Gorilla Spray Adhesive vs 3M 77: Bond Test

Product Overview

Two prominent options in the adhesive market are Gorilla Spray Adhesive and 3M Super 77 Multipurpose Spray Adhesive. Each has unique features that cater to different needs, making them suitable for a variety of projects.

Gorilla Spray Adhesive Features

Gorilla Spray Adhesive is a heavy-duty, multi-purpose adhesive designed for various applications. Here are some of its key features:

- Versatility: Utilized on surfaces such as fabric, paper, wood, plastic, cardboard, foam, and metal (Gorilla Tough) (FindTape).

- Durability: Forms a clear, permanent bond that is moisture resistant, making it ideal for both indoor and outdoor projects.

- Safety: Safe for photographs and can be sanded and painted to match surfaces.

- Limitations: Not suitable for polypropylene (PP), polyethylene (PE) plastics, vinyl, or any material with high oil or plasticizer content. Avoid use on food contact surfaces or for bonding heavily weighted materials.

3M Super 77 Multipurpose Spray Adhesive Features

The 3M™ Super 77™ Multipurpose Spray Adhesive is renowned for its consistency and adaptability over the last five decades. Here are some of its primary attributes:

- Reliability: Known for its high level of reliability in numerous applications worldwide.

- Quick Drying: Features fast-drying capabilities suitable for a myriad of lightweight materials (3M).

- Aggressive Tack: Offers an aggressive tack with a high initial grab and ample open time for accurate positioning of materials.

- Versatility: Ideal for various projects, accommodating different types of lightweight materials.

This overview presents an initial comparison of these two adhesives, highlighting their specific features and ideal use cases. For more detailed comparisons of other adhesives, such as 3m 90 vs. gorilla spray adhesive, check out our additional articles.

Suitable Surfaces

Choosing the correct adhesive for your project is crucial for achieving optimal results. In this section, we will explore the surfaces compatible with Gorilla Spray Adhesive and 3M Super 77 Multipurpose Spray Adhesive.

Compatible Materials with Gorilla Spray Adhesive

Gorilla Spray Adhesive is a versatile, heavy-duty adhesive suitable for various surfaces. It forms a clear, permanent bond that is moisture-resistant and can be used indoors and outdoors.

| Material | Compatibility |

|---|---|

| Fabric | Yes |

| Paper | Yes |

| Wood | Yes |

| Plastic | Yes (except PP and PE) |

| Cardboard | Yes |

| Foam | Yes |

| Metal | Yes |

| Photographs | Yes |

| Vinyl | No |

| Polypropylene (PP) | No |

| Polyethylene (PE) | No |

| Rubber (high oil/plasticizer content) | No |

| Food Contact Surfaces | No |

| Automotive Headliners | No |

| Weighted Materials | No |

Gorilla Spray Adhesive is also sandable and paintable, making it ideal for various DIY and craft applications. For projects involving vinyl or specific types of plastics and rubbers, consider alternative adhesives like those listed in 3m 4000 vs. 4200 marine adhesive or 3m 90 vs. gorilla spray adhesive.

Compatible Materials with 3M Super 77 Multipurpose Spray Adhesive

3M Super 77 Multipurpose Spray Adhesive is another versatile adhesive known for its strong bonding capabilities and environmental consciousness. It is suitable for a wide range of materials and applications.

