| Home Repairs | Solvent-Free Adhesive | Safer for indoor use due to minimal fumes (Kuraray Elastomer) |

| Large-Scale Construction | Solvent-Based Adhesive | Stronger bonding properties may be required; consider ventilation needs (Chemique Adhesives) |

| Environmental Projects | Solvent-Free Adhesive | Eco-friendliness is crucial, reducing environmental footprint (Chemique Adhesives) |

| Automotive Repairs | Solvent-Based Adhesive | Higher temperature resistance and durability might be necessary |

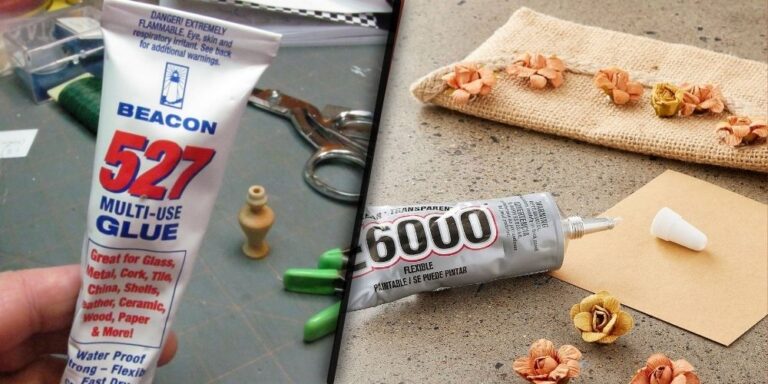

| Craft Projects | Solvent-Free Adhesive | Lower toxicity is important, especially for projects involving children |

For more specific applications and comparisons, check out related articles on 3m 90 vs. gorilla spray adhesive and metal glue vs. welding. To further explore safer alternatives, consider best adhesive for asphalt shingles or compare different products like e6000 vs. shoe goo adhesive.

Understanding these factors and considerations will guide you to the best adhesive for your project, ensuring both performance and safety.