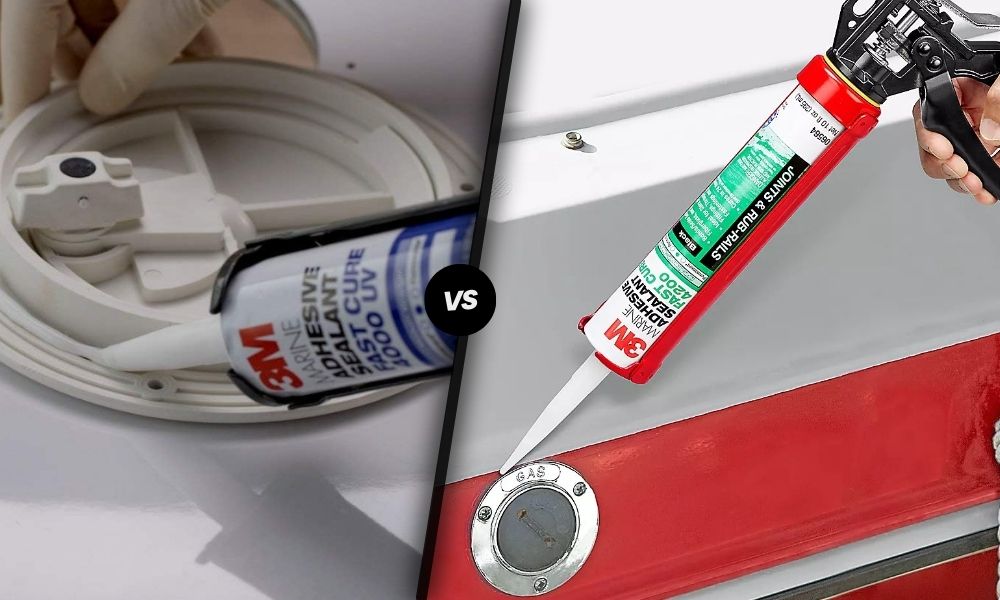

3M 4000 vs 4200: Marine Adhesive Guide

Comparing 3M 4000 and 4200 Marine Adhesives

Overview of 3M 4000 Marine Adhesive

The 3M™ Marine Adhesive Sealant Fast Cure 4000UV is designed to create strong, flexible, and semi-permanent seals on various marine surfaces such as RVs and boats. This adhesive typically cures within 24 hours, becoming tack-free in just 22 minutes (3M). Its formulation allows for immediate painting once cured, making it ideal for applications where aesthetics are important. Additionally, the 3M 4000UV is engineered to facilitate easy disassembly of boat parts without causing damage, which is a significant advantage in long-term maintenance and repairs.

Overview of 3M 4200 Marine Adhesive

The 3M™ Marine Adhesive Sealant 4200 shares many characteristics with the 3M 4000UV, notably its efficiency in stress dissipation caused by vibrations and shocks. This adhesive is especially valued for its resilience against salt, wind, weather, and temperature extremes, ensuring that it can stand up to various environmental conditions for prolonged periods (3M). Like the 4000UV, the 4200 is formulated to be highly durable and reliable, making it an ideal choice for marine applications where lasting performance is crucial.

| Feature | 3M 4000 | 3M 4200 |

|---|---|---|

| Curing Time | 24 hours | Similar to 4000 |

| Tack-Free Time | 22 minutes | Similar to 4000 |

| Paintability after Curing | Immediate | Not specified |

| Vibration and Shock Dissipation | High | High |

| Environmental Resistance | UV, Salt, Wind, Weather, Temperature | Salt, Wind, Weather, Temperature |

| Ease of Disassembly | Easy disassembly without damage | Not specified |

For more information on different types of adhesives, check out our articles on 3m 90 vs. gorilla spray adhesive, ca glue vs. epoxy, and elastomeric caulk vs. silicone.

Composition and Usage

Components of 3M 4000 Adhesive

The 3M™ Marine Adhesive Sealant Fast Cure 4000UV is formulated with polyether, providing a stable, flexible, and durable seal. It is UV-resistant, offering color stability even when exposed to sunlight. The polyether base ensures quick adhesion and remains elastic over time, making it ideal for applications requiring flexibility.

Components of 3M 4200 Adhesive

The 3M™ Marine Adhesive Sealant 4200 is also a polyether-based adhesive but formulated with slightly different properties aimed at providing strong, yet slightly less permanent bonds. It offers medium strength, suitable for applications where flexibility and the ability to disassemble parts is essential (3M).