| Material | Compatibility |

|---|---|

| Paper | Yes |

| Cardboard | Yes |

| Fabric | Yes |

| Insulation | Yes |

| Plastic | Yes |

| Metal | Yes |

| Wood | Yes |

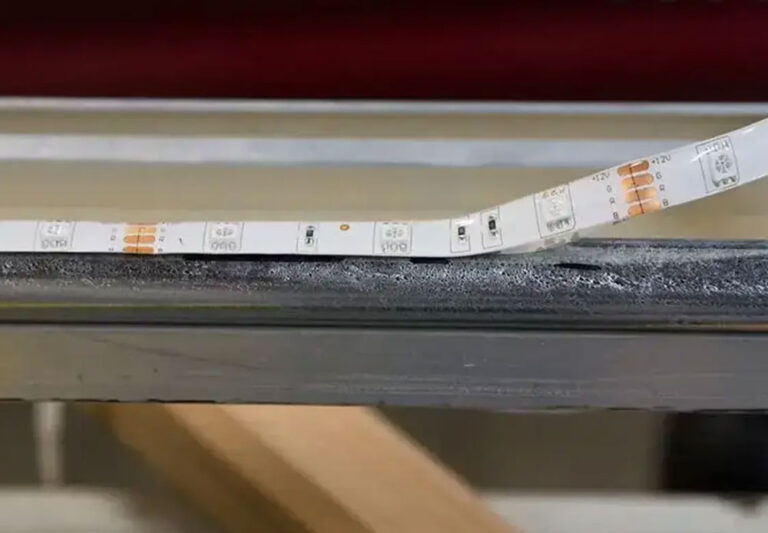

3M Super 77 Multipurpose Spray Adhesive is also compliant with low VOC levels and eligible for LEED credits, making it an environmentally responsible choice. This spray adhesive is effective in insulation attachment and large surface lamination assembly. For more complex applications involving adhesives, you may also want to see our comparison on 3m spray adhesive 90 vs. 77.

By understanding the compatible materials with both Gorilla Spray Adhesive and 3M Super 77 Multipurpose Spray Adhesive, you can better determine which product will meet the specific demands of your project. For further information on adhesives and their applications, explore related topics like ca glue vs. epoxy and metal glue vs. welding.

Application Guidelines

Best Practices for Using Gorilla Spray Adhesive

Using Gorilla Spray Adhesive effectively ensures strong, lasting bonds. Here are some best practices for optimal results:

- Surface Preparation: Ensure that the surfaces to be bonded are clean, dry, and free from any dirt, grease, or debris.

- Temperature and Ventilation: Apply at temperatures between 60°F and 80°F in a well-ventilated area.

- Application:

- Shake the can well before use.

- Spray an even coat from a distance of about 6-8 inches.

- For stronger bonds, apply two coats: one on each surface, allowing the first coat to dry for about 1-3 minutes before pressing the surfaces together.

- Bonding:

- Join the materials promptly after spraying.

- Apply pressure for a few seconds to ensure good contact.

- Cleaning and Storage:

- Clean the nozzle after use to prevent clogging.

- Store in a cool, dry place.

For additional guidance on using Gorilla Spray Adhesive, consider visiting our article on 3m 90 vs. gorilla spray adhesive.

Best Practices for Using 3M Super 77 Multipurpose Spray Adhesive

3M Super 77 Multipurpose Spray Adhesive is known for its strong, versatile bonds. Follow these steps for effective use:

- Surface Preparation: Make sure surfaces are clean, dry, and free from contaminants.

- Optimal Conditions:

- Apply at temperatures between 65°F and 95°F.

- Work in a well-ventilated area.

- Application:

- Shake the can well.

- Spray an even coat on both surfaces from a distance of approximately 6-8 inches.

- Allow 15-30 seconds for the adhesive to become tacky before bonding materials.

- Bonding:

- Align parts properly and press firmly together.

- The bond will reach its full strength in about 1 hour.

- Cleaning and Storage:

- Clean the nozzle after each use.

- Store upright in a cool, dry place.

For comprehensive information on 3M Super 77 Multipurpose Spray Adhesive, see our article on 3m spray adhesive 90 vs. 77.

For a quick comparison of the two products:

| Adhesive | Temperature Range (°F) | Tack Time | Full Bond Strength |

|---|---|---|---|

| Gorilla Spray Adhesive | 60-80 | 1-3 minutes | A few seconds |

| 3M Super 77 | 65-95 | 15-30 seconds | 1 hour |

To explore more about adhesives, check out our articles on flex glue vs. flex seal and pva glue vs. elmer.

Safety Measures

Handling and Storage of Gorilla Spray Adhesive

Gorilla Spray Adhesive requires careful handling and storage to ensure safety:

- Flammability: This adhesive is flammable and must be kept away from heat sources, sparks, open flames, and smoking areas.

- Storage Temperature: It should not be stored at temperatures exceeding 120°F to prevent clogging.

- Nozzle Maintenance: After each use, the nozzle should be wiped with a dry cloth. To avoid clogging, spray a short jet of clear gas after finishing.

- Cap Replacement: Always replace the cap after use to maintain the integrity of the adhesive.

By adhering to these guidelines, users can safely utilize Gorilla Spray Adhesive without risk.

