How Does Contact Adhesive Work? Simple Explanation

Understanding Contact Adhesives

Contact adhesives are a popular choice for a variety of bonding applications due to their unique properties and versatility. This section will explore the distinct attributes and various uses of contact adhesives.

Properties of Contact Adhesives

Contact adhesives are known for their elastomeric characteristics. They are typically applied to both surfaces needing bonding and allowed to dry until tacky before being pressed together. Here are some key properties:

- Mechanical Strength: Contact adhesives create robust mechanical bonds, making them suitable for demanding applications.

- Flexibility: Due to their elastomeric nature, these adhesives provide a flexible bond, accommodating movement and reducing the risk of cracks.

- Ease of Application: They can be applied using brushes, rollers, or sprayers, making them user-friendly for various projects.

- Durability: Once set, contact adhesives offer long-lasting durability and stability, essential for automotive, construction, and aerospace use (Adfast Corp).

Applications of Contact Adhesives

Contact adhesives are utilized in multiple industries due to their strong bonding capabilities and adaptability. Here are some common applications:

- Automotive Industry: Used in sealing and bonding components, contact adhesives are vital for ensuring durable bonds that withstand environmental stresses.

- Construction: Ideal for bonding laminates, countertops, and floorings, contact adhesives provide a strong bond that can endure the stresses of construction activities.

- Aerospace: The flexibility and strength of contact adhesives make them suitable for aerospace applications where reliability and durability are crucial (Adfast Corp).

- OEM (Original Equipment Manufacturer): Extensively used for sealing and coating, contact adhesives ensure stability and robustness in various manufacturing processes.

| Application | Industry | Characteristics |

|---|---|---|

| Sealing & Bonding | Automotive | Durability, Flexibility, Strength |

| Laminates | Construction | Strong Bond, Long-lasting |

| Coating | Aerospace | Reliability, Environmental Resistance |

| Manufacturing | OEM | Stability, Mechanical Strength |

For detailed application instructions and safety tips on using contact adhesives, refer to our additional resources. For a comparison of different adhesive products, check out our insights on E6000 vs. JB Weld and E6000 vs. Super Glue.

Types of Structural Adhesives

Structural adhesives are essential for creating robust bonds between different materials. Here we delve into four prominent types of structural adhesives: epoxy, cyanoacrylate, urethane, and acrylic adhesives.

Epoxy Adhesives

Epoxy adhesives are widely recognized for their strength and durability. These adhesives consist of two parts: a resin and a hardener. When mixed, they undergo a chemical reaction that creates a strong, permanent bond. Epoxies are highly temperature and solvent-resistant (Adfast Corp). They are used in various applications, including automotive, aerospace, and construction industries.

| Properties | Epoxy Adhesives |

|---|---|

| Strength | High |

| Temperature Resistance | Excellent |

| Solvent Resistance | Excellent |

| Common Applications | Automotive, Aerospace, Construction |

For more information on how epoxies compare to other adhesives, visit e6000 vs epoxy.

Cyanoacrylate Adhesives

Commonly known as “super glue,” cyanoacrylate adhesives are fast-setting and form strong bonds with minimal surface preparation. They cure quickly when exposed to moisture, making them ideal for a variety of applications, from bonding small parts in manufacturing to household repairs.

| Properties | Cyanoacrylate Adhesives |

|---|---|

| Strength | Moderate to High |

| Temperature Resistance | Moderate |

| Solvent Resistance | Moderate |

| Setting Time | Rapid (Seconds) |

| Common Applications | Household Repairs, Small Part Bonding |

For a detailed comparison, check b7000 vs. super glue.

Urethane Adhesives

Urethane adhesives are polymer-based and offer high-strength bonding with permanent elasticity. They are particularly noted for their resistance to impact and abrasion. These adhesives are commonly used in applications requiring a durable and flexible bond, such as in the construction and automotive industries (Adfast Corp).

| Properties | Urethane Adhesives |

|---|---|

| Strength | High |

| Elasticity | Excellent |

| Impact Resistance | Excellent |

| Common Applications | Construction, Automotive |

For additional insights, explore construction adhesive vs. caulk.

Acrylic Adhesives

Acrylic adhesives are known for their versatility and high performance, especially in bonding dissimilar materials. They provide excellent resistance to environmental factors such as UV light, making them suitable for outdoor applications. Acrylics offer a good balance of strength and flexibility.

| Properties | Acrylic Adhesives |

|---|---|

| Strength | High |

| Environmental Resistance | Excellent |

| Flexibility | Good |

| Common Applications | Outdoor, Manufacturing, Electronics |

For other adhesive options, see masonry adhesive vs. mortar.

Understanding the specific properties and applications of these structural adhesives can help in selecting the right adhesive for any project. For additional tips on using contact adhesive, read how to use contact adhesive like a pro.

Exploring Thermosetting Adhesives

Thermosetting adhesives are a unique class of adhesives that permanently set upon heating or curing. They are extensively used in various industries due to their outstanding mechanical properties and resistance to heat and chemicals. This section delves into their composition, working mechanism, and the differences between two-part and one-part forms.

