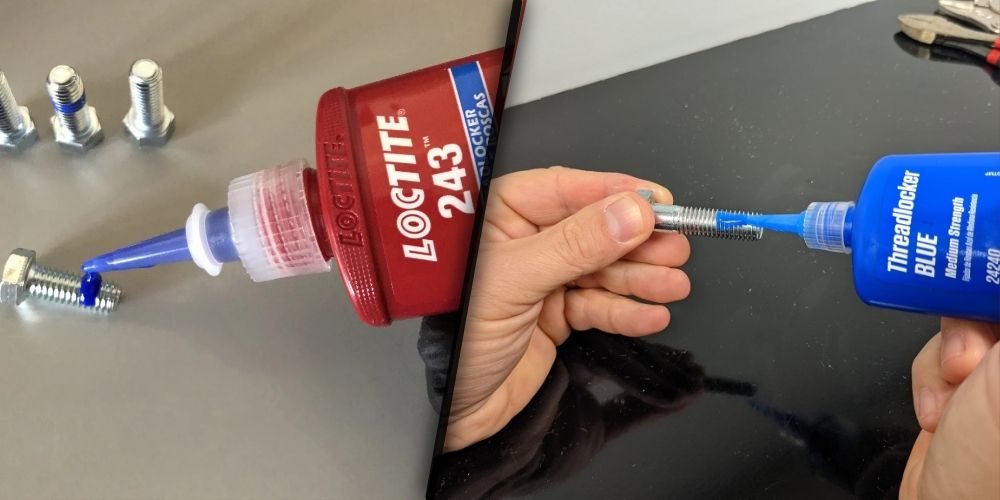

Loctite Blue vs. Permatex Blue: Threadlocker Showdown

Loctite Blue Threadlocker (242)

Versatility and Applications

Loctite Blue Threadlocker (242) is a versatile adhesive designed for a variety of applications. It’s particularly suitable for motorized and nonmotorized parts that need occasional servicing. This includes automotive parts, motorized yard equipment, bicycles, and furniture. Its ease of use and robust performance make it a preferred choice among manufacturers and DIY enthusiasts alike.

| Application | Examples |

|---|---|

| Automotive | Car parts, bolts, screws |

| Motorized equipment | Lawn mowers, chainsaws |

| Bicycles | Chains, gears |

| Furniture | Shelves, tables, chairs |

Strength and Removability

Loctite Blue 242 is designed to provide a medium-strength bond that can be easily removed with common hand tools, making it ideal for parts that require regular maintenance or replacement. In contrast, Loctite Red is a high-strength threadlocker that requires heating to 500°F for removal, making it more suitable for permanent fixes (Loctite).

| Threadlocker Type | Strength | Removability |

|---|---|---|

| Loctite Blue 242 | Medium | Hand tools |

| Loctite Red | High | Heating to 500°F |

This medium-strength feature of Loctite Blue 242 ensures a reliable hold while allowing for easy disassembly when necessary. Whether you’re working on motorized equipment or simply fixing a piece of furniture, Loctite Blue 242 provides the balance of strength and convenience you need.

Discover more comparisons with articles on loctite 242 vs. 243 and loctite 242 vs. 271. These help to understand the detailed differences and ideal use cases for different Loctite products. For tips on choosing the right adhesive for specific needs, visit loctite blue vs. permatex blue.

Loctite Blue vs. Loctite Red

Loctite offers a range of threadlockers, with Loctite Blue (242) and Loctite Red being among the most popular. It is vital to understand their differences in usage and removal processes to select the right product for your needs.

Differences in Usage

Loctite Blue (242) is designed for applications where removable strength is required. It is suitable for parts that might require servicing, such as car parts, motorized yard equipment, bicycles, and furniture (Loctite Products). Loctite Blue provides a medium-strength bond that can be disassembled using common hand tools, making it highly versatile.

| Feature | Loctite Blue (242) | Loctite Red |

|---|---|---|

| Bond Strength | Medium | High |

| Typical Applications | Motorized and nonmotorized parts requiring occasional disassembly | Parts where a permanent fix is desired |

| Removal | Common tools | Heat up to 500°F |

In contrast, Loctite Red is engineered for permanent applications. It offers high strength and is ideal for parts that should not be easily tampered with. Due to its permanent nature, it is not suitable for components that require frequent adjustments.

Removal Processes

The removal process of Loctite Blue and Loctite Red threadlockers highlights one of their most significant differences. Loctite Blue (242) can be easily removed using common hand tools. This feature makes it convenient for applications that may require disassembly or servicing (Loctite).

| Threadlocker Type | Removal Method |

|---|---|

| Loctite Blue (242) | Common hand tools |

| Loctite Red | Heat to 500°F, then tools |

On the other hand, Loctite Red requires a more rigorous removal process. The bonded parts need to be heated to approximately 500°F to weaken the adhesive. Once heated, they can then be disassembled using appropriate tools. This makes Loctite Red a suitable option for permanent solutions but less ideal for parts that may need future adjustments.

When choosing between Loctite Blue and Loctite Red threadlockers, it is crucial to consider your application’s specific requirements. For more comparisons, check out our detailed articles on loctite 242 vs. 271 and loctite 262 vs. 272.

Permatex Ultra Copper Silicone

Permatex Ultra Copper Silicone is a high-performance RTV (Room Temperature Vulcanizing) silicone that offers multiple benefits for various applications. Let’s examine its composition, features, and suitable uses.

Composition and Features

Permatex® Ultra Copper® Maximum Temperature RTV Silicone is known for its distinctive copper color. Despite its appearance, it contains no copper or other metals and is not electrically conductive (Permatex FAQs). The unique formulation ensures high temperature resistance, making it an ideal choice for applications where heat stability is crucial.

Key Features:

- High Temperature Resistance: Can withstand temperatures ranging from -65°F to 700°F (-54°C to 371°C) intermittently.

- Durability: Resists aging, weathering, and thermal cycling without hardening or cracking.

- Non-Corrosive: Safe for use on oxygen sensor-equipped vehicles and other metal surfaces.

- Non-Conductive: Safe for electronic components as it does not conduct electricity.

Suitable Applications

Permatex Ultra Copper Silicone is versatile and suitable for a wide range of applications, especially those involving high temperatures. Below are some examples of where this product excels.

Ideal Uses:

- Automotive: Perfect for high-temperature applications such as sealing exhaust manifolds, valve covers, timing chain covers, and high-performance engines.

- Industrial: Suitable for sealing and bonding metal, glass, ceramic, paper, wood, and plastic in high-temperature environments.

- Electrical: Safe for electronic components due to its non-conductive nature, making it suitable for use in electrical enclosures and wiring.

| Suitable Applications | Temperature Range | Resistance |

|---|---|---|

| Exhaust Manifolds | -65°F to 700°F | High Temperature |

| Valve Covers | -65°F to 700°F | Thermal Cycling |

| Timing Chain Covers | -65°F to 700°F | Aging & Weather |

| High-Performance Engines | -65°F to 700°F | Non-Corrosive |

| Electrical Components | Safe | Non-Conductive |

For more comprehensive guidelines on choosing the correct sealant or adhesive for your needs, refer to our Permatex Guidelines and Recommendations section.

By understanding the composition and suitable applications of Permatex Ultra Copper Silicone, you can make an informed decision when choosing between this and other performance sealants. For further comparisons, you might be interested in our articles on leak lock vs. loctite as well as loctite 515 vs. loctite 518.

Permatex RTV Silicone Options

For those comparing different types of glue, especially threadlockers and sealants, understanding Permatex’s RTV (Room Temperature Vulcanizing) silicone options is crucial. These products offer a wide range of applications and benefits suited for various mechanical and sealing needs.

