What Adhesive Sticks to Brick: Pro Guide

Adhesives for Brick Surfaces

Understanding the options for adhesives that stick to brick is essential for achieving a strong bond. In this section, we will cover surface preparation for brick adhesives and the types of adhesives suitable for brick surfaces.

Surface Preparation for Brick Adhesives

Surface preparation is crucial to ensure the adhesive bonds effectively to the brick. This involves three key steps: removing contaminants, roughening the surface, and sometimes modifying the chemical composition.

-

Cleaning the Surface:

- Use liquid solvents or isopropyl alcohol to remove dust, dirt, oil, and grease.

- Ensure the brick is dry and free from any residues.

-

Surface Abrasion:

- Sanding the brick surface can help create a rough texture, improving adhesive grip.

- Techniques such as laser texturing or acid etching can be effective.

-

Chemical Treatments:

- Treatments like plasma or certain chemical agents can enhance adhesion by altering the brick’s surface structure (Gluegun.com).

| Preparation Step | Methods |

|---|---|

| Cleaning | Liquid solvents, isopropyl alcohol |

| Abrasion | Sanding, laