Liquid Nails Vs. Silicone: Construction Bond Guide

Understanding Glue Strength

When comparing adhesives like Liquid Nails and wood glue, one of the primary factors to consider is their bond strength. Understanding the unique characteristics and capabilities of each can help users select the best option for their specific project.

Liquid Nails Bond Strength

Liquid Nails is a construction adhesive formulated for heavy-duty applications. It provides exceptionally strong bonding properties, making it suitable for projects that require durable and long-lasting adhesion. This adhesive is known for its versatility, able to bond various materials, including wood, metal, and concrete.

| Property | Liquid Nails |

|---|---|

| Bond Strength (psi) | Approximately 4,000+ |

| Breaking Point | Higher than wood glue |

| Ideal Uses | Heavy-duty construction |

Liquid Nails has a psi strength exceeding 4,000. The high breaking point ensures that joints adhered with Liquid Nails are less likely to break at the connection point compared to other adhesives (Quora).

For more detailed comparisons, you can visit our articles on jb weld vs. gorilla glue and e6000 vs. gorilla glue.

Wood Glue Bond Strength

Wood glue, particularly PVA-based wood glue, is commonly used for woodworking projects due to its strong bonding capabilities and ease of use. It boasts a bond strength that can withstand high levels of force without damage (Quora). Safe for use in poorly-ventilated spaces, wood glue emits no toxic fumes, making it ideal for indoor projects (US Vintage Wood).

| Property | Wood Glue |

|---|---|

| Bond Strength (psi) | 3,600 – 4,000 |

| Breaking Point | Lower than Liquid Nails |

| Ideal Uses | Woodworking, Indoor projects |

Wood glue has a psi strength between 3,600 and 4,000. It provides robust adhesion ideal for woodworking and other projects where non-toxic, easy-to-apply glue is preferred.

For additional insights into comparing adhesives, consider reading our articles on wood glue vs. white glue and rapid fuse vs. super glue.

By understanding these bond strengths and their practical applications, users can make informed decisions when choosing between Liquid Nails and wood glue for their projects. Ensure to take into account the specific requirements, such as bond strength, safety, and application surface, to achieve the best results.

Drying Time & Application Surfaces

Understanding the drying time and the types of surfaces each adhesive works best on is crucial when choosing between Liquid Nails and other types of adhesives like wood glue.

Drying Time of Wood Glue

Wood glue is known for its relatively fast drying time, which makes it a preferred choice for quick bonding projects. Generally, wood glue sets in about 30 minutes to an hour, depending on the type and brand. Some wood glues can dry completely within a couple of hours (US Vintage Wood).

| Glue Type | Initial Set Time | Full Drying Time |

|---|---|---|

| Wood Glue | 30 minutes – 1 hour | A few hours |

| Liquid Nails | At least 24 hours | Up to several weeks |

For more tips on effective gluing techniques, see our articles on wood glue vs. white glue.

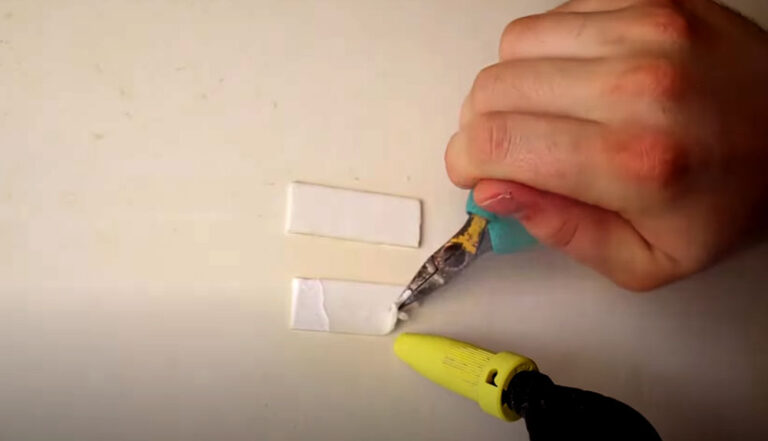

Application Surfaces for Liquid Nails

Liquid Nails is a versatile adhesive known for its strong bond and ability to adhere to a range of surfaces. This makes it an ideal choice for more complex construction projects:

- Wood

- Metal

- Glass

- Ceramic

- Concrete

- Drywall

- Brick

However, the key feature of Liquid Nails is its gap-filling capability, making it perfect for uneven or porous surfaces. Unlike wood glue, it forms a strong bond even when the surfaces are not perfectly aligned.

