PC 7 Epoxy vs. JB Weld: Heavy-Duty Bond Test

Understanding PC-7 Epoxy

Exploring the characteristics and advantages of PC-7 epoxy is essential to determine its suitability for various applications compared to other adhesives like J-B Weld. This section provides an overview of its core features.

Introduction to PC-7 Epoxy

PC-7 epoxy paste was originally formulated over 60 years ago for maximum bonding power, making it a reliable choice for both professionals and do-it-yourself enthusiasts. It is designed for permanent repairs and boasts exceptional adhesion to diverse materials, including metals, ceramics, masonry, and many plastics (PC Products). The slow-curing nature of PC-7 epoxy, which offers a working time of 60 minutes and requires 24 hours to cure (48 hours for full cure), is particularly beneficial for large tasks.

Benefits of PC-7 Epoxy

PC-7 epoxy offers various benefits that contribute to its popularity:

- Strong Adhesion: It adheres robustly to multiple surfaces such as wood, metals, glass, fiberglass, plastics, rubber, masonry, and ceramics. For comparisons with other adhesives, see jb weld vs. gorilla glue.

- Versatile Application: The high viscosity allows it to be applied in any thickness and used for vertical repairs without dripping or sagging (PC Products).

- Non-Air Dependent Cure: Unlike some epoxies, PC-7 does not require exposure to air for curing; it cures from the inside out. It initially remains soft or flexible even after 24 hours, attaining full hardness after an additional 24 hours.

- Longer Working Time: With a working time of 60 minutes, it provides ample time for adjustments during application, which can be critical for complex or extensive repairs.

- Permanent Bonding: PC-7 epoxy is engineered for permanent repairs, ensuring long-lasting durability.

| Property | Description |

|---|---|

| Working Time | 60 minutes |

| Initial Cure Time | 24 hours |

| Full Cure Time | 48 hours |

| Application Thickness | Can be applied in any thickness |

| Viscosity | High, prevents dripping or sagging |

| Curing Mechanism | Cures from the inside out, does not require air exposure |

| Surfaces Compatibility | Wood, metals, glass, fiberglass, plastics, rubber, masonry, ceramic, and more |

For more details on the compatibility and various effectiveness aspects, check out belzona epoxy vs. jb weld epoxy.

Understanding these benefits highlights why PC-7 epoxy stands out as a powerful adhesive solution compared to others like J-B Weld Original. For more in-depth comparisons and to find out which works best for your specific needs, take a look at our articles on epoxy vs. super glue and e6000 vs. gorilla glue.

Working with PC-7 Epoxy

Understanding the application, curing process, and customization of PC-7 epoxy is essential for achieving the best results.

Application of PC-7 Epoxy

PC-7 epoxy is known for its versatility and ease of application. It can be applied in any thickness and is suitable for vertical repairs due to its high viscosity, which prevents dripping or sagging (PC Products).

To apply PC-7 epoxy, follow these steps:

- Surface Preparation: Clean the surfaces to ensure they are free from mold release agents, dust, dirt, oil, and grease.

- Mixing: Squeeze and blend equal parts of the two components until the color is uniform.

- Applying: Use a spatula or putty knife to spread the epoxy evenly over the surface.

The table below compares the application specifics of PC-7 epoxy and J-B Weld:

| Adhesive | Working Time | Setting Time | Cure Time | Ideal Thickness |

|---|---|---|---|---|

| PC-7 Epoxy | 60 minutes | 24 hours | 48 hours | Any thickness |

| J-B Weld Original | 30 minutes | 4-6 hours | 15-24 hours | Thin |

For more adhesive comparisons, read our article on jb weld vs. gorilla glue.

Curing Process of PC-7 Epoxy

PC-7 epoxy provides a slow curing advantage, especially beneficial for large tasks. Here’s what you need to know about its curing process:

- Initial Set: The epoxy begins setting in approximately 60 minutes.

- Handling Time: The working time allows you to make adjustments or corrections within this period.

