What is the Strongest Glue: Ultimate Guide

Understanding Strong Adhesives

To effectively choose the strongest glue, it’s important to grasp the basics of strong adhesives and their significance in various applications.

Testing Adhesive Strength

Adhesive strength is typically assessed by hanging progressively heavier weights on a glued test strip until the joint fails. Professionals employ specialized apparatus to clamp the test strips and accurately measure the force required to tear the glue joint apart. This meticulous testing ensures that the adhesive performs reliably under specific conditions.

| Testing Parameter | Description |

|---|---|

| Weight Capacity | Measures how much weight the glue can hold before failing |

| Clamp Force | Determines the pressure needed to detach the glued surfaces |

| Environmental Factors | Assesses the glue’s performance under various temperatures and humidity levels |

Learn more about specific adhesives and their strengths in our what is the strongest jb weld article.

Importance of Adhesive Strength

The strength of an adhesive is crucial in ensuring the durability and reliability of bonded assemblies. Two key components determine an adhesive’s performance: adhesive strength and cohesive strength.

Adhesive Strength: This is the interfacial strength between the adhesive and the substrate. It is the most vital consideration when designing a robust bonded assembly. Even the toughest glue can fail if it does not bond well to the substrate’s surface.

Cohesive Strength: This refers to the internal strength of the adhesive, dictated by its chemical composition. Higher cohesive strength means a stronger adhesive, which ranges from pressure-sensitive adhesives to structural epoxy and acrylic types.

| Type of Strength | Description |

|---|---|

| Adhesive Strength | Bond strength between adhesive and surface |

| Cohesive Strength | Internal bond strength within the adhesive |

Importance of Surface Energy and Cleanliness

The surface energy of a substrate is crucial for adhesive selection. High surface energy promotes intimate contact between adhesive and substrate, enabling the adhesive to wet out the surface effectively and form a robust bond. Cleanliness is equally important as any dirt or oil present can hinder the bonding process.

Understanding these factors is essential when choosing the right adhesive for your needs. For more on ensuring proper adhesion, see our guide on surface preparation for adhesives.

Taking all these factors into account helps in selecting an adhesive that offers the strongest and most reliable bond for your specific application.

Applications of Adhesives

Adhesives play a critical role in various industries, providing strength, flexibility, and durability. This section explores the use of adhesives in transportation, woodworking, and wind power.

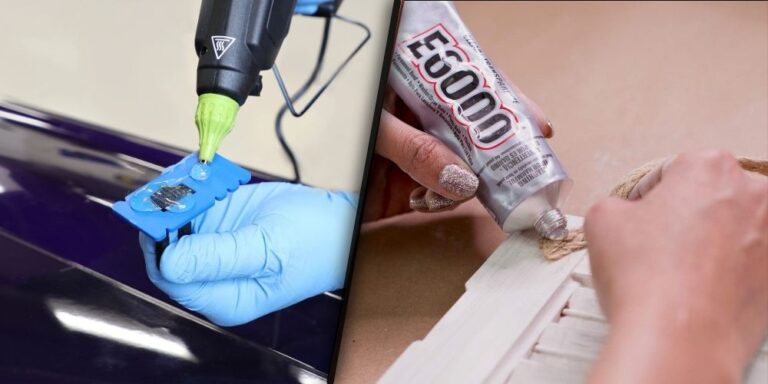

Adhesives in Transportation

The transportation industry depends heavily on adhesives for the manufacturing and assembly of vehicles. Adhesives are utilized for components in cars, airplanes, and trains, aiding in parts manufacturing and vehicle assembly. These adhesives are favored for their impact-absorbing properties, which enhance both the safety and aesthetic appeal of vehicles.

| Vehicle Type | Common Adhesive Applications |

|---|---|

| Cars | Body panels, interior trims, glass bonding |

| Airplanes | Composite materials, structural bonding |

| Trains | Flooring, panels, insulation |

The use of high-quality adhesives in transportation ensures that vehicles can withstand the rigors of daily use while maintaining structural integrity and safety standards.