Their versatility comes with a trade-off in drying time. Liquid Nails typically requires a minimum of 24 hours to set, and complete curing can take several weeks depending on humidity levels and surface material (Signs101).

For additional information on different adhesives, explore our articles on dap rapid fuse vs. gorilla glue and 3m vhb vs. gorilla tape.

Gap-Filling Capabilities

When it comes to filling gaps in construction projects, wood glue and Liquid Nails have unique properties. Understanding these differences helps in choosing the best adhesive for your specific needs.

Sealing Gaps with Wood Glue

Wood glue is known for its ability to seal gaps effectively, especially when mixed with sawdust. This combination creates a strong bond and fills gaps in wood surfaces efficiently. Wood glue is particularly advantageous in woodworking projects where a smooth finish is desired.

| Property | Wood Glue |

|---|---|

| Composition | Polyvinyl acetate (PVA) |

| Gap-filling | Effective when mixed with sawdust |

| Durability | Highly durable, non-brittle |

Wood glue’s ability to fill gaps is enhanced by using sawdust from the same wood being adhered. This technique not only fills the gaps but also blends seamlessly with the wood, providing a consistent appearance. For more comparisons, explore our article on wood glue vs. white glue.

Gap-Filling with Liquid Nails

Liquid Nails, on the other hand, may not be as efficient in gap-filling. Though it is a strong construction adhesive, it tends to become brittle over time and may crack when used as a gap filler (USVintageWood).

| Property | Liquid Nails |

|---|---|

| Composition | Solvent-based or latex-based adhesiv |

| Gap-filling | Less effective; can become brittle |

| Durability | Durable but prone to cracking over time |

While Liquid Nails is effective for heavy-duty adhesive purposes, its brittleness when used as a gap filler makes it less ideal for filling gaps compared to wood glue. However, its strong bonding capability makes it suitable for securing larger construction elements. For comparing adhesive strengths and uses, read our guide on split by specific comparison link.

Understanding these differences is crucial for achieving the best results in your construction projects. For further insights on adhesives, check out 3m vhb vs. gorilla tape, and other related articles like gap vs. super glue.

Safety Considerations & Formulation

When choosing between Liquid Nails and wood glue, safety considerations and formulation are pivotal factors to take into account. Each adhesive has unique characteristics that can influence your decision based on the safety of use and the formulation of the product.

Safety of Wood Glue

Wood glue, particularly Polyvinyl Acetate (PVA) wood glues, is widely regarded as safer compared to some other adhesives. Most wood glues are water-based and do not emit harmful fumes, making them suitable for indoor use even in areas with limited ventilation (US Vintage Wood). This makes wood glue a popular choice for both DIY enthusiasts and professional carpenters.

| Adhesive Type | Safety Considerations |

|---|---|

| Wood Glue (PVA) | Safe for indoor use, non-toxic, minimal fumes |

| Liquid Nails | Requires ventilation, may emit harmful fumes |

Wood glue is generally non-toxic, easy to clean up with water, and does not pose significant health risks. For additional comparisons, you can explore our articles on wood glue vs. white glue and rubber cement vs. super glue.

Formulation of Liquid Nails

Liquid Nails is a construction adhesive that offers strong bonding capabilities. However, it is important to note that Liquid Nails may contain solvent-based ingredients that could emit toxic fumes when the adhesive is wet. Hence, it is crucial to use Liquid Nails in well-ventilated areas to mitigate potential health risks.

| Adhesive | Formulation Characteristics |

|---|---|

| Liquid Nails | Solvent-based, strong bond, emits fumes |

For those dealing with sensitive applications, the formulation of Liquid Nails should be considered carefully. The adhesive’s efficacy in a variety of surfaces is noteworthy, but safety precautions such as adequate ventilation and protective gear are vital during application. For detailed analyses, see our articles on e6000 vs. gorilla glue and does jb weld work on plastic.

Keep safety considerations and formulation aspects in mind when selecting an adhesive for your construction projects. Evaluate the specific requirements of your task and choose the product that aligns best with your needs. For more information on glue comparisons, refer to our in-depth articles on dap rapid fuse vs. loctite and how to remove e6000 glue.

Versatility & Specialty Formulas

When comparing adhesives for various projects, understanding the versatility and specialty formulas of Liquid Nails and wood glue is essential.

Liquid Nails Versatility

Liquid Nails is a highly versatile adhesive designed for a wide range of surfaces and applications. According to US Vintage Wood, this adhesive is suitable for heavy-duty construction materials such as concrete, paneling, and tileboard. Liquid Nails’ strong bonding properties make it an excellent choice for projects that require robust and durable adhesion.

| Material | Application |

|---|---|

| Concrete | Heavy-duty construction, concrete to concrete bonding |

| Paneling | Installing paneling and tileboard |

| Tileboard | Securing tiles and boards |

Liquid Nails is formulated specifically for construction purposes (USVintageWood), providing exceptional results for heavy-duty projects. When applied properly, it offers a bond strength that is difficult to break, ensuring long-lasting durability.

For more safety considerations and formulation details, you may want to check our sections on safety and formulation of Liquid Nails and explore other comparison articles, such as dap rapid fuse vs. gorilla glue.

Specialized Wood Glue Formulas

While Liquid Nails excels in construction applications, wood glue is typically used for woodworking and arts and crafts projects. Wood glue formulas are specialized to provide strong bonds specifically for wood-to-wood connections.

| Wood Glue Formula | Application |

|---|---|

| PVA (Polyvinyl Acetate) Glue | General woodworking, crafts |

| Hide Glue | Restoration and furniture repair |

| Epoxy-based Wood Glue | High-stress wood joints, outdoor woodworking |

Different types of wood glue, such as PVA glue, hide glue, and epoxy-based wood glue, cater to various needs within woodworking. For example, PVA glue is commonly used for general woodworking and craft projects, while hide glue is preferred for restoration and furniture repair. Epoxy-based wood glue is ideal for high-stress joints and outdoor applications.

For more detailed comparisons on various glues, explore our articles on wood glue vs. white glue and epoxy vs. super glue.

By understanding the versatility and specialized formulas of both Liquid Nails and wood glue, individuals can make informed choices for their specific project requirements. For further information on glue strength and drying times, check out our sections on strength and durability comparison and drying time and application surfaces.

Strength and Durability Comparison

Examining the strength and durability of adhesives is crucial for anyone tackling construction or woodworking projects. Below, we compare Liquid Nails and wood glue in terms of their bonding power and long-term performance.

Strength: Liquid Nails vs. Wood Glue

Liquid Nails offers formidable bonding properties, making it a preferred choice for many construction projects US Vintage Wood. It’s formulated to provide a robust bond across various materials beyond wood, including plywood, foam, leather, ceramic, metal, and glass.

On the other hand, wood glue, often used in woodworking projects, creates joints often stronger than the wood itself. It is best suited for bonding wood surfaces but can also adhere to materials like porcelain, metal, and plastic Quora.

| Adhesive | PSI Strength | Suitable Materials |

|---|---|---|

| Liquid Nails | Varies by formula (typically higher) | Wood, plywood, foam, leather, ceramic, metal, glass |

| Wood Glue | 3,600 – 4,000 | Wood, porcelain, metal, plastic |

Durability: Long-Term Comparison

In terms of durability, Liquid Nails provides long-lasting, heavy-duty bonds ideal for structural applications. This adhesive is designed to ensure that, if the bonded surfaces were pried apart, the breakage would occur at a different point rather than at the adhesive line Quora. This characteristic underlines its formidable lasting power and resistance to stress.

Wood glue also offers excellent durability but is primarily effective in woodworking scenarios where precisely milled wood surfaces are joined. The resulting bond from wood glue, when properly clamped, is typically as strong as or stronger than the wood itself, obviating the need for other fasteners (Quora).

Both adhesives have their strengths and ideal use cases. For construction projects requiring multi-material bonding and superior strength, Liquid Nails is often preferred. Meanwhile, for woodworking projects needing precision and strength, wood glue remains reliable.

For more comparisons and insights on adhesives, check out our other articles: rubber cement vs. super glue, epoxy vs. super glue, and dab rapid fuse vs. loctite.