OPTIMUM BLACK Gasket Maker

Permatex’s OPTIMUM BLACK gasket maker is specifically designed for newer, lightweight, and premium components. This product is highly recommended where maximum oil resistance is required, particularly in assemblies where dissimilar materials need to be joined. According to Permatex FAQs, the OPTIMUM BLACK gasket maker offers unparalleled oil resistance, making it ideal for modern vehicles and machinery.

Key Features:

- High oil resistance

- Suitable for lightweight and premium components

- Effective on assemblies with different materials

| Feature | Specification |

|---|---|

| Oil Resistance | Maximum |

| Component Compatibility | Lightweight, Premium |

| Material Compatibility | Dissimilar Materials |

RTV Silicone Variants

Permatex provides a range of RTV silicone variants, each color-coded to indicate its specific applications and strengths. These variants include Ultra Blue, Ultra Copper, and Ultra Grey, each tailored for different uses.

Ultra Blue® RTV Silicone

Ultra Blue is a medium strength product not recommended for gasoline environments. It’s versatile for general gasket sealing.

- Medium Strength

- Not for gasoline exposure

Ultra Copper® RTV Silicone

Ultra Copper stands out as a maximum temperature RTV silicone. It is copper in color but does not contain metal or conduct electricity. Best for applications requiring high-temperature resistance.

- Maximum Temperature Resistance

- Non-conductive

| Variant | Strength | Temperature Resistance | Notable Feature |

|---|---|---|---|

| Ultra Blue® | Medium | Medium | Versatile use |

| Ultra Copper® | High | Maximum | High temp, non-conductive |

| Ultra Grey® | High | High | High torque, high vibration |

Ultra Grey® RTV Silicone

Ultra Grey is designed for high torque, high vibration, and high-temperature resistance applications, making it ideal for demanding mechanical environments.

- High Torque

- High Vibration

- High Temperature Resistance

Selecting the right RTV silicone is essential for the effectiveness and longevity of the sealed joints. For alternate products and more detailed comparisons, explore our other articles on leak lock vs. loctite and loctite 221 vs. 222. Always consult product guidelines and recommendations to ensure optimal performance.

Permatex Guidelines and Recommendations

To effectively use Permatex products, it’s important to understand their guidelines and recommendations. This section delves into product usage advice and the color-coded system that aids in selecting the proper product for specific applications.

Product Usage Advice

Permatex offers a wide range of RTV silicone products, each formulated for particular uses. It’s crucial to follow the manufacturer’s instructions for optimal results. For instance, the Permatex® Ultra Copper® Maximum Temperature RTV Silicone is a silicone product that is copper in color but does not contain any copper or other metal; it is not electrically conductive.

Permatex advises against altering their RTV silicone products by adding any solvents, chemicals, or fillers, as this can alter the product’s formula and compromise its performance. For specific needs, contact the Permatex Tech Center to get guidance on selecting another suitable product (Permatex FAQs).

Color-Coded System

Permatex simplifies product selection with a color-coded system. This system helps users to easily identify products based on their specific requirements and applications.

| Color | Product | Features |

|---|---|---|

| Ultra Blue® | Medium Strength | Suitable for general-purpose gasketing and sealing. |

| Ultra Copper® | Maximum Temperature | Heat resistant, ideal for high-temperature applications. |

| Ultra Grey® | High Torque | High vibration and high-temperature resistance, perfect for heavy-duty tasks. |

This useful color coding ensures that users can quickly determine the appropriate product for their needs, enhancing usability and effectiveness.

Understanding these guidelines helps in making informed decisions when comparing different products, such as loctite blue vs. permatex blue, RTV silicone variants, and other adhesives for various applications. For further insights on specific comparisons, you may refer to articles like loctite 221 vs. 222 and loctite 242 vs. 262.

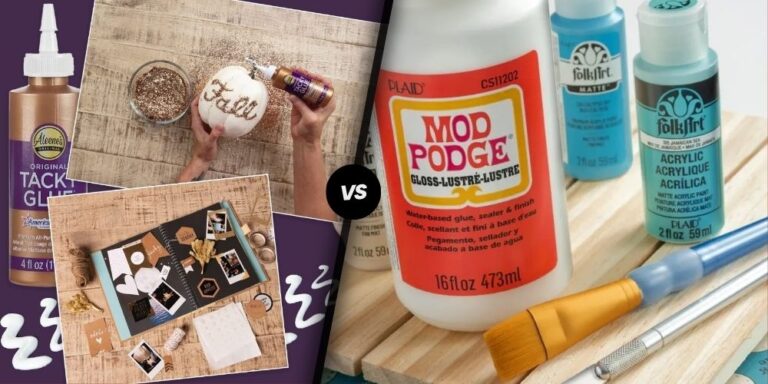

Choosing Between Loctite Blue and Permatex Options

When deciding between Loctite Blue and Permatex products, it’s essential to consider specific factors to ensure the best results for your project. Below, we will discuss the key considerations for selection and delve into different application scenarios.

Considerations for Selection

When choosing between Loctite Blue and Permatex options, several aspects must be taken into account:

- Type of Application:

- Loctite Blue Threadlocker (242): Designed for motorized and nonmotorized parts requiring occasional servicing. Suitable for car parts, bicycles, motorcycles, and more (Loctite Products).

- Permatex Ultra Copper RTV Silicone: Ideal for high-temperature applications requiring a copper-colored silicone that is not electrically conductive.

- Strength and Removability:

- Loctite Blue (242): Provides medium strength which is easily removable with hand tools. Ideal for applications needing regular disassembly.

- Permatex Ultra Copper: High-temperature resistance but low in mechanical bond strength. It’s more suitable for specific silicone applications rather than a general threadlocking use.

- Material Compatibility:

- Loctite Blue: Versatile and compatible with a variety of materials including metal, plastic, and wood.

- Permatex RTV Silicone: Best for sealing gaps, gasketing tasks, and not recommended for structural bonding.

- Color-Coding and Functionality:

- Permatex: Offers color-coded RTV Silicone variants indicating different strengths and specific uses (e.g., Ultra Blue for medium strength, Ultra Grey for high vibration) (Permatex FAQs).

| Product | Strength | Removability | Ideal For |

|---|---|---|---|

| Loctite Blue (242) | Medium | Easy with Hand Tools | Car Parts, Bikes, Equipment |

| Permatex Ultra Copper | High Temp | Not Primary Focus | High Temp, Non-Electrically Conductive Locations |

Application Scenarios

Different application scenarios demand specific product qualities. Here are hypothetical scenarios demonstrating when to use Loctite Blue vs. Permatex options:

- Automobile Maintenance:

- Scenario: Securing bolts on a car engine that need to be disassembled periodically.

- Best Choice: Loctite Blue (242). Its medium strength allows easy removal with hand tools, perfect for maintenance tasks (Loctite 248 vs. 242).

- High-Temperature Sealing:

- Scenario: Sealing an exhaust manifold joint exposed to high temperatures.

- Best Choice: Permatex Ultra Copper RTV Silicone. Ideally suited for high-temperature applications without electrical conductivity (Permatex FAQs).

- Gasketing Large Machinery:

- Scenario: Creating a gasket for machinery involving high torque and vibration.

- Best Choice: Permatex Ultra Grey RTV Silicone, owing to its high resistance to vibration and stability under high torque (Permatex FAQs).

- Household Appliances Assembly:

- Scenario: Assembling outdoor furniture where screws might need periodic tightening.

- Best Choice: Loctite Blue (242). Easy removability with common tools makes it suitable for household projects (Loctite Products).

Internal references to further understanding:

- Understand the comparison in deeper detail in our article Loctite 248 vs. 242.

- For different scenarios involving Loctite, read Loctite 242 vs. 262 and Loctite 243 vs. 263.

- Check leak lock vs. loctite for related applications in plumbing and sealing.

By evaluating the type of application, strength requirements, material compatibility, and specific functionalities such as high-temperature or mechanical strength, users can confidently choose between Loctite Blue and Permatex products for their particular needs.