Ideal Applications for 3M 4000

The 3M 4000 is well-suited for areas exposed to sunlight and situations where flexibility is crucial. It functions excellently for cosmetic seals over permanent adhesive materials and is perfect for the following applications:

- Wood

- Glass

- Gelcoat

- Fiberglass

- Metals

- Plastics

Topside components, including hatches, portlights, metal hardware, and porthole seals, particularly benefit from 3M 4000’s properties.

| Application Area | 3M 4000 Suitability |

|---|---|

| Wood | High |

| Glass | High |

| Gelcoat | High |

| Fiberglass | High |

| Metals | High |

| Plastics | High |

| Topside components | High |

Ideal Applications for 3M 4200

The 3M 4200 is designed for medium-strength bonding, ideal for parts that may require disassembly. It is appropriate for applications where moderate flexibility and a durable seal are required. Key applications include:

- Bonding portholes

- Deck fittings

- Rub rails

- Screw holes

- Stanchion supports

The 3M 4200 formulation provides color stability and UV resistance, suitable for both above and below the waterline applications.

| Application Area | 3M 4200 Suitability |

|---|---|

| Portholes | Medium-High |

| Deck fittings | Medium-High |

| Rub rails | Medium-High |

| Screw holes | Medium-High |

| Stanchion supports | Medium-High |

For more information on comparing adhesives and their applications, check out our articles on 3m 90 vs. gorilla spray adhesive and ca glue vs. epoxy.

Performance Characteristics

Understanding the performance characteristics of 3M 4000 and 4200 marine adhesives is crucial for making an informed decision. Here, we explore the strength, toughness, flexibility, and adhesive properties of these two products.

Strength and Toughness of 3M 4000

The 3M™ Marine Adhesive Sealant Fast Cure 4000UV is designed to provide durability and strength in marine applications. With a tensile strength of 500 psi and a hardness of 40 Shore A, it offers robust performance under dynamic forces (3M). The adhesive dissipates stress caused by vibration and shock, enhancing its toughness.

| Characteristic | 3M 4000 |

|---|---|

| Tensile Strength | 500 psi |

| Hardness | 40 Shore A |

| Modulus at 100% | > 250 psi |

Strength and Toughness of 3M 4200

The 3M™ Marine Adhesive Sealant Fast Cure 4200 also boasts impressive strength and durability, though specific numerical values are not provided. Like the 4000UV, it is designed to endure the rigors of marine environments, making it suitable for boat repairs and assembly. For exact figures, please refer to the product specifications on 3M’s official site.

Flexibility Comparison

Both 3M 4000 and 4200 adhesives offer flexibility, which is essential for marine applications that require movement and dynamic forces absorption. The 3M 4000UV, however, is particularly noted for its medium-strength adhesive properties, allowing for the assembly and disassembly of boat parts without causing damage. This indicates a higher degree of flexibility suitable for various applications.

Adhesive Properties

In terms of adhesive properties, both 3M 4000 and 4200 demonstrate exceptional performance:

- 3M 4000: This adhesive offers medium-strength adhesive properties, making it suitable for applications where components may need to be repositioned or disassembled without damage.

- 3M 4200: Designed for strong, semi-permanent bonds, 3M 4200 excels in situations where a high-strength bond is needed, but flexibility is also required.

For further information on how these products stack up against other adhesives, you can check our comparison articles like 3m 90 vs. gorilla spray adhesive and 3m headliner adhesive vs. super 77.

Understanding these performance characteristics helps in selecting the best adhesive for specific marine applications. Both the 3M 4000 and 4200 come highly recommended due to their strength, durability, and flexibility, making them excellent choices for marine environments.

Environmental Resistance

Assessing the environmental resistance of adhesives is essential, especially for demanding marine applications. Here, we compare the UV resistance, weather and temperature resistance, of 3M 4000 and 3M 4200 marine adhesives.

UV Resistance of 3M 4000

The 3M™ Marine Adhesive Sealant Fast Cure 4000UV is specifically designed for environments exposed to the sun. It boasts excellent UV resistance, making it suitable for both topside and deck applications. Its ability to withstand UV rays enables it to maintain its color and structural integrity even in prolonged sunlight exposure (3M). This makes it ideal for use on topside components like hatches, portlights, and metal hardware.

UV Resistance of 3M 4200

The 3M™ Marine Adhesive Sealant 4200 also offers moderate UV resistance, making it suitable for general marine applications. However, compared to 3M 4000, it may not perform as well in harsh, prolonged sunlight exposure. It’s better suited for below-deck applications or where UV exposure is limited.

Weather and Temperature Resistance

Both 3M 4000 and 4200 adhesives are designed to withstand a wide range of environmental conditions, including variations in temperature and weather. Here’s a comparison of their weather and temperature resistance properties:

| Property | 3M 4000 | 3M 4200 |

|---|---|---|

| UV Resistance | Excellent | Moderate |

| Temperature Range | -40°F to 190°F | -40°F to 190°F |

| Waterproof | Yes | Yes |

| Weather Resistance | High | High |

The 3M 4000 features a highly flexible and tough formula that allows it to perform well under dynamic conditions without cracking. It provides a firm, waterproof seal and allows for disassembly of parts without damage.

