Roo Glue vs Titebond: Wood Adhesive Showdown

Understanding Titebond Glues

Titebond Ultimate Wood Glue Overview

Titebond Ultimate Wood Glue is a versatile adhesive known for its strong hold and water resistance. It is designed to provide secure bonding for various woodworking projects and can be easily cleaned up with water before it dries (This Old House). Users appreciate its performance and reliability, especially in applications where moisture resistance is crucial.

Titebond Ultimate Wood Glue Features

The features of Titebond Ultimate Wood Glue make it a standout option for woodworking enthusiasts. Here are some of its key attributes:

- Strong Hold: Ensures a durable bond suitable for heavy-duty applications.

- Water Resistance: Ideal for outdoor projects or areas exposed to humidity.

- Food Safe: Suitable for items that may come into contact with food.

- Easy Cleanup: Excess glue can be cleaned up with water before it dries.

However, there are some disadvantages to consider:

- Clamp and Cure Time: Requires a longer time for clamping and curing, which may be inconvenient for quick projects.

- Dried Color: Dries to a light brown color that may not match all wood finishes.

- Bottle Issues: Some users have reported the bottle size being too small for larger projects and issues with clogged dispensers upon arrival.

| Feature | Details |

|---|---|

| Strong Hold | Provides a durable bond for heavy-duty projects |

| Water Resistance | Suitable for humid environments and outdoor projects |

| Food Safe | Can be used on items that contact food |

| Easy Cleanup | Water cleanup before the glue dries |

| Clamp and Cure Time | Longer clamping and curing period |

| Dried Color | Light brown color that may not match all wood finishes |

| Bottle Issues | Reports of small bottle size and clogged dispensers |

Internal Links

For more insights about different adhesives, visit our articles on:

These articles can provide additional comparisons and help you choose the best adhesive for your specific needs.

Titebond vs. Hide Glue for Guitars

The choice between Titebond and Hide Glue can significantly impact the construction and repair of guitars. Both adhesives are widely used in the industry, but they have unique characteristics that make them suitable for different applications. Understanding their differences and their effects on guitar construction can help in making an informed decision.

Comparison of Titebond and Hide Glue

Titebond and Hide Glue are both highly regarded for their adhesive properties, but they differ in composition, reversibility, and long-term effects on the material.

- Composition: Titebond is a synthetic aliphatic resin glue, known for its strong bonds and durability. Hide Glue, derived from animal collagen, forms through a molecular bonding process.

- Reversibility: Hide Glue is preferred for its reversible properties. It allows joints to be taken apart without removing any wood, which is crucial for repairs and restorations (Guitar Craftsmanship). Titebond, on the other hand, requires sanding or scraping to expose fresh wood for regluing, which can result in material loss.

- Handling during Repairs: When heated, Hide Glue softens, enabling easy separation of parts. Titebond retains its stay power even after softening, leaving a mass of rubbery resin that needs to be scraped off.

| Titebond | Hide Glue | |

|---|---|---|

| Composition | Aliphatic resin | Animal collagen |

| Reversibility | Partial, requires sanding | Full, easy to separate |

| Bond Strength | Strong, durable | Strong, reversible |

| Repair Challenge | Difficult, requires scraping | Easy, softens with heat |

Considerations for Guitar Construction

When constructing guitars, several factors must be considered to determine whether Titebond or Hide Glue is more appropriate:

- Sound Quality: The thickness of the glue layer can impact sound quality. Hide Glue, with its thin molecular bond, is often preferred for its minimal impact on vibration and resonance. For craftsmanship-level guitar work, this can be crucial.

- Material Preservation: Hide Glue allows for easier preservation of the original sizes, thicknesses, and specifications of the wood. This is especially important for valuable collector’s instruments where maintaining the instrument’s authenticity is key.

- Repair and Restoration: If future repairs are anticipated, using Hide Glue is generally recommended. Its reversible nature ensures that parts can be separated and reassembled without significant damage to the wood. Titebond’s partial reversibility can present challenges, especially for intricate instruments where even minor loss of wood can affect the sound and playability.

- Application Convenience: Titebond is often easier and quicker to apply, making it a popular choice for initial construction. However, for specific needs in high craftsmanship and restorative work, Hide Glue’s benefits outweigh the convenience of Titebond.