Handling and Storage of 3M Super 77 Multipurpose Spray Adhesive

3M Super 77 Multipurpose Spray Adhesive also has specific handling and storage instructions:

- Flammability: This product is aerosol-based and should be kept away from heat, sparks, and open flames.

- Storage Instructions: Store in a cool, dry place away from direct sunlight and temperatures exceeding 120°F.

- Open Time: The adhesive has an open time of 1 to 15 minutes.

- Heat Resistance: It can withstand temperatures up to 150°F (66°C).

- Maintenance: The nozzle should be cleaned after use to prevent clogging.

By following these precautionary steps, users can safely utilize 3M Super 77 Multipurpose Spray Adhesive.

Comparing the safety measures and handling instructions for both adhesives, users can determine the best practices to ensure safe storage and use. For additional information on adhesives, explore topics like 3m 90 vs. gorilla spray adhesive or 3m headliner adhesive vs. super 77.

Environmental Impact

With increasing awareness about environmental sustainability, it’s crucial to consider the environmental impact of adhesive products. This section compares the VOC levels and sustainability features of Gorilla Spray Adhesive and 3M Super 77 Multipurpose Spray Adhesive.

VOC Levels Comparison

Volatile Organic Compounds (VOCs) contribute to air pollution and can have adverse health effects. Understanding the VOC levels of adhesive sprays can help users make more environmentally conscious choices.

| Adhesive | VOC Level |

|---|---|

| Gorilla Spray Adhesive | < 30% |

| 3M Super 77 Multipurpose Spray Adhesive | Low VOC, CARB-compliant |

Gorilla Spray Adhesive meets VOC standards with less than 30% VOC content in its mist spray adhesive (FindTape). On the other hand, 3M Super 77 Multipurpose Spray Adhesive is noted for its low VOC levels and CARB compliance, making it a more environmentally friendly option (3M). These features make it eligible for LEED credits, which are points awarded for adhering to green building principles.

Sustainability Features

Sustainability features extend beyond VOC levels and include aspects like recyclability, energy efficiency, and overall impact on the environment.

Gorilla Spray Adhesive

- Environmentally responsible with low VOC mist.

- Designed for controlled, even application, which minimizes waste.

3M Super 77 Multipurpose Spray Adhesive

- Composed of high-solids content, supporting low soak-in properties and higher coverage, leading to reduced consumption.

- Versatile application across various industries, ensuring broad utility and reduced need for multiple products.

- Low VOC, CARB compliance, eligible for LEED credits (3M).

For further information on adhesive comparisons, explore related articles like 3m spray adhesive 90 vs. 77, 3m headliner adhesive vs. super 77, and solvent vs. solvent free adhesive.

Understanding these environmental impacts helps in making informed decisions. Both Gorilla Spray Adhesive and 3M Super 77 offer environmentally conscious solutions, but the 3M product provides additional sustainability benefits like LEED eligibility. Always consider the overall environmental footprint when choosing adhesive products.

Pricing and Availability

Comparing the costs and availability of Gorilla Spray Adhesive and 3M Super 77 Multipurpose Spray Adhesive can help consumers make an informed decision.

Cost Analysis of Gorilla Spray Adhesive

Gorilla Spray Adhesive is available in different sizes, which affects the pricing. Prices for Gorilla Spray Adhesive, depending on size and quantity, are as follows:

| Product Size | Price (USD) |

|---|---|

| 4 oz. Single | $6.24 |

| 14 oz. Single | $9.96 |

For further details on Gorilla Spray Adhesive, visit FindTape.

Cost Analysis of 3M Super 77 Multipurpose Spray Adhesive

3M™ Super 77™ Multipurpose Spray Adhesive is designed for versatile use and comes in different container sizes. Prices for 3M Super 77, based on container volume, are as follows:

| Product Size | Price (USD) |

|---|---|

| 16 fl oz. (US) | Varies by retailer |

| 24 fl oz. (US) | Varies by retailer |

3M Super 77 can contribute to LEED® credits and is widely available. For more information, refer to 3M.

These adhesives are both readily available across various hardware and online stores. Determining the best choice may include factors such as pricing, quantity needed, and specific application requirements. For more comparisons between adhesives, visit our discussions on 3m 4000 vs. 4200 marine adhesive and 3m 90 vs. gorilla spray adhesive.