- Cure Time: While it sets in 24 hours, it takes a full 48 hours to achieve complete hardness (PC Products).

Unlike adherents needing exposure to air for curing, PC-7 epoxy cures from the inside out and remains slightly flexible for 24 hours before hardening fully.

Tinting and Customizing PC-7 Epoxy

PC-7 epoxy’s formula allows for customization through tinting to match the color of its surrounding environment. While it can be tinted using iron oxide or carbon pigments, it’s crucial to exercise caution. Overuse of tint may affect the epoxy’s performance (PC Products).

To tint PC-7 epoxy:

- Add Pigment: Mix the chosen pigment slowly into one part of the epoxy.

- Mix Thoroughly: Ensure an even distribution of pigment before combining with the second part of the epoxy.

For further guidance on using and customizing adhesives, check out our resource on wood glue vs. white glue.

Understanding the working properties of PC-7 epoxy ensures a successful application and curing process, leading to a durable and reliable bond. For quick reference and efficiency comparisons, see how long does it take for jb weld to dry.

Strength and Durability

When comparing the strength and durability of PC-7 Epoxy and J-B Weld Original, both adhesives offer impressive capabilities for heavy-duty bonding. However, there are noticeable differences in their tensile strength and overall performance that are worth considering.

Tensile Strength of PC-7 Epoxy

PC-7 Epoxy is renowned for its strong adhesive properties and is often used for permanent repairs. It boasts a tensile strength of 2150 PSI (Adhere Mate), making it suitable for various applications that require a reliable, durable bond. This high tensile strength ensures that PC-7 can handle significant stress without breaking or failing.

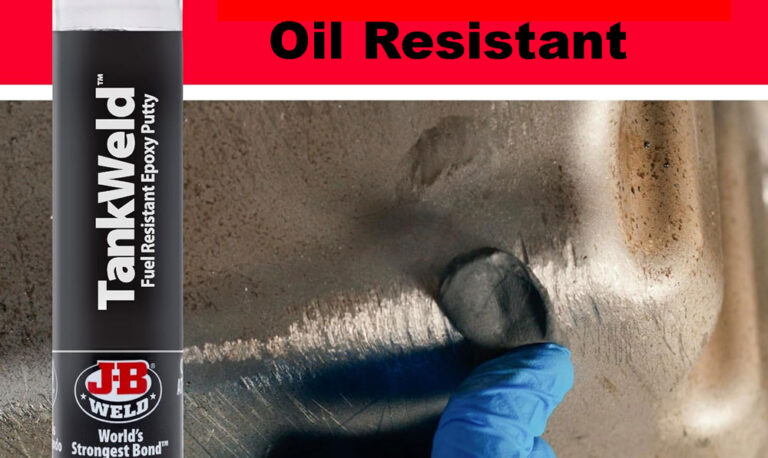

Comparison with J-B Weld Original

In contrast, J-B Weld Original Cold-Weld provides an even higher level of strength, with a tensile strength of 5020 PSI (Adhere Mate). This makes J-B Weld Original a stronger option for projects that require maximum durability and support.

| Adhesive | Tensile Strength (PSI) |

|---|---|

| PC-7 Epoxy | 2150 |

| J-B Weld Original | 5020 |

While both PC-7 Epoxy and J-B Weld Original are excellent for heavy-duty use, J-B Weld Original offers a superior tensile strength, making it the preferable choice for the most demanding applications.

For further discussions on adhesives and their applications, you may find our articles on epoxy vs. super glue and wood glue vs. white glue helpful. To explore more about how durable these adhesives are in various scenarios, visit our guide on jb weld vs. gorilla glue.

Versatility of PC-7 Epoxy

PC-7 epoxy is renowned for its versatility, making it ideal for a multitude of projects. Whether you’re working on household repairs or artistic creations, understanding the compatible and incompatible surfaces is crucial.

Compatible Surfaces with PC-7 Epoxy

PC-7 epoxy successfully bonds with a variety of surfaces, ensuring solid and durable repairs. Below is a comprehensive list of compatible surfaces:

- Wood: Suitable for furniture repair and wooden crafts.

