What Adhesive to Use to Attach Sink to Vanity: Guide

Types of Glue for Vanity Installation

Selecting the right adhesive to attach a sink to a vanity is crucial for ensuring a secure and durable installation. There are several types of glues available, each with unique properties and advantages. This section will cover polyurethane adhesives, contact cement, and epoxy resin.

Polyurethane Adhesives

Polyurethane adhesives are highly recommended for vanity installations due to their strong, flexible, and waterproof nature. These adhesives are also heat and cold resistant, making them ideal for bathroom environments where temperature and moisture levels can vary. According to MTD Vanities, polyurethane adhesives offer optimal performance when it comes to attaching vanity tops.

Key Attributes of Polyurethane Adhesives:

- Strong bond

- Flexible

- Waterproof

- Heat and cold resistant

Contact Cement

Contact cement is another effective adhesive option for attaching bathroom vanity tops. Known for its strength and water resistance, contact cement creates a permanent bond, making it suitable for environments exposed to moisture. However, it requires careful application following the manufacturer’s instructions and should be used in a well-ventilated area for best results.

According to MTD Vanities, contact cement ensures a reliable and durable bond.

Key Attributes of Contact Cement:

- Strong bond

- Water-resistant

- Permanent adhesion

Epoxy Resin

Epoxy resin is highlighted as one of the best adhesive options for installing a bathroom vanity top. Its strength, durability, and ability to bond well to both porous and non-porous surfaces make it an excellent choice. Epoxy resin adhesives are known for creating long-lasting installations that withstand the test of time and varying bathroom conditions.

Key Attributes of Epoxy Resin:

- Extremely strong bond

- Durable

- Bonds well to various surfaces

| Adhesive Type | Strength | Water Resistance | Flexibility | Temperature Resistance |

|---|---|---|---|---|

| Polyurethane Adhesives | High | High | Flexible | High |

| Contact Cement | High | High | Moderate | Moderate |

| Epoxy Resin | Very High | Moderate | Rigid | High |

For further insights into adhesives and their use, explore related topics like how to glue sink to vanity, what adhesive sticks to ceramic tile, and what adhesive sticks to glass.

Best Glue for Attaching Sink to Vanity

Selecting the appropriate adhesive to attach a sink to a vanity is crucial for ensuring a secure, long-lasting installation. Key options include silicone adhesive, epoxy resin adhesives, and two-part epoxy.

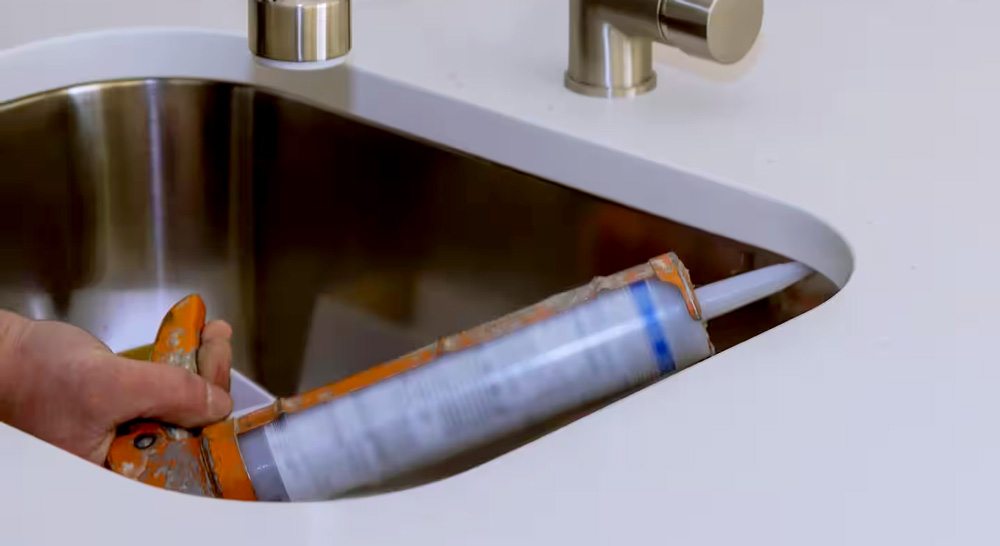

Silicone Adhesive

Silicone adhesive is widely used for attaching sinks to vanities due to its waterproof, flexible, and robust properties. It is also mold- and mildew-resistant, making it ideal for wet environments. Suitable for various surfaces such as natural stone, porcelain, ceramic, acrylic, and metals, silicone adhesive offers versatility and reliability.

| Attribute | Description |

|---|---|

| Waterproof | Yes |

| Flexibility | High |

| Suitable Surfaces | Natural stone, porcelain, ceramic, acrylic, metals |

| Drying Time | 30 minutes |

| Curing Time | 24 hours |

| Mold Resistance | Yes |

For additional information, see our comparison on dap vs. ge silicone and learn about what adhesive sticks to silicone.