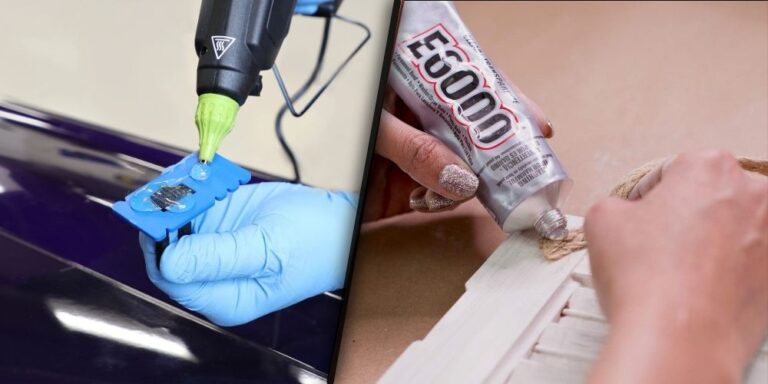

For more detailed comparisons, you may refer to our articles on other glue comparisons such as e6000 vs. shoe goo or the potential issues with certain adhesives, like e6000 glue not working.

Choosing the right glue for your guitar construction or repair project hinges on understanding these key differences and aligning them with your specific needs. This ensures not only a strong bond but also the preservation of the instrument’s integrity and sound quality.

Titebond III Characteristics

Benefits of Titebond III

Titebond III is a standout wood adhesive known for its versatility and robust performance in various applications. It’s especially favored for its extended open time, waterproof properties, and impressive strength.

- Extended Open Time: Titebond III offers twice the open time compared to Titebond II and Original, making it an excellent choice for complex glue-ups where more working time is needed (The Wood Whisperer).

- Waterproof: This glue passes the Type I ANSI/HPVA water resistance test, making it suitable for projects exposed to ambient moisture or short periods of submersion, and even steam or boiling water (The Wood Whisperer).

- Strength: Despite losing some strength at higher temperatures, Titebond III exhibits strong shear strength at 800 psi at 150 degrees (The Wood Whisperer).

Applications of Titebond III

Titebond III’s unique properties make it suitable for a variety of woodworking projects, from standard indoor tasks to more demanding outdoor applications.

- Indoor Woodworking: Ideal for furniture making, cabinetry, and other woodworking projects where a strong and durable bond is required. The extended open time allows for precise assembly and complex glue-ups.

- Outdoor Projects: Due to its waterproof nature, Titebond III is perfect for outdoor furniture, garden structures, and other projects exposed to the elements.

- High-Moisture Environments: Suitable for use in kitchens, bathrooms, and other areas where steam or boiling water exposure is a factor.

| Feature | Titebond III |

|---|---|

| Open Time | Twice the time of Titebond II and Original |

| Waterproof | Passes Type I ANSI/HPVA test |

| Shear Strength | 800 psi at 150 degrees |

For additional information on adhesive comparisons and specific applications, explore our related articles on 3m 4000 vs. 4200 marine adhesive, 3m 90 vs. gorilla spray adhesive, and hide glue vs. titebond.

Pricing and Varieties of Titebond Glues

Choosing the right adhesive can transform a woodworking project. Titebond is renowned for its range of wood glues, each designed to meet specific needs. Understanding the pricing and varieties of Titebond glues is essential for making an informed choice.

Titebond Glue Price Comparison

Price plays a significant role when selecting a glue for your project. Below is a table compiling the prices of various Titebond glues to help you compare:

| Titebond Glue Type | Price (Quart Size) |

|---|---|

| Titebond Original | $8.59 |

| Titebond II | $10.49 |

| Titebond III | $13.99 |

The table highlights that Titebond III is the most expensive, reflecting its advanced features. Titebond Original, on the other hand, is the most budget-friendly, offering essential bonding capabilities at a lower cost.

Range of Titebond Glue Options

Titebond caters to a suite of woodworking needs with its diverse glue offerings, suitable for everything from interior applications to construction adhesives. Below is an overview of the primary types of Titebond glues and their applications:

- Titebond Original: Ideal for interior woodworking projects. It dries quickly and provides a strong initial tack.

- Titebond II: Suitable for both interior and exterior use. It offers water resistance, making it great for projects exposed to moisture but not direct outdoor conditions.

- Titebond III: The premium choice for exterior projects. It provides superior water resistance and extends working time, ideal for more complex assemblies.

For a comprehensive selection guide, visit our Titebond Glue Selection Guide.

| Glue Type | Interior Uses | Exterior Uses | Water Resistance | Working Time |

|---|---|---|---|---|

| Titebond Original | ✓ | ✗ | ✗ | Standard |

| Titebond II | ✓ | ✓ | ✓ | Standard |

| Titebond III | ✓ | ✓ | ✓✓ | Extended |

This table provides a quick reference on what each Titebond product is best suited for, helping you match the glue to your project requirements. By understanding the differences between the various Titebond glues, you can select the adhesive that best meets your needs.

For further comparisons with other adhesives, check out our articles on 3m spray adhesive 90 vs. 77 and ca glue vs. epoxy.

Specific Applications of Titebond Glues

Titebond glues are highly versatile and cater to a wide range of applications, from building furniture to repairing musical instruments. Understanding the specific uses of each type of Titebond glue can help you make an informed decision.

Titebond Glue Selection Guide

Choosing the right Titebond glue depends on the specifics of your project. Below is a guide outlining various Titebond products and their ideal uses:

| Titebond Product | Type | Ideal Use Cases |

|---|---|---|

| Titebond Original | Aliphatic Resin | Interior wood projects like furniture, cabinets, and biscuit joints. Bonds wood, hardboard, leather, cloth |

| Titebond Liquid Hide | Natural Protein Emulsion | Furniture repair and decorative woodworking. Suitable for creating a crackling effect on wood and cloth |

| Titebond Polyurethane | Polyurethane | Bonding various materials like wood, metals, ceramics, and most plastics. Suitable for both interior and exterior use |

| Titebond III | Advanced Proprietary | Outdoor projects needing waterproofing, strong initial tack, and sandability. Ideal for cutting boards and kitchenware (Axminster Tools) |

Recommended Uses of Titebond Products

Titebond Original:

Titebond Original is best for interior wood projects due to its strong bond and versatility. It’s especially favored by professional cabinetmakers and DIY enthusiasts for furniture and cabinet making because it bonds well with wood, hardboard, and porous materials such as leather and cloth. For detailed guidance on using Titebond Original in woodworking, visit our guide.

Titebond Liquid Hide:

Liquid Hide glue is ideal for antique furniture repairs and crafting projects that require a unique crackling effect on wood and cloth. Since it doesn’t require heating or mixing, it’s user-friendly and perfect for intricate job roles like guitar construction. For more insights into why Liquid Hide glue is a popular choice in musical instrument repair, explore our comparison of hide glue vs. titebond.

Titebond Polyurethane:

This glue is excellent for projects requiring strong bonds on various materials, including metals and ceramics. Titebond Polyurethane’s Type II water resistance makes it a great choice for exterior applications. Utilize it in outdoor furniture, decking, and other construction projects that demand durability and water resistance. Learn more about the best adhesives for outdoor projects here.

Titebond III:

With Titebond III, you achieve superior waterproofing which makes it the go-to option for projects that will be exposed to water. Its benefits include long assembly time, strong initial tack, and excellent sandability, making it excellent for cutting boards and kitchenware. To delve into more aspects of Titebond III, check out our detailed section on Titebond III characteristics.

By selecting the right Titebond glue for your project, you can ensure strong, durable bonds and achieve the best results. For additional comparisons of adhesives suitable for various applications, explore our articles on 3m 4000 vs. 4200 marine adhesive and flex seal vs. silicone.

Performance and Durability of Titebond Glues

Strength of Titebond III

Titebond III is renowned for its robust performance and strength, particularly in complex woodworking projects that require a long open time. It offers twice the open time compared to Titebond II and Original, making it ideal for intricate glue-ups that need precision (The Wood Whisperer). However, its strength diminishes with increasing temperature; at 150 degrees Fahrenheit, its shear strength drops to 800 psi.

| Property | Titebond III |

|---|---|

| Open Time | Twice that of Titebond II & Original |

| Shear Strength at 150°F | 800 psi |

| Waterproof | Yes |

Water Resistance and Type I ANSI/HPVA Test

Titebond III excels in applications where water resistance is crucial. It meets the Type I ANSI/HPVA standard, which is the most rigorous test for water resistance in adhesives. This makes Titebond III suitable for projects exposed to ambient moisture or even short periods of submersion, such as outdoor furniture or kitchen countertops (The Wood Whisperer).

| Test Standard | Result |

|---|---|

| Type I ANSI/HPVA | Passed |

| Exposure Suitability | Moisture & Steam |

Despite its excellent performance, it’s important to note that Titebond III might not be suitable for all projects due to its light brown dried color, which may not match all wood finishes. This should be considered when selecting the best wood adhesive for your project.

For more in-depth comparisons, check out our articles on hide glue vs. titebond and the best adhesive for asphalt shingles.