- Metals: Effective for automotive repairs and metal bonding.

- Glass: Ideal for glass fixtures and decorative items.

- Fiberglass: Great for marine repairs and fiberglass bodywork.

- Plastics: Works with most hard plastics; however, always test a small area first.

- Rubber: Bonds well with stiff rubber; useful for rubber gaskets and seals.

- Masonry: Adheres to bricks and concrete for construction repairs.

- Ceramic: Suitable for pottery and ceramic fixtures.

Surfaces to Avoid with PC-7 Epoxy

While PC-7 epoxy is versatile, it has limitations when it comes to certain materials. Here are the surfaces to avoid:

- Wax Paper: The epoxy will not bond properly.

- Vinyl: Incompatibility leads to poor adhesion.

- Teflon: Known for its non-stick properties, making bonding impossible.

- Plexiglass: Typically, it does not form a solid bond.

- Softer Plastics: This includes materials like polypropylene and polyethylene.

| Surface Type | Compatibility |

|---|---|

| Wood | Yes |

| Metals | Yes |

| Glass | Yes |

| Fiberglass | Yes |

| Plastics | Yes, but test a small area first |

| Rubber | Only rigid rubber |

| Masonry | Yes |

| Ceramic | Yes |

| Wax Paper | No |

| Vinyl | No |

| Teflon | No |

| Plexiglass | No |

| Softer Plastics | No |

Understanding the versatility and limitations of PC-7 epoxy will help you achieve the best results for your projects. For comparisons with other adhesives like J-B Weld, read our jb weld vs. gorilla glue and devcon vs. jb weld articles.

Temperature and Chemical Resistance

Understanding the temperature and chemical resistance of PC-7 Epoxy is vital for individuals looking to choose between PC-7 Epoxy and J-B Weld for their heavy-duty bonding needs. Both products offer distinct advantages in varied environments.

Temperature Range for PC-7 Epoxy

PC-7 Epoxy operates effectively within a specific temperature range, essential for ensuring a strong and reliable bond in various conditions.

| Parameter | PC-7 Epoxy | J-B Weld Original |

|---|---|---|

| Minimum Temperature | -30°C | -67°F (-55°C) |

| Maximum Temperature | 95°C | 550°F (287°C) |

PC-7 Epoxy can withstand temperatures from -30°C to 95°C. This makes it suitable for use in moderate temperature conditions. In contrast, J-B Weld Original can tolerate higher heat, up to 550°F (287°C), making it viable for applications requiring greater heat resistance (Adhere Mate). For more comparisons, you can check our articles like belzona epoxy vs. jb weld epoxy and how long does it take for jb weld to dry.

Chemical Resistance of PC-7 Epoxy

PC-7 Epoxy is renowned for its robustness against various chemicals, making it a versatile choice for numerous applications.

| Chemical | PC-7 Epoxy | J-B Weld Original |

|---|---|---|

| Caustics | Resistant | Resistant |

| Mild Acids | Resistant | Resistant |

| Gasoline | Resistant | Resistant |

| Fuel | Resistant | Resistant |

| Oil | Resistant | Resistant |

| Fresh Water | Resistant | Resistant |

| Salt Water | Resistant | Resistant |

| Detergents | Resistant | Resistant |

| Petroleum | Not specifically indicated | Resistant |

PC-7 Epoxy resists chemicals like caustics, mild acids, gasoline, fuel, oil, fresh water, salt, and detergents without dripping or sagging (Adhere Mate). This high level of chemical resistance makes it ideal for applications where exposure to such substances is expected. Similarly, J-B Weld Original exhibits resistance to several chemicals including fuel, acid, and petroleum once fully cured.

For a deeper dive into other adhesive comparisons, consider visiting our related articles such as loctite pl marine vs. 5200 and rapid fuse vs. super glue. These resources provide additional insights into the strengths and limitations of various adhesives in a range of conditions.