Epoxy Resin Adhesives

Epoxy resin adhesives are especially effective for natural stones like granite and marble. They provide strong adhesion and are moisture- and chemical-resistant but lack the flexibility of silicone adhesives. Epoxy resin is ideal for ensuring a durable bond in more demanding applications.

| Attribute | Description |

|---|---|

| Waterproof | Yes |

| Flexibility | Low |

| Suitable Surfaces | Natural stone, epoxy resin sinks |

| Drying Time | 45-60 minutes |

| Curing Time | 24 hours |

| Chemical Resistance | Yes |

Explore more about adhesive properties by checking out our articles on how strong is jb weld and does e6000 work on plastic.

Two-Part Epoxy

Two-part epoxy consists of a resin and a hardener, offering heavy-duty and permanent adhesion that is moisture- and chemical-resistant. This type of adhesive is suitable for materials such as wood or metal and ensures robust bonding for more demanding projects.

| Attribute | Description |

|---|---|

| Waterproof | Yes |

| Flexibility | Low |

| Suitable Surfaces | Wood, metal |

| Drying Time | 45 minutes |

| Curing Time | 24 hours |

| Chemical Resistance | Yes |

To see how different adhesives compare for various applications, check out how to glue sink to vanity and what adhesive sticks to glass.

Understanding these adhesive options helps you make an informed decision for your project, ensuring a secure and lasting bond. For other adhesive comparisons, you might also be interested in gutter sealant vs. silicone and shoe goo vs. goop.

Factors Influencing Glue Choice

Choosing the appropriate adhesive for attaching a sink to a vanity depends on several factors, primarily the materials of the vanity and the sink. Each type of material interacts differently with various adhesives, impacting the strength and durability of the bond.

Vanity Material

The material of the vanity plays a crucial role in determining the best adhesive to use. Here are some common vanity materials and suitable adhesives:

| Vanity Material | Recommended Adhesive | Reasons |

|---|---|---|

| Wood | Polyurethane Adhesives | Strong, flexible, waterproof, and resistant to temperature extremes (MTD Vanities) |

| Particle Board | Contact Cement | Provides a strong bond without penetrating the surface too deeply |

| Natural Stone | Epoxy Resin | Exceptional strength, durable bond to porous surfaces like granite and marble (MTD Vanities) |

| Laminate | Silicone Adhesive | Excellent waterproof properties, flexibility, and durability (Angi) |

For wooden vanities, high-quality wood glue like Titebond II is also a strong choice due to its excellent holding power and resistance to bathroom moisture and humidity (MTD Vanities).

Sink Material

The material of the sink is another critical factor in adhesive selection. Different materials require adhesives that can create a strong, lasting bond:

| Sink Material | Recommended Adhesive | Reasons |

|---|---|---|

| Porcelain | Silicone Adhesive | Waterproof, flexible, mold- and mildew-resistant, strong bond on smooth surfaces (Angi) |

| Stainless Steel | Epoxy Resin | Strong adhesion, moisture, and chemical-resistant, suitable for non-porous surfaces (Angi) |

| Natural Stone | Epoxy Resin | Strong bond on porous surfaces like granite and marble, durable (MTD Vanities) |

| Acrylic | Silicone Adhesive | Excellent flexibility and waterproof properties, prevents leaks (Angi) |

Silicone adhesive is often the most versatile and commonly used option due to its ability to bond with a variety of sink materials, including natural stone, porcelain, ceramic, acrylic, and metals. It is waterproof, flexible, strong, mold- and mildew-resistant, and cures completely in 24 hours (Angi).

Selecting the right adhesive ensures a secure and long-lasting installation. For those seeking further guidance on the use of adhesives in different scenarios, explore related topics like what can I use instead of spray adhesive and how strong is JB Weld.

Differences Between Vessel and Undermount Sinks

Understanding the differences between vessel and undermount sinks is crucial when deciding the best option for your vanity installation. These two popular choices offer distinct aesthetics, installation methods, and functional advantages.

Vessel Sinks Overview

Vessel sinks sit on top of the bathroom counter or vanity, providing a striking visual appeal. They come in various colors, sizes, and shapes, allowing for greater customization (Allied Plumbing & Heating Supply Co.). Common materials include glass and ceramic, which are usually more affordable and readily available, making vessel sinks a budget-friendly option.

Key Features of Vessel Sinks

- Aesthetics: Offers unique, stylish designs.

- Affordability: Generally more affordable due to the materials used.

- Ease of Installation: Sits on top of the counter, requiring less modification to the countertop.

- Counter Space: Maintains ample counter space around the sink.

Undermount Sinks Overview

Undermount sinks are installed beneath the countertop, creating a seamless and cohesive look. This installation method is ideal for achieving a modern and sleek design in your bathroom (Allied Plumbing & Heating Supply Co.). Undermount sinks are typically made from more durable materials such as stainless steel, quartz, or fireclay.

Key Features of Undermount Sinks

- Aesthetics: Offers a seamless blend with the counter.

- Durability: Made from robust materials, ensuring longevity.

- Ease of Cleaning: The lack of a raised edge makes cleaning the countertop simpler.