Composition and Working Mechanism

Thermosetting adhesives consist of polymer resins that, once cured, create a strong, durable bond between surfaces. These adhesives work through two primary bonding processes: mechanical adhesion and chemical adhesion. Mechanical adhesion involves the adhesive filling micropores on surfaces, creating a strong grip, while chemical adhesion involves molecular-level bonding between the surfaces (Kohesi Bond).

The key to their effectiveness lies in the chemical reactions that occur during the curing process. Upon mixing, the resin and hardener undergo a chemical reaction that forms cross-links, resulting in a rigid, thermoset polymer network. This process ensures the resulting bond is resistant to high temperatures, solvents, and mechanical stress.

| Property | Description |

|---|---|

| Mechanical Adhesion | Fills micropores on surfaces. |

| Chemical Adhesion | Molecular-level bonding. |

| Heat Resistance | High temperature durability. |

| Chemical Resistance | Solvent and chemical durability. |

Two-Part vs. One-Part Form

Two-Part Thermosetting Adhesives

Two-part thermosetting adhesives consist of a resin and a hardener stored separately. When mixed, these components react to form a strong bond. This type offers flexibility in setting times and can be tailored to specific applications by adjusting the ratio of resin to hardener. They are particularly suitable for industrial applications requiring precise control over curing times and mechanical properties.

Some well-known structural adhesives like epoxies and urethanes are typically available in this form. They provide excellent temperature and solvent resistance, making them ideal for high-strength bonding applications (Adfast Corp).

One-Part Thermosetting Adhesives

One-part thermosetting adhesives are pre-mixed and stored at low temperatures to prevent premature curing. These adhesives simplify the application process, as no mixing is required before use. However, they typically have a shorter shelf life and must be stored under specific conditions to maintain their efficacy.

These adhesives are activated by heat, which initiates the curing process. They are convenient and reduce the potential for mixing errors, making them suitable for applications where ease of use and consistent performance are critical.

| Type | Features | Applications |

|---|---|---|

| Two-Part Adhesives | Customizable curing times and properties | Industrial, high-precision applications |

| One-Part Adhesives | Pre-mixed, heat-activated, easy to use | Applications requiring ease and consistency |

Understanding the composition and operation of thermosetting adhesives is crucial for selecting the appropriate type for specific applications. For more information on different adhesives, visit our articles on b7000 vs. super glue and e6000 vs. epoxy.

Unveiling Pressure-Sensitive Adhesives

Pressure-sensitive adhesives (PSAs) are an essential category within the adhesive industry, known for their convenience and ease of use. Here, we will delve into their key characteristics and common applications.

Characteristics of Pressure-Sensitive Adhesives

Pressure-sensitive adhesives are unique in their ability to form a bond under light pressure without the need for solvent, water, or heat to activate the adhesive (Adfast Corp). They work through mechanical adhesion by filling micropores on surfaces to create a strong bond (Kohesi Bond).

Here are some notable characteristics of PSAs:

- Immediate Bond: They form a bond instantly upon the application of light pressure.

- Durability: Ideal for light load applications, they are durable and commonly used for non-structural purposes.

- Surface Versatility: Can bond to a variety of surfaces, including wet or uneven ones.

- Mechanical Flexibility: Offer mechanical strength and flexibility for stable and durable applications.

Common Applications

Due to their versatile nature, pressure-sensitive adhesives are widely used across various industries. Some examples include:

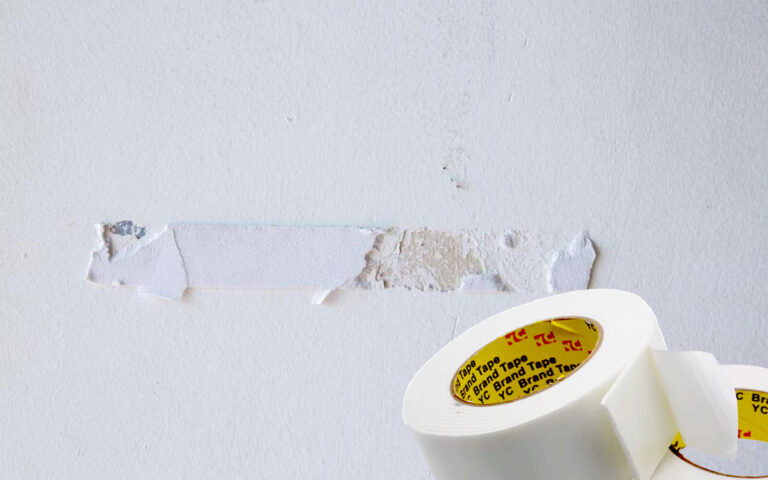

- Tapes: PSAs are frequently used in adhesive tapes, which serve a myriad of purposes from sealing boxes to medical tapes.

- Labels: Commonly utilized in labeling applications, including product labels and barcodes.