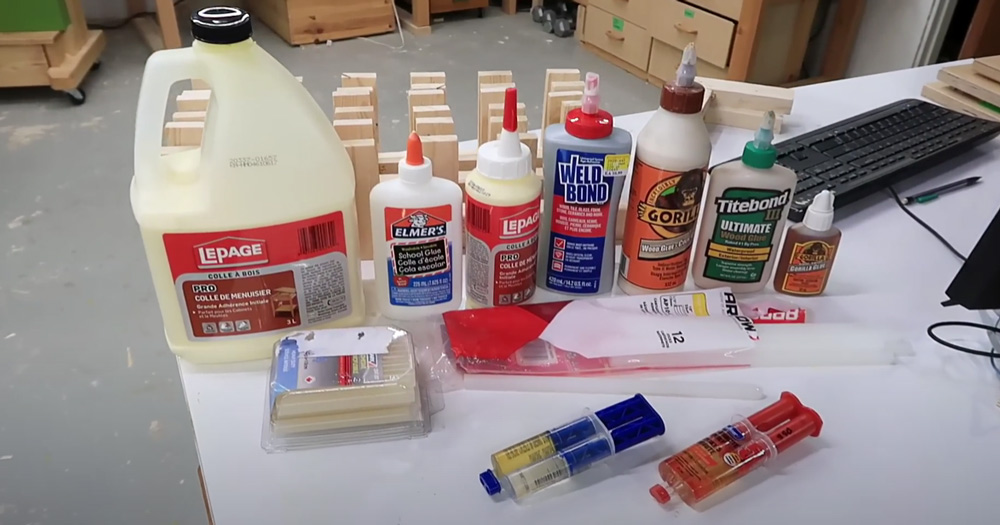

Adhesives in Woodworking

In the woodworking industry, adhesives are integral to creating a variety of products, from kitchen and bathroom cabinets to residential and commercial furniture. Adhesives like Adbond 3409 provide the necessary strength for items such as sandwich panels and furniture made from laminate or wood veneer.

Common woodworking adhesives include:

- Wood glues: Ideal for strong bonds in furniture assembly.

- Epoxy resins: Suitable for filling gaps and providing a robust finish.

- Polyurethane adhesives: Excellent for outdoor furniture due to their water resistance.

Using the right adhesive ensures not only the longevity but also the quality and finish of the wooden products.

| Adhesive Type | Common Applications |

|---|---|

| Wood Glues | Cabinet making, furniture joints |

| Epoxy Resins | Structural repairs, gap filling |

| Polyurethane Adhesives | Outdoor furniture, decking |

For an in-depth comparison of adhesives used in woodworking, visit titebond 3 vs gorilla wood glue.

Adhesives in Wind Power

Adhesives in the wind power sector are crucial for bonding structural parts, streamlining assembly processes. The adhesives used in this industry cure quickly at room temperature, which is essential for efficient production. This efficiency is vital as the renewable energy sector continues to expand rapidly.

Adhesives in wind power contribute to:

- Structural bonding: Ensuring the integrity of large components.

- Assembly optimization: Reducing the time and complexity of manufacturing.

| Application | Benefits |

|---|---|

| Structural Bonding | Enhanced durability and integrity of components |

| Assembly Optimization | Faster production cycles and reduced complexity |

Understanding the diverse applications of adhesives not only emphasizes their importance but also highlights their role in advancing technology and improving product quality.

Types of Strong Adhesives

Understanding the different types of strong adhesives is essential for anyone looking to determine what is the strongest glue. Here, we will discuss three popular types of strong adhesives: epoxy adhesives, polyimide adhesives, and hot melt adhesives.

Epoxy Adhesives

Epoxy adhesives are well-known for their exceptional bonding capabilities and versatile applications. These adhesives are highly resistant to temperature and solvents, making them suitable for a wide range of materials, including metals, ceramics, wood, and plastics.

| Property | Value |

|---|---|

| Temperature Resistance | Up to 200°C |

| Solvent Resistance | High |

| Material Compatibility | Metals, Ceramics, Wood, Plastics |

Epoxy adhesives are often used in industrial settings for their structural bonding strength. They are ideal for applications that require a durable and long-lasting bond. For more on the industrial use of epoxy adhesives, visit our article on industrial and specialized adhesives.

Polyimide Adhesives

Polyimide adhesives are celebrated for their immense strength and resistance to heat and chemicals. These adhesives can perform in extremely high temperatures, up to 500 degrees Celsius, making them suitable for specialized high-temperature applications.

| Property | Value |

|---|---|

| Temperature Resistance | Up to 500°C |

| Chemical Resistance | High |

| Material Compatibility | Various |

The robust nature of polyimide adhesives makes them ideal for applications in fields such as aerospace and electronics, where materials are subjected to extreme conditions.

