E6000 vs E6000 Plus: Key Differences Explained

Understanding E6000 vs. E6000 Plus

E6000 and E6000 Plus are multipurpose adhesives from the same manufacturer, each catering to various bonding requirements. Let’s delve into what makes these adhesives unique and their respective benefits.

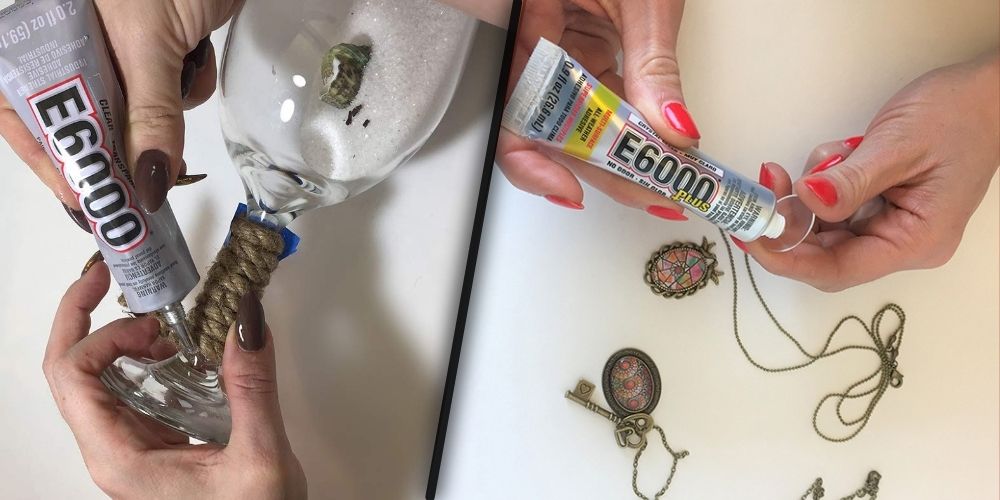

Introducing E6000 Adhesive

E6000 is an industrial-strength adhesive known for its strong adhesion and versatility. This clear-drying epoxy is flexible and exhibits exceptional bonding capabilities with numerous materials such as wood, metal, glass, ceramics, rubber, vinyl, leather, and most plastics. E6000 is particularly useful for challenging projects, including jewelry making and repairs, due to its robust and flexible bond.

However, users should note that E6000 has a strong odor due to solvents, making it less suited for indoor use without good ventilation. Despite this, its strong adhesion and flexibility are highly appreciated for a wide range of projects, from home repairs to crafting.

Benefits of E6000 Plus

E6000 Plus, a newer formulation, offers several advancements over the original E6000. Utilizing premium polymer technology, E6000 Plus is virtually odorless, making it safer and more suitable for indoor projects (Stickyn). Users benefit from its user-friendly nature, particularly for smaller or indoor projects where ventilation may be limited.

E6000 Plus maintains the versatility of the original, bonding effectively with materials such as wood, glass, metal, ceramic, and fabric. This adhesive is praised for its ease of use and its ability to deliver strong, flexible bonds without the unpleasant smell associated with solvent-based adhesives (Stickyn).

| Feature | E6000 | E6000 Plus |

|---|---|---|

| Odor | Strong | Virtually Odorless |

| Suitable for indoor projects | Less suitable without ventilation | Ideal |

| Versatility | High | High |

| Key materials bonded | Wood, glass, metal, ceramic, fabric, etc. | Wood, glass, metal, ceramic, fabric, etc. |

| User-friendliness | Moderate | High |

E6000 and E6000 Plus both offer robust solutions for a myriad of bonding needs. For more detailed comparisons, you can explore our articles on e6000 vs. jb weld and e6000 vs epoxy.

Performance and Application

When comparing E6000 vs. E6000 Plus, understanding their performance and applications is essential. These adhesives are designed for different needs, and knowing their strengths can help you choose the right one for your project.

Industrial Strength of E6000

E6000 is renowned for its industrial-strength bonding, making it suitable for heavy-duty applications. This adhesive provides exceptional adhesion to various materials, including wood, metal, glass, ceramics, rubber, vinyl, leather, and most plastics. It is particularly favored in projects requiring high-stress applications, such as armor crafting and outdoor repairs, due to its flexibility and durability.

Key Attributes:

- Industrial Strength: High adhesion for heavy-duty use

- Flexibility: Suitable for high-stress applications and outdoor projects

- Versatility: Bonds a wide range of materials

Versatility of E6000 Plus

E6000 Plus, while retaining some of the original E6000’s binding power, is designed with user-friendly attributes. It is more versatile for everyday, less intensive projects, offering ease of use and a lower odor (Stickyn). This makes E6000 Plus ideal for indoor applications and crafts that don’t require the same level of industrial strength but still need a strong adhesive.

Key Attributes:

- User-Friendly: Easier to use with reduced odor

- Versatile: Suitable for a variety of everyday projects

- Good Bonding: Maintains strong, flexible adhesion

Odor Comparison

A notable difference between E6000 and E6000 Plus is their odor. E6000 has a strong odor that often necessitates good ventilation, making it less suitable for enclosed spaces or for those sensitive to strong smells. On the other hand, E6000 Plus offers a lower odor formula, making it more pleasant to work with in indoor environments.

| Attribute | E6000 | E6000 Plus |

|---|---|---|

| Strength | Industrial strength for heavy-duty use | Versatile for everyday use |

| Flexibility | High stress and outdoor suitability | Good for flexible bonds |

| Odor | Strong, requires ventilation | Lower odor, indoor-friendly |

Choosing between these adhesives depends on the specific needs and preferences of your project. For high-stress, outdoor, or industrial applications, E6000 is preferred. For versatile, everyday use with comfort in mind, E6000 Plus is the better choice. Learn more about these adhesives, their applications, and user feedback in our sections on user feedback and recommendations and curing process and usage.

Curing Process and Usage

When comparing E6000 and E6000 Plus adhesives, understanding their curing process and usage is crucial. This will guide you in choosing the right adhesive for your specific project needs.

Curing Time of E6000

The curing time of E6000 can vary based on environmental conditions and the materials being bonded. Typically, E6000 cures within 24 to 72 hours (Stickyn). Initial bonding strength, which allows for light handling, can be achieved within 4 to 8 hours.

| Attribute | E6000 | E6000 Plus |

|---|---|---|

| Curing Time | 24 to 72 hours | 24 to 72 hours |

| Initial Bonding | 4 to 8 hours | 4 hours |

| Final Curing | Up to 72 hours | Up to 72 hours |

Initial Bonding Strength

E6000 is known for its exceptional initial bonding strength. It dries to a rubber-like consistency that is both flexible and durable, resisting cracking under stress (Stickyn). This makes E6000 suitable for projects that require some degree of movement and flexibility. E6000 Plus provides similar bonding strength with a slightly quicker initial bond time, making it a good alternative for faster projects.

Suitable Projects for Each

Understanding the suitable projects for each type of adhesive can help in making an informed decision.

-

E6000:

-

Ideal for heavy-duty projects requiring robust and resilient bonds.

-

Suitable for materials like metal, glass, plastic, and wood.

-

Great for outdoor and indoor use.

-

Perfect for demanding applications that require flexibility and durability.

-

E6000 Plus:

-

Excellent for projects needing a strong bond with quicker initial bonding time.

-

Suitable for similar materials as E6000, including fabric and leather.

-

Preferred for crafts, repairs, and quick fix jobs.

-

Suitable for those who are sensitive to strong odors, as it has a less pungent smell.

For more information on alternative adhesives and their applications, consider reading our articles on e6000 vs b7000 and e6000 vs jb weld.

By understanding the curing process, initial bonding strength, and suitable projects for each adhesive, you can make an informed choice between E6000 and E6000 Plus based on your project’s specific requirements.

User Feedback and Recommendations

User Satisfaction with E6000

E6000 is highly appreciated by users for its strong adhesion and flexibility. It performs exceptionally well in challenging projects, making it a top choice for high-stress applications. Users commend its industrial-strength bonding and clear-drying capabilities, which provide a reliable hold on various materials, including wood, metal, glass, ceramics, rubber, vinyl, leather, and most plastics (Stickyn).

E6000 has become a go-to adhesive for jewelry making and repairs due to its firm grip and transparent drying property. Jewelry crafters particularly value its effectiveness in securing jewelry findings, ensuring durability and longevity. Customer reviews on platforms like Amazon highlight its versatility and reliable performance, although opinions on its quality can vary.

Ideal Applications of E6000 Plus

E6000 Plus, on the other hand, is often praised for its user-friendly formula and lack of odor, making it suitable for indoor and smaller projects. This multipurpose adhesive, also by the same manufacturer, is known for its strong bonds and flexibility, though it caters more to less demanding applications compared to its counterpart.

Ideal applications for E6000 Plus include:

- Scrapbooking

- Household repairs

- Plastic, fabric, and paper crafts

- General DIY projects

The ease of use and odorless formulation make E6000 Plus an excellent choice for environments where ventilation may be limited. For users looking for a less intense adhesive with user-friendly features, this variant is often recommended.

Customer Reviews Comparison

| Feature | E6000 | E6000 Plus |

|---|---|---|

| Bonding Strength | Industrial strength | Versatile but milder |

| Odor | Strong | Odorless |

| User Satisfaction | High for challenging projects | High for indoor and smaller projects |

| Ideal Use | Jewelry making, high-stress applications | Crafts, household repairs |

| Flexibility | Excellent | Good |

Based on user feedback, the choice between E6000 and E6000 Plus often comes down to the nature of the project and the working environment. For heavy-duty applications requiring industrial-strength adhesion and flexibility, E6000 is the clear winner. For less demanding projects and scenarios where ease of use and odor are important, E6000 Plus is preferred. For a detailed overview of how these adhesives stack up against other types, visit our article on e6000 vs e7000 glue.

Both variants offer strong bonds and versatility, making them valuable additions to any DIY enthusiast’s toolkit. For further comparisons, you can explore their features against other adhesives like b7000 vs. super glue, e6000 vs b7000, and e6000 vs epoxy.

Safety and Health Considerations

When comparing E6000 vs. E6000 Plus, it’s essential to consider the safety and health implications of each adhesive. Both products have distinct characteristics that affect their suitability for various projects.

Health Risks with E6000

E6000 adhesive is renowned for its industrial strength and versatility. However, it comes with certain health risks. One of the primary concerns is its composition, which includes chemicals such as toluene and xylene. These solvents can cause skin irritation and other adverse effects, particularly when used in enclosed spaces (Quora).

| Health Risk | Description |

|---|---|

| Skin Irritation | Can cause redness and itching upon contact. |

| Respiratory Issues | Inhalation of fumes can lead to dizziness and nausea. |

| Chemical Exposure | Contains toluene and xylene, which may cause long-term health effects. |

Given these potential hazards, it’s crucial to use E6000 with proper ventilation and protective gear, such as gloves and masks.

Odor Sensitivity

One of the most notable differences between E6000 and E6000 Plus is their odor. E6000 has a strong and pungent smell due to its solvent-based composition. This makes it less suitable for indoor use, especially in spaces with poor ventilation (Stickyn).

On the other hand, E6000 Plus is virtually odorless due to its premium polymer technology (Stickyn). This feature makes it an excellent option for those who are sensitive to strong odors or prefer to work on indoor projects without the inconvenience of a lingering smell.

| Adhesive Type | Odor Level |

|---|---|

| E6000 | Strong |

| E6000 Plus | Virtually Odorless |

Safety Features of E6000 Plus

E6000 Plus not only boasts a virtually odorless formula but also incorporates enhanced safety features. It does not contain the same level of harmful solvents as E6000, making it a safer choice for a broader range of users and applications.

Key safety features of E6000 Plus include:

- Virtually odorless, reducing the risk of respiratory irritation.

- Lower levels of harmful solvents, making it safer for prolonged use.

- Suitable for indoor projects and enclosed spaces.

These features make E6000 Plus particularly appealing for users concerned about health and safety, especially when working on crafts, DIY projects, or repairs inside homes.

For those interested in learning more about how these adhesives compare in terms of application and performance, refer to our article on E6000 vs JB Weld to see how they stack up against other strong adhesives.

Pricing and Availability

When choosing between E6000 and E6000 Plus, understanding their pricing, packaging options, and availability is essential.

Cost Comparison

The cost can vary depending on the packaging and vendor. Below is a comparison of the costs for E6000 and E6000 Plus.

| Product | Pack Size | Price (USD) | Price per Fl Oz (USD) |

|---|---|---|---|

| E6000 Plus | 0.9 oz | $9.30 | $10.33 |

| E6000 Plus | 2-pack (0.9 oz each) | $25.12 | $13.96 |

| E6000 | 1 oz | $4.78 | $4.78 |

| E6000 | 2 oz | $7.50 | $3.75 |

Source: Amazon

Packaging Options

E6000 and E6000 Plus are available in various packaging options to accommodate different usage needs. Here are some common packaging sizes:

| Product | Available Sizes |

|---|---|

| E6000 Plus | 0.9 oz, 2-pack (0.9 oz each) |

| E6000 | 1 oz tube, 2 oz tube, 3.7 oz tube |

The E6000 adhesive is widely known for its industrial-strength bonding capabilities, making it a versatile option for numerous applications. On the other hand, E6000 Plus offers similar strength but is available in more user-friendly packaging, such as smaller tubes, which can be more convenient for personal projects.

Availability on the Market

Both adhesives are readily available through various online and physical retailers, including major e-commerce platforms like Amazon, hardware stores, and craft supply shops. The availability might differ based on regional distribution, but you can commonly find these products in:

- Online marketplaces (e.g., Amazon)

- Home improvement stores (e.g., Home Depot, Lowe’s)

- Craft and hobby stores (e.g., Michaels, Hobby Lobby)

For more information on other adhesives, check out our comparisons of E6000 vs. JB Weld and E6000 vs Super Glue. Additionally, explore E6000 vs Epoxy if you’re interested in understanding the strengths of different adhesive types.

Ultimately, both E6000 and E6000 Plus provide robust bonding solutions, but their cost, packaging, and availability might influence your choice depending on your specific needs and project requirements.