Is JB Weld Gas Resistant? Expert Analysis

Understanding JB Weld

What is JB Weld?

JB Weld is a versatile adhesive product known for its strong bonding capabilities. It is primarily used for repairing various materials and surfaces, offering a reliable solution for both household and industrial applications. JB Weld is a two-part epoxy system that involves a resin and a hardener. When these two components are mixed together, they undergo a chemical reaction that creates a solid and durable bond.

Properties of JB Weld

JB Weld is admired for its numerous properties that make it a go-to choice for many repair needs. Here are some key characteristics of JB Weld:

- Chemical and Petroleum Resistance: JB Weld epoxy is resistant to chemicals, petroleum, acids, and water. It is often used in environments where exposure to these substances is a concern.

- Temperature Resistance: JB Weld can withstand high temperatures up to 500°F (260°C) consistently and up to 600°F (316°C) for short periods (Wikipedia).

- Shock and Vibration Resistance: Once cured, JB Weld resists shock, vibration, and temperature fluctuations, ensuring a long-lasting repair.

- Versatility in Use: The product can be used on a variety of surfaces, including metal, wood, plastic, and ceramics. For more information on applications, visit is jb weld fuel resistant.

- Strength and Durability: JB Weld forms a strong and durable bond capable of holding up under pressure, providing reliable performance even under demanding conditions.

| Property | Value |

|---|---|

| Chemical Resistance | High |

| Temperature Resistance | Up to 500°F (260°C) continuously; 600°F (316°C) for short periods |

| Shock Resistance | Yes |

| Vibration Resistance | Yes |

| Versatility | High |

For those considering whether JB Weld is gas resistant, it is suitable for gasoline tank repairs and can withstand continuous exposure to fuel when submerged (Bushcraft USA).

Understanding these properties helps in making informed choices about where JB Weld can be effectively used. For a deeper dive into the comparison of adhesives, check out our articles on construction adhesive vs. epoxy and other related topics.

Explore more about JB Weld in the sections on its applications and performance features like heat resistance.

Versatility of JB Weld

JB Weld products are known for their versatility and effectiveness across a wide range of applications and surfaces. This section delves into the diverse uses and compatibility of JB Weld.

Applications of JB Weld

JB Weld epoxy is a two-part adhesive revered for its robust bonding capability. Here are some common applications:

- Automotive Repairs: JB Weld is often used for repairing engine blocks, radiators, and other automotive components.

- Plumbing: It can fix leaks in pipes and other plumbing issues.

- Household Repairs: From mending broken ceramics to fixing wooden furniture, JB Weld is a go-to for many household repairs.

- Electrical Applications: It’s apt for insulating and securing electrical connections.

- Crafts and DIY Projects: Ideal for bonding various materials in crafting projects.

For those interested in the chemical resistance of JB Weld, check out our article on is jb weld fuel resistant.

Surfaces JB Weld Bonds

JB Weld epoxy is renowned for its capacity to bond a multitude of surfaces. Below is a table summarizing the materials compatible with JB Weld products:

| Material | Compatibility |

|---|---|

| Metal | Yes |

| Porcelain | Yes |

| Ceramic | Yes |

| Glass | Yes |

| Wood | Yes |

| Fabric | Yes |

| Plastic | Yes |

| Concrete | Yes |

| Fiberglass | Yes |

(Source: Wikipedia)

JB Weld can be particularly effective on metal surfaces. It is widely used for bonding metals like iron, steel, copper, aluminum, brass, and bronze. For more information on bonding materials, visit our comparison articles such as construction adhesive vs. epoxy and ca glue vs. wood glue.

Summary of Key Properties and Features

JB Weld products, including J-B Kwik and ClearWeld epoxy, share several advantageous properties:

- Waterproof: Suitable for underwater and wet-surface applications.

- Chemical Resistance: Withstands exposure to petroleum, chemicals, and acids.

- Heat Resistance: Can endure extreme temperature fluctuations.

- Machinable: Cured JB Weld can be drilled, formed, ground, tapped, machined, sanded, and painted.

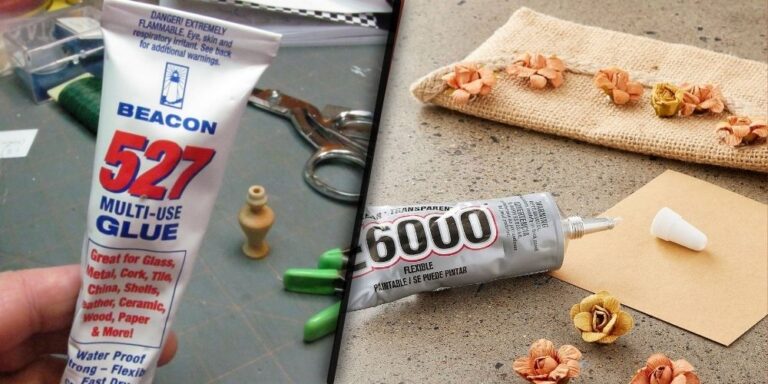

For those exploring various adhesives, consider reviewing our articles such as shoe goo vs. contact cement and liquid nails vs. e6000.

By understanding the versatility of JB Weld, individuals can make informed decisions about its application and suitability for their specific glue-related needs.

Different JB Weld Products

Exploring the various products offered by JB Weld can help determine which is best suited for your needs, particularly when it comes to applications that require gas resistance.

SuperWeld™ Instant Adhesive

The SuperWeld™ Instant Adhesive by J-B Weld is a specifically formulated cyanoacrylate super glue that offers a robust, immediate bond. It is designed to work efficiently on a variety of surfaces, including those that are typically difficult to bond.

SuperWeld™ Instant Adhesive’s quick-setting nature makes it an ideal choice for projects requiring speed and precision. The adhesive sets in seconds, which can be beneficial for those in need of a rapid fix. This product is often used for bonding materials such as:

- Metal

- Plastic

- Rubber

- Ceramic

- Wood

Given its versatile application and strong adhesive properties, SuperWeld™ is a reliable option for various repair projects.

MinuteWeld™ Syringe

The MinuteWeld™ Syringe by J-B Weld offers a unique two-part epoxy solution that provides robust bonding properties with a strength of 2300 PSI. One of the key features of MinuteWeld™ is its rapid setting time; it sets in just 1 minute and cures in 1 hour, delivering a clear and durable finish.

In addition to its quick-setting properties, MinuteWeld™ Syringe is designed for precision, thanks to its easy-to-use syringe applicator. This allows for controlled, even application, which is particularly useful for detailed work.

Key specifications:

| Property | MinuteWeld™ Syringe Specifications |

|---|---|

| Strength | 2300 PSI |

| Set Time | 1 minute |

| Cure Time | 1 hour |

| Bonding | Clear, durable bond |

JB Weld products like the SuperWeld™ Instant Adhesive and MinuteWeld™ Syringe are available for various uses, making them suitable choices for a wide range of projects. For more information on adhesive products, check out our articles on is jb weld fuel resistant and is jb weld waterproof.

Performance of JB Weld

The performance characteristics of JB Weld are crucial for understanding its capabilities in various applications. This section will explore the strength, quick setting, heat, and chemical resistance of JB Weld.

Strength and Quick Setting

JB Weld is renowned for its impressive strength and quick-setting properties. When mixed and applied correctly, JB Weld epoxy forms a robust bond capable of withstanding significant stress and strain. The product specifications are as follows:

| Property | Value |

|---|---|

| Tensile Strength | 5020 PSI |

| Set Time | 4-6 hours |

| Cure Time | 15-24 hours |

JB Weld’s strength is such that when fully cured, the bond can be drilled, formed, ground, tapped, machined, sanded, and painted (Wikipedia). Users looking for a quicker set time might consider J-B Kwik, a variant that sets in just 6 minutes.

Heat and Chemical Resistance

JB Weld is specifically formulated to resist high temperatures and a variety of chemicals. This makes it ideal for demanding environments that experience extreme conditions.

| Property | Value |

|---|---|

| Maximum Constant Temperature | 500°F (260°C) |

| Maximum Short-Term Temperature | 600°F (316°C) |

| Acid Resistance | Yes |

| Water Resistance | Yes |

| Petroleum/Chemical Resistance | Yes |

JB Weld can withstand temperatures up to 500°F (260°C) constantly and up to 600°F (316°C) for shorter periods (Wikipedia). This heat resistance ensures durability and reliability in applications that involve significant temperature fluctuations, such as automotive repairs and industrial settings.

The chemical resistance of JB Weld is equally noteworthy. It is petroleum/chemical-resistant and acid-resistant, making it suitable for use in environments where exposure to corrosive substances is possible. This includes applications involving gasoline and other fuels, which are common queries for users wanting to know is JB Weld fuel resistant.

By understanding the robust performance characteristics of JB Weld, users can make informed decisions regarding its suitability for their specific needs. Whether dealing with high temperatures, chemical exposures, or seeking a strong bond, JB Weld offers a dependable solution. For related comparisons, explore our articles on construction adhesive vs. epoxy and structural adhesive vs. welding, or check out products like loctite 620 vs. 680.

Gas Resistance of JB Weld

When considering glue for gas-related repairs, one might wonder, “Is JB Weld gas resistant?” This section delves into the gas resistance of JB Weld, focusing on its efficacy in repairing gasoline tanks and sharing user experiences.

Gasoline Tank Repairs

JB Weld is indeed gas resistant and can be used to repair gas tank leaks (Bushcraft USA). However, not all scenarios yield the same results. It’s crucial to understand the details for optimal outcomes:

| Situation | Recommendation | Source |

|---|---|---|

| Repair submerged in gasoline | Effective | Bushcraft USA |

| Repair above fuel level | May degrade due to fumes | Quora |

| For minor rust-induced leaks | Effective when applied with proper cleaning | Quora |

The repair process is vital for effectiveness:

- Clean the area thoroughly using sandpaper and rubbing alcohol.

- Ensure the area is shiny before applying JB Weld.

- Apply JB Weld generously on the area.

- For minor leaks, driving a self-tapping screw can enhance the repair.

User Experiences with Gasoline Tanks

User testimonials and experiences provide invaluable insight into the real-world application of JB Weld for gasoline tank repairs. One user successfully sealed a significant rip in a gasoline tank by meticulously cleaning the affected area before applying JB Weld.

Another user found success in addressing minor leaks caused by rust. The process involved thorough cleaning until the surface was shiny, followed by applying JB Weld generously and driving in a self-tapping screw to ensure a secure and leak-proof seal.

It’s crucial to note that JB Weld is more effective when the repair remains totally submerged in fuel. Gasoline fumes were observed to degrade JB Weld when the repair was above the level of fuel in the tank (Quora).

If you are dealing with a repair that involves exposure to gasoline fumes, consider using alternative products like Marine-Tex for a more durable solution (Quora).

For more information on different adhesives and their properties, visit our articles on is jb weld fuel resistant, is jb weld oil resistant, and construction adhesive vs. epoxy.