The 3M 4200 also offers reliable weather resistance, but it is more suitable for permanent bonding rather than applications that may require removal or disassembly. Both adhesives remain tack-free quickly and cure promptly, making them practical for various marine environments.

For additional guidance on selecting marine adhesives and sealants, explore our articles comparing 3m 90 vs. gorilla spray adhesive or solvent vs. solvent free adhesive. Understanding the specific needs of your project will help in choosing the right adhesive for optimal performance and longevity.

Application Methods

Application Procedures for 3M 4000

The 3M™ Marine Adhesive Sealant Fast Cure 4000UV is designed for ease of use, especially in marine environments. Here’s how to apply it effectively:

- Surface Preparation: Clean the surfaces to be bonded. Remove any dirt, oil, or old adhesive residues.

- Application: Cut the tip of the nozzle to the desired size. Apply the adhesive in continuous beads or dots to ensure even coverage.

- Tooling: Smooth the sealant using a tool or finger dipped in soapy water. This helps to remove air bubbles and ensure a tight seal.

- Setting: Position and align the parts quickly. Apply uniform pressure to ensure good contact between surfaces.

Application Procedures for 3M 4200

The 3M 4200 adhesive follows a similar procedure but requires attention to specific details due to its unique composition.

- Surface Preparation: Begin by thoroughly cleaning the bonding surfaces to remove any contaminants.

- Application: Cut the nozzle at an angle and apply the adhesive evenly along the surface.

- Tooling: Use a spatula or similar tool to flatten and spread the adhesive evenly.

- Setting: Quickly bring the surfaces together and apply consistent pressure to form a solid bond.

Curing Times

Each adhesive has its own curing time. Understanding these times ensures that the bond is complete and secure before use.

| Adhesive | Initial Cure Time | Full Cure Time |

|---|---|---|

| 3M 4000UV | 24 hours | 7 days |

| 3M 4200 | 1 hour | 24 hours |

Painting Compatibility

Painting over the adhesive is often necessary in marine applications for both aesthetic and protection purposes. Here’s how each adhesive fares:

- 3M 4000UV: This adhesive can be painted immediately after curing, allowing for rapid customization and finishes. This feature makes it ideal for projects requiring fast turnaround.

- 3M 4200: Generally, it is recommended to wait for the adhesive to fully cure before applying paint. This prevents any issues with the bonding and ensures the paint adheres properly.

For further detailed comparisons, explore our articles on other adhesive products:

Versatility and Longevity

When selecting a marine adhesive, understanding the longevity and versatility of the product is key. Let’s look at the specific characteristics of the 3M 4000 and 4200 adhesives.

Longevity of Seals with 3M 4000

The 3M™ Marine Adhesive Sealant Fast Cure 4000UV is known for forming long-lasting seals. With a tensile strength of 500 psi and a hardness of 40 Shore A, it cures to form a firm, flexible, and waterproof seal (3M). Its resistance to salt, wind, weather, and temperature extremes ensures it remains durable under various conditions.

| Property | Value |

|---|---|

| Tensile Strength | 500 psi |

| Hardness | 40 Shore A |

| Full Cure Time | >3.5 mm/24 hrs |

Longevity of Seals with 3M 4200

The 3M™ Marine Adhesive Sealant Fast Cure 4200 shares similar properties to the 4000UV in terms of longevity. It also forms strong bonds that can withstand stress caused by vibration and shock, making it suitable for dynamic marine environments. Its medium-strength adhesive properties allow for both assembly and disassembly of boat parts without damage, ensuring its usability over extended periods.

| Property | Value |

|---|---|

| Tensile Strength | Comparable to 4000UV |

| Hardness | Similar to 4000UV |

| Full Cure Time | Comparable to 4000UV |

Versatile Use Cases

Both the 3M 4000 and 4200 adhesives offer versatile applications. The 4000UV is particularly suitable for topside components, such as hatches, portlights, and metal hardware, and can be applied on a variety of substrates, including wood, glass, gelcoat, fiberglass, metals, and plastics (3M). The 4200 adhesive is ideal for below and above waterline applications, providing excellent adhesion to various substrates, ensuring it can be used in a variety of marine settings.

Maintenance Considerations

Maintaining adhesion and ensuring longevity involves several considerations:

- Surface Preparation: Ensure surfaces are clean and free of contaminants to achieve optimal adhesion.

- Application Technique: Follow recommended application procedures to avoid weak spots. For detailed application steps, refer to the sections on application procedures for 3M 4000 and application procedures for 3M 4200.

- Curing Time: Allow sufficient curing time to ensure the adhesive reaches its maximum strength. Both the 4000UV and 4200 offer fast curing, but full strength is achieved with patience.

- Protection: Utilize appropriate protective measures, such as applying a paintable sealant after curing, to extend the life of the sealant.

By understanding these aspects, users with questions regarding glue can effectively utilize 3M 4000 and 4200 adhesives for durable and versatile marine applications, ensuring their choice meets the demands of their specific use case.