Hot Melt Adhesives

Hot melt adhesives are popular for their ease of use and environmental friendliness. These adhesives can be categorized into EVA-based, APAO-based, and pressure-sensitive types. They are valued for their safety, eco-friendliness, and shelf life.

| Property | EVA-based | APAO-based | Pressure-sensitive |

|---|---|---|---|

| Eco-friendliness | High | Medium | High |

| Safety | High | High | High |

| Shelf Life | Long | Medium | Long |

Hot melt adhesives are commonly used in packaging, woodworking, and various consumer goods due to their quick bonding and ease of application. For those interested in exploring these adhesives, see our specific guides on most common types of adhesives.

For more tips on how to use various types of adhesives, check out related articles such as how to use shoe goo and what will dissolve jb weld.

Best Glues for Specific Materials

Choosing the right adhesive for various materials is crucial for achieving strong and durable bonds. Here, we explore some of the best adhesives available for different applications, ensuring you use the most effective product for your needs.

Gorilla Super Glue Gel

Gorilla Super Glue Gel is known for its versatility and is considered the best overall pick for the strongest glue. This adhesive has a no-run formula ideal for vertical surfaces and offers a quick-drying time of 10 to 45 seconds. It can bond well with various materials, including wood, metal, ceramic, stone, leather, fabric, rubber, paper, and most plastics. It also offers resistance to shock, impact, and weather conditions, making it a reliable choice for various applications.

| Property | Value |

|---|---|

| Drying Time | 10-45 seconds |

| Bonding Materials | Wood, Metal, Ceramic, Stone, Leather, Fabric, Rubber, Paper, Most Plastics |

| Resistance | Shock, Impact, Weather |

Loctite Ultra Gel Control

Loctite Ultra Gel Control is an affordable yet effective option for strong adhesive needs. Its rubberized formula provides a powerful and long-lasting bond, resistant to wear, shock, impact, and vibration. It bonds to a range of household materials such as plastic, wood, metal, fabric, and ceramic. Loctite Ultra Gel Control sets in one minute and cures completely within 24 hours, making it both fast and reliable.

| Property | Value |

|---|---|

| Drying Time | 1 minute |

| Complete Cure Time | 24 hours |

| Bonding Materials | Plastic, Wood, Metal, Fabric, Ceramic |

| Resistance | Wear, Shock, Impact, Vibration |

The Original Super Glue Super Glue

The Original Super Glue Super Glue is particularly effective for ceramic applications. It offers a powerful bond on materials like porcelain and ceramic, with a 30-second drying time. The precision applicator tip makes it suitable for detailed projects and small items like china, jewelry, memorabilia, and collector’s items.

| Property | Value |

|---|---|

| Drying Time | 30 seconds |

| Bonding Materials | Porcelain, Ceramic |

| Applicator | Precision Tip |

J-B Weld Original Cold-Weld Formula

For metal applications, J-B Weld Original Cold-Weld Formula is often the best choice. This steel-reinforced epoxy creates an exceedingly strong waterproof bond, suitable for metals like pipes, car parts, drains, screens, fixtures, or appliances. It sets in 4-6 hours and can be drilled or sanded as needed.

| Property | Value |

|---|---|

| Setting Time | 4-6 hours |

| Bonding Materials | Metal (Pipes, Car Parts, Drains, Screens, Fixtures, Appliances) |

| Additional Features | Can be Drilled or Sanded |

For more details on J-B Weld products, you can visit our J-B Weld category.

Aleene’s Original Super Fabric Adhesive

Aleene’s Original Super Fabric Adhesive is recommended for fabric projects. This adhesive offers a quick-drying, clear, and flexible bond suitable for materials like cotton, denim, nylon, linen, and elastic. It allows for machine-washable usage and is ideal for attaching embellishments such as beads, sequins, and lace.

| Property | Value |

|---|---|

| Drying Time | Quick-drying |

| Bonding Materials | Cotton, Denim, Nylon, Linen, Elastic |

| Usage | Machine-Washable |

For further tips on working with specific materials, check out our guides on mod podge sparkle vs. extreme glitter.

Industrial and Specialized Adhesives

Adhesives play a significant role in various industrial and specialized sectors. Their versatility and strength make them indispensable in many applications, from medical tools to transportation systems.

Adhesives in the Medical Sector

In the medical field, adhesives offer strong bonding and sealing capabilities essential for assembling surgical tools and disposable devices. These adhesives ensure that instruments coming into contact with blood or other body fluids are reliably sealed. This eliminates the need for screws or bolts, making medical devices safer and more efficient (Permabond).

Adhesives in the Defense Industry

In the defense industry, adhesives are crucial for bonding, coating, and sealing various materials. Military systems utilize adhesives for items such as guns, goggles, radios, gas masks, helmets, and bullets. The structural adhesive chemistry ensures that all components are securely joined, enhancing both performance and safety.

Adhesives in Ground Transportation

Adhesives are widely used in ground transportation industries, including rail and automotive sectors. They bond electric motors, provide gasketing for internal combustion engines, seal hydraulic lines, and coat electrical connections. Additionally, adhesives are employed to attach accessories and trims, showing their versatility in these applications. For insights on specific adhesive products for automotive use, visit our comparison of nylon patch vs. loctite.

Adhesives in Prefabricated Houses

Prefabricated houses rely on adhesives for assembling various components, including sub-flooring, bathrooms, moldings, and kitchen equipment. Manufacturers prioritize long-lasting and durable adhesives to ensure the stability and longevity of these structures. Proper adhesive application guarantees that prefabricated houses remain robust and reliable over time. Additional tips on using adhesives in home improvement can be found in our guide on subfloor adhesive.

Adhesives for Security Tape Manufacturers

Security tape manufacturers depend on strong adhesives, particularly hot melt adhesives, for specialized packaging requirements. These adhesives provide robust adhesion, leaving evidence of tampering to ensure the security of packaged items. For more information on how adhesives are used in packaging, read our article on adhesive vinyl.

To sum up, the strength and versatility of adhesives contribute significantly to various industries, ensuring safety, reliability, and efficiency in their respective applications. Understanding the specific requirements of each industry allows for the selection of the most appropriate adhesive solutions.

Factors for Strong Adhesive Bonds

Understanding the factors that contribute to strong adhesive bonds is crucial in determining what is the strongest glue for your specific needs. These factors include the bond between the adhesive and the substrate, cohesive strength, types of stress, and surface energy and cleanliness.

Adhesive vs. Substrate Bond

Adhesive strength refers to the interfacial strength between the adhesive and the substrate. Even with the world’s toughest adhesive, a bond can fail if the adhesive does not effectively bond to the surface of the substrate. This emphasizes the importance of selecting an adhesive compatible with the substrate’s material.

| Factor | Significance |

|---|---|

| Adhesive Strength | Determines the bond between adhesive and substrate |

| Substrate Compatibility | Ensures optimal bonding |

Cohesive Strength of Adhesives

Cohesive strength is the internal strength of the adhesive, determined by its chemical composition. The higher the cohesive strength, the more robust the adhesive. Cohesive strength varies widely, from pressure-sensitive adhesives to structural epoxy and acrylic adhesives.

| Type of Adhesive | Cohesive Strength |

|---|---|

| Pressure-Sensitive Adhesives | Low |

| Structural Epoxy | High |

| Acrylic Adhesives | High |

Understanding Different Stress Types

Different types of stress can act on an adhesive joint, affecting its performance. These stresses include shear, cleavage, peel, and tensile stresses. Understanding these stress types can help in selecting an adhesive with the best cohesive strength for the application.

| Stress Type | Description |

|---|---|

| Shear Stress | Parallel to the joint surface |

| Cleavage Stress | Acts along the bond line |

| Peel Stress | Concentrated at the leading edge |

| Tensile Stress | Perpendicular to the joint surface |

Importance of Surface Energy and Cleanliness

Surface energy of a substrate is crucial in adhesive selection, with high surface energy promoting intimate contact between the adhesive and substrate. Adhesives must ‘wet out’ the substrate effectively to form a strong bond. Cleanliness of the surface also plays a significant role in achieving optimal adhesion.

| Factor | Importance |

|---|---|

| Surface Energy | Promotes intimate contact |

| Cleanliness | Ensures effective bonding |

For additional insights on adhesives and their applications, check our articles on liquid nails vs. sikaflex, and is jb weld conductive. Understanding these factors will help you make an informed decision about the strongest adhesive for your needs.