- Packaging: Used in packaging materials to ensure secure closure and protection of goods.

- Electronics: Employed to attach components and screens in electronic devices.

- Automotive: PSAs are used for trims and badges in the automotive industry.

Here’s a summary of common applications:

| Application | Examples |

|---|---|

| Tapes | Sealing boxes, medical tapes |

| Labels | Product labels, barcodes |

| Packaging | Secure closures |

| Electronics | Components attachment |

| Automotive | Trims, badges |

For more detailed instructions and tips, visit our comprehensive guides on how to use contact adhesive properly or how to remove adhesive hooks from wall. If you’re comparing different types of adhesives, check out e6000 vs. super glue or e6000 vs jb weld.

Gorilla Contact Adhesive Ultimate

Features and Benefits

Gorilla Contact Adhesive Ultimate is renowned for its impressive strength and permanent bond. Suitable for both indoor and outdoor use, it offers several desirable attributes:

- Strong Bond: Capable of bonding with a variety of materials including metal, glass, fabric, wood, and ceramic.

- Heat Resistance: Withstands temperatures up to 180°F (82°C) (Gorilla Tough).

- Moisture Resistance: Provides some water resistance, making it ideal for outdoor projects.

- Versatile: Can be used on multiple surfaces, ensuring an aggressive tack for strong adhesion.

Application Instructions

Proper application is key to achieving the best results with Gorilla Contact Adhesive Ultimate. Follow these steps for optimal performance:

- Surface Preparation: Ensure surfaces are clean and free of dirt, grease, or oil.

- Application: Apply multiple coats of the adhesive to both surfaces to be joined.

- Dry to Tack: Allow the adhesive to dry to a tack before bonding the surfaces together for maximum strength.

- Bonding: Press the surfaces together firmly and hold.

For more tips on adhering to best practices, reference our article on how to use contact adhesive properly.

Temperature and Moisture Resistance

Understanding the temperature and moisture ratings is crucial when using this adhesive:

- Application Temperature: Between 50°F (10°C) and 90°F (32°C) (Gorilla Tough).

- Service Temperature: From 32°F (0°C) to 180°F (82°C).

- Moisture Resistance: Designed to withstand exposure to moisture, ensuring longevity in outdoor applications.

It’s worth noting that certain materials such as polystyrene foam and unsupported vinyl are not recommended for use with this adhesive. Additionally, specific plastics may experience bond failures due to plasticizer migration (Gorilla Tough).

If you need to understand how this product compares with other adhesives, our articles like b7000 vs. t7000 vs. e8000 and e6000 vs jb weld might offer valuable insights. For more advice on handling adhesives, you might also check how to use construction adhesive without gun.

Safety Tips and Best Practices

Understanding and following safety guidelines when using contact adhesives is crucial for ensuring effective results and avoiding potential hazards.

Material Compatibility

Contact adhesives are versatile and bond well with a variety of materials. However, it’s essential to ensure compatibility to avoid issues with adhesion or damage to the material. The following table shows common materials and their compatibility with contact adhesives.

| Material | Compatibility |

|---|---|

| Wood | High |

| Metal | High |

| Plastic | Medium |

| Glass | Medium |

| Fabric | Low |

Before application, testing the adhesive on a small, inconspicuous area is recommended to ensure it won’t cause damage or discoloration.

Precautions while Using Contact Adhesives

Using contact adhesives in a safe manner helps prevent injuries and ensures the best results. Consider these precautions:

- Ventilation: Use contact adhesives in well-ventilated areas to avoid inhaling harmful fumes. Working outdoors or in a space with good airflow is ideal.

- Protective Gear: Wear gloves and safety goggles to protect your skin and eyes. This is especially important since contact adhesives can cause irritation or burns.

- Temperature Management: As contact adhesives can be used in a molten state at high temperatures (Glue Guns Direct), ensure appropriate handling to avoid burns.

- Application: Apply the adhesive evenly on both surfaces that need to be bonded. Let it sit until the adhesive becomes tacky before pressing the surfaces together to ensure a strong bond (Adfast Corp).

For detailed instructions on how to use contact adhesive properly, visit our article on how to use contact adhesive properly.

Removal of Adhesive Residues

Safely removing adhesive residues can prevent surface damage. Here’s how to handle common surfaces:

- General Surfaces: Use a mixture of warm water and mild soap. Apply it to the residue and gently scrub with a soft cloth.

- Plastic and Metal: For stubborn residues, consider using rubbing alcohol or acetone. Apply a small amount to a cloth and rub the adhesive.

- Fabric: Place a paper towel over the adhesive and iron it on a low setting. The heat will transfer the adhesive to the paper towel.

For specialized methods on removing adhesive from specific surfaces, check out these articles:

- how to remove adhesive from aluminum

- how to remove adhesive residue from vinyl

- how to remove adhesive from glass mirror

- how to remove windshield adhesive without damage

By following these tips and best practices, individuals can ensure safe and efficient use of contact adhesives in various applications.