Contact Cement vs Wood Glue: Project Guide

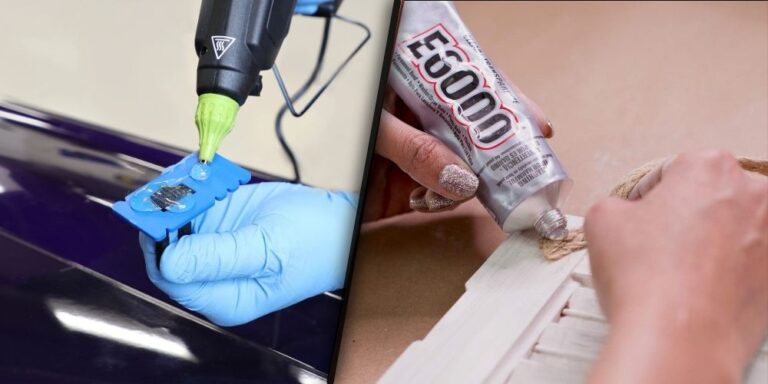

Glue Types Overview

Understanding the features and strengths of different glue types is essential when deciding between contact cement and wood glue. Each adhesive has its unique properties tailored for specific applications.

Contact Cement Features

Contact cement is an adhesive known for its fast bonding and ease of use, making it ideal for projects requiring efficiency.

- Quick Bonding: Once applied, contact cement forms an immediate bond, reducing wait times.

- Versatility: Suitable for a variety of surfaces including plastic laminates and metal.

- Durability: Solvent-based contact cement provides a long-lasting bond, especially effective in connecting pieces such as plywood.

- Use Case Limitation: Not ideal for single sheets of veneer or solid wood furniture (Fine Woodworking Forum).

| Feature | Description |

|---|---|

| Bonding Time | Immediate |

| Ideal Surfaces | Plastic laminate, metal, plywood |

| Durability | Long-lasting with solvent-based varieties |

| Limitations | Not suitable for single sheets of veneer, thick and rubbery texture |

For more detailed insights, visit our comprehensive guide on shoe goo vs. contact cement.

Wood Glue Strengths

Wood glue is commonly used in woodworking projects due to its strong adhesion properties and ease of use for wooden materials.

- Strong Bond: Provides an excellent bond for wood-to-wood applications.

- Flexibility: Easily handles the expansion and contraction of wood.

- Varieties: Includes PVA (polyvinyl acetate) and aliphatic resin glues, each suited for different purposes.

- Application Ease: Easy to apply and clean up, making it suitable for various woodworking projects.

| Feature | Description |

|---|---|

| Bonding Time | Requires clamping for several hours |

| Ideal Surfaces | Wood, wood composites |

| Durability | Highly durable when dried |

| Flexibility | Accommodates wood movement |

For specific comparisons, explore our article on construction adhesive vs. wood glue.

Both contact cement and wood glue offer distinct advantages depending on the project requirements. To ensure the best results, it’s crucial to match the adhesive to the specific task and material in use. For further guidance, consider reading about other adhesives such as ca glue vs. wood glue.

Contact Cement Application

When applying contact cement, it is essential to understand the types of projects it’s best suited for and learn effective application techniques. Contact cement offers a flexible, permanent, water-resistant, and heat-resistant bond, making it ideal for various use cases.

Contact Cement Uses

Contact cement is versatile and suitable for a range of applications, particularly those involving large surface areas or materials requiring a strong, durable bond. Here are some common uses:

- Metal-to-Metal Bonding: Provides a secure, heat-resistant connection.

- Reattaching Tiles and Sealing Leaks: Ideal for home repair tasks.

- Bonding Veneer: Useful for adhering wood veneers, though care must be taken due to potential movement in the veneer.

- Minor Shoe Repairs: Effective for fixing shoe components.

- Leather-Working: Suitable for bonding leather, offering a flexible yet strong hold.

- Car Interiors: Attaching upholstery or other interior elements.

- Laminate Countertops: Originally designed for adhering high-pressure laminates such as Formica for countertops (Oakwood Veneer).

For further information on whether contact cement is waterproof, refer to our article is contact cement waterproof.

Tips for Applying Contact Cement

To achieve the best results with contact cement, follow these practical tips:

- Surface Preparation: Ensure both surfaces to be bonded are clean, dry, and free from dust or grease. This promotes better adhesion.

- Applying Adhesive: Use a brush or roller to apply an even, thin layer of contact cement to both surfaces. Avoid over-application.

- Allow Solvents to Evaporate: Let the adhesive dry until it becomes tacky to touch. This usually takes around 15-20 minutes depending on the specific product.

- Pressing Surfaces Together: Carefully align and press the surfaces together. Using a laminate or j-roller might not be suitable for all materials, especially flexible sheet veneer. Instead, a veneer scraper is recommended for better surface contact (Oakwood Veneer).

- Pressure Application: Apply firm, even pressure to ensure a strong bond. This can be achieved using hands, clamps, or other pressure tools.

| Step | Action |

|---|---|

| 1 | Prepare surfaces |

| 2 | Apply thin, even layer of cement |

| 3 | Let adhesive dry (15-20 minutes) |

| 4 | Align and press surfaces together |

| 5 | Apply firm pressure |

Understanding these techniques ensures a durable and reliable bond, enhancing the performance of your projects involving contact cement. Explore our guides on shoe goo vs. contact cement and construction adhesive vs. epoxy to compare different adhesive solutions.

Wood Glue vs. Contact Cement

When deciding between wood glue and contact cement for your project, it’s important to understand their differences in terms of strength, durability, and application.

Strength and Durability

Wood Glue:

- Wood glue, specifically PVA (polyvinyl acetate), is designed to create a strong bond with wood by penetrating its fibers. This glue is known for its high tensile strength, making it ideal for woodworking and furniture assembly.

- It provides flexibility and allows for some movement in the wood, accommodating expansion and contraction due to temperature changes.

- Long-term durability is a hallmark of wood glue, making it suitable for load-bearing joints and structural applications.

Contact Cement:

- Contact cement is known for its immediate bonding strength. Once the surfaces are pressed together, they form an almost instant bond with no drying time required.

- The bond is less flexible compared to wood glue, making it less ideal for applications involving solid wood furniture or veneer. It is primarily used for laminates and synthetic materials like Formica.

- Though highly durable for its intended uses, contact cement can fail in environments with high humidity and temperature fluctuations.

| Adhesive Type | Initial Bond Strength | Flexibility | Ideal For |

|---|---|---|---|

| Wood Glue | Moderate | High | Solid wood, furniture, structural joints |

| Contact Cement | High | Low | Laminates, synthetic surfaces |

Differences in Application

Wood Glue:

- Application Method: Apply wood glue to one surface and clamp the pieces together for a strong bond. Clamping is necessary to ensure proper adhesion.

- Flexibility in Positioning: Wood glue allows for adjustments before it sets, giving you time to align the pieces correctly.

- Curing Time: Requires several hours to cure, with full strength achieved in 24 hours. Patience is key for the best results.

- Surface Preparation: Surfaces need to be clean and dry, but not necessarily pre-coated.

Contact Cement:

- Application Method: Apply contact cement to both surfaces and let it dry. Once dry, align carefully and press surfaces firmly together. The bond is immediate and adjustments are not possible (referred to as a ‘launch commit’ attitude).

- Precautions: Due to its instant bond, applying contact cement can be tricky. Precision alignment is crucial as re-positioning is not an option.

- Surface Preparation: Surfaces must be clean, dry, and pre-coated. Both surfaces need two coats for a strong bond—one to seal the wood and another to adhere the pieces together.

- Quick Bonding: Offers immediate bonding with no clamping required, making it suitable for quick projects or those with non-porous materials.

| Adhesive Type | Application Method | Adjustability | Curing Time | Surface Prep |

|---|---|---|---|---|

| Wood Glue | Apply, clamp, align | Yes | Several hours | Clean and dry |

| Contact Cement | Apply to both, let dry, press | No | Immediate | Double coat, pre-treated |

Understanding these distinctions can help you select the right glue for your specific project. For more on contact cement’s suitability in different scenarios, visit our article on is contact cement waterproof. If you need to learn about different adhesives and their uses, check out our comparisons like ca glue vs. wood glue and construction adhesive vs. wood glue.

Using the correct bonding techniques and understanding each adhesive’s strengths can lead to successful and durable projects. For practical considerations and common myths about these adhesives, visit our related articles.

Common Misunderstandings

Myths about Contact Cement

There are several myths surrounding the use of contact cement, many of which can lead to less-than-optimal results if not properly understood.

- Contact Cement for All Veneers:

- Myth: Contact cement is suitable for all types of veneers.

- Reality: Contact cement is not ideal for raw unbacked veneer. It is best suited for synthetic laminates like Formica. For raw wood veneer flitches, using a two-part resin or PVA glue is more appropriate.

- Application with Paint Brush:

- Myth: A paint brush can be used to apply contact cement.

- Reality: Using a paint brush can lead to an uneven and rough surface. It can also result in a spongy glue line, causing a wavy appearance or areas with excessive movement, leading to potential finish issues.

- Instant Use After Application:

- Myth: Contact cement can be used immediately after application.

- Reality: The solvents in contact cement must completely evaporate before applying veneer to the substrate. This prevents pressure bubbles from forming due to solvent off-gassing. Ensure the cement tacks up completely before application (Oakwood Veneer).

Practical Considerations

When using contact cement, there are several practical aspects to keep in mind to ensure successful application and long-lasting adhesion.

- Double-Coating for Wood Surfaces:

- Consideration: All wood surfaces should be two-coated to ensure a secure bond. The first coat should dry thoroughly to seal the wood, followed by another coat before adhering the pieces together (Fine Woodworking Forum).

- Specific Uses for Contact Cement:

- Consideration: Contact cement was originally designed for high-pressure laminates like Formica for countertops and panels. It can be used for backed wood veneer but precautions are necessary due to wood veneers being prone to environmental movement, which can cause failures in the topcoat of catalyzed finishes.

Understanding these myths and practical considerations is essential for choosing the right adhesive for your project. For more information on glue types, check out our sections on is contact cement waterproof, shoe goo vs. contact cement, and construction adhesive vs. wood glue. For further tips on proper application methods, see our articles on proper bonding techniques and maintenance after gluing.

Best Practices

Selecting the Right Glue

Choosing the appropriate glue for your project is essential for achieving strong and durable bonds. Here are some key points to consider:

-

Wood Glue: This adhesive, such as PVA glue, is commonly used in woodworking due to its convenience, ease of application, non-toxicity, and ability to create strong joints in wood. PVA glues are generally preferred for furniture joinery over other adhesives like epoxy and polyurethane glues due to their sufficient strength, easy cleanup, lack of fumes, and cost-effectiveness.

-

Contact Cement: Contact cement is ideal for bonding non-porous surfaces. It is used for applications requiring immediate and solid adhesion. This glue is commonly used for laminates, veneers, and other materials that don’t easily bond with traditional adhesives. For more on the best uses of contact cement, refer to the related section.

Proper Bonding Techniques

Employing the correct bonding techniques ensures the durability and effectiveness of your adhesive work. Here are key practices for both wood glue and contact cement:

Wood Glue

- Surface Preparation: Ensure that the wood surfaces are clean, dry, and free of dust. Smooth, well-prepared surfaces enhance adhesion.

- Even Application: Apply a consistent layer of glue on one or both surfaces. An even spread prevents weak spots and ensures a strong bond.

- Clamping: Secure the glued surfaces using clamps until the adhesive sets. This helps achieve a tight bond and prevents movement while drying.

- Curing Time: Allow the glue to cure fully as per manufacturer’s instructions to ensure maximum bond strength. Typically, this involves waiting a few hours to a day for optimal results.

- For more guidance, check out our article on proper wood glue techniques.

Contact Cement

- Surface Preparation: Both surfaces need to be clean and free of dust and grease. Sanding smooth surfaces lightly can enhance adhesion.

- Application: Apply an even layer of contact cement to both surfaces and let it dry until tacky. This waiting period is crucial for effective bonding.

- Precise Positioning: Once the surfaces are tacky, align and press them together carefully. Contact cement bonds instantly upon touching, allowing no repositioning.

- Pressure: Apply firm and even pressure across the surfaces to ensure that contact cement forms a secure bond.

- For a step-by-step guide, refer to our section on contact cement application tips.

By adhering to these best practices when [selecting the right glue] and employing proper bonding techniques, you can achieve reliable and long-lasting results in your projects. For more information on adhesive comparisons, visit wood glue vs. contact cement.

Final Considerations

Maintenance After Gluing

Maintaining glued surfaces requires careful consideration, especially for specific projects like veneers. Contact cement is not well-suited for use with raw unbacked veneer and is best paired with synthetic laminates like Formica (Oakwood Veneer). For raw wood veneer flitches, users should opt for a two-part resin or PVA glue adhesive instead.

Using a laminate or j-roller is inappropriate for flexible sheet veneer application. Wood veneers are dynamic surfaces that react to the environment by expanding and contracting. Therefore, a rigid glue line is essential to minimize issues that may arise post-finishing. A veneer scraper provides at least sixteen times more surface contact compared to a j-roller (Oakwood Veneer).

Long-Term Adhesion Strength

One of the important factors in the contact cement vs wood glue debate is long-term adhesion strength. Wood glue, typically made of PVA (Polyvinyl Acetate), offers strength sufficient for most applications. It is cheap and easy to use, making it accessible for various projects. However, for those needing stronger adhesives, epoxies and Gorilla Glue are options but come with drawbacks like toxicity, strong fumes, or limited working time.

Tables for comparison:

| Glue Type | Strength | Durability | Cost | Ease of Use |

|---|---|---|---|---|

| Contact Cement | Moderate | High | Moderate | Easy |

| Wood Glue (PVA) | High | Moderate | Low | Very Easy |

| Epoxy | Very High | Very High | High | Moderate |

| Gorilla Glue | Very High | High | High | Moderate |

Choosing between contact cement and wood glue ultimately depends on the specific needs of the project. Maintaining proper techniques and understanding the long-term strengths of each adhesive will ensure successful outcomes. For further assistance on gluing techniques, visit our guide on proper bonding techniques and long-term adhesion.