- Countertop Requirement: Requires a sturdier countertop to support the sink’s weight.

| Feature | Vessel Sinks | Undermount Sinks |

|---|---|---|

| Installation | Sits on top of the counter | Underneath the counter |

| Cost | More affordable | More expensive |

| Aesthetic Options | Various colors, sizes, and shapes | Seamless look with fewer design options |

| Installation Complexity | Simple | More complex |

| Materials | Glass, Ceramic | Stainless Steel, Quartz, Fireclay |

Choosing between a vessel and an undermount sink often depends on personal preferences, the vanity material, and the overall bathroom design. For more information on the materials used for bathroom vanity tops, visit Robern’s guide. Understanding these differences helps in making an informed choice, ensuring your sink complements both the functionality and aesthetics of your bathroom.

For additional insights on adhesives and their application, explore our topics on what adhesive sticks to ceramic tile and how to glue a sink to vanity.

Popular Kitchen Sink Materials

Choosing the right sink material is crucial for both functionality and aesthetics. In this section, we examine three popular types of kitchen sinks: stainless steel, enameled cast iron, and quartz composite.

Stainless Steel Sinks

Stainless steel sinks are a popular choice for their affordability and ease of maintenance. They blend seamlessly with various countertop materials and kitchen styles. However, they come with some caveats:

-

Pros:

-

Affordable

-

Easy to clean

-

Versatile

-

Cons:

-

Prone to water spots

-

Can be noisy during dishwashing

-

Susceptible to scratching

For more details on these sinks, visit 4Front Energy.

Enameled Cast Iron Sinks

Enameled cast iron sinks are celebrated for their durability and aesthetic appeal. They have a non-porous enamel coating and come in various finishes:

-

Pros:

-

Highly durable

-

Available in various colors and finishes

-

Non-porous surface

-

Cons:

-

Heavy

-

Susceptible to chipping and scratching

-

Potential for rust if enamel is chipped

For a more detailed overview, check Vevano.

Quartz Composite Sinks

Quartz composite sinks are known for their extreme durability and aesthetic value. Made from a blend of quartz and resin, these sinks offer several benefits:

-

Pros:

-

Heat resistant

-

Sound resistant

-

Non-porous

-

Resistant to chips and scratches

-

Cons:

-

Delicate items can break if dropped in the sink

For further reading, visit Vevano.

To learn more about adhesives related to these sink materials, check our article on how to glue sink to vanity. For additional tips on selecting adhesives, explore what adhesive sticks to glass and what adhesive sticks to ceramic tile.

Durable Sink Material Options

Choosing the right sink material is crucial for ensuring durability and longevity. Here are three excellent options for durable sink materials: Quartz Composite Sinks, Granite Composite Sinks, and Fireclay Sinks.

Quartz Composite Sinks

Quartz composite sinks, made of quartz dust and acrylic resin, are known for their durability and resistance to common kitchen hazards. These sinks are non-porous, making them resistant to stains, heat, and chips. According to 4Front Energy, quartz composite sinks have a lifespan of 40-50 years and are available in a variety of colors to match different kitchen styles.

Key Features:

- Non-porous: Resistant to stains and bacteria

- Heat resistant: Can handle high temperatures without damage

- Chip resistant: Durable and less prone to damage

- Variety of colors: Matches various kitchen styles

| Feature | Quartz Composite Sinks |

|---|---|

| Lifespan | 40-50 years |

| Heat Resistance | High |

| Stain Resistance | Excellent |

| Color Options | Multiple |

| Durability | High |

Granite Composite Sinks

Granite composite sinks are another highly durable option for kitchen sinks. These sinks are created from a blend of granite stone dust and acrylic resins. Granite composite sinks are easy to clean, maintain, and are resistant to heat, scratches, chips, and staining (Vevano).

Key Features:

- Heat resistant: Can withstand hot pots and pans

- Scratch resistant: Durable surface that resists scratches

- Sound dampening: Less noise when washing dishes

- Easy to clean: Low maintenance

| Feature | Granite Composite Sinks |

|---|---|

| Lifespan | Long |

| Heat Resistance | High |

| Scratch Resistance | Excellent |

| Sound Dampening | Yes |

| Maintenance | Low |

Fireclay Sinks

Fireclay sinks are a popular choice for their durability and aesthetic appeal, often seen in white farmhouse styles. Made from molded ceramic clay that is fired at high temperatures, these sinks are extremely hard, durable, and easy to clean. Fireclay sinks are long-lasting but may require professional installation due to their heavy weight (4Front Energy).

Key Features:

- Durable: Resistant to chips and scratches

- Heat resistant: Withstands high temperatures

- Aesthetic appeal: Classic look, predominantly in white

- Low maintenance: Easy to clean surface

| Feature | Fireclay Sinks |

|---|---|

| Lifespan | Long |

| Heat Resistance | High |

| Color Options | Limited (White/Off-White) |

| Installation | Requires professional |

| Aesthetic | Classic/Farmhouse |

These materials provide various advantages for those looking to install or upgrade their kitchen sinks. For guidance on the right adhesive to attach sinks to vanities, check out our section on how to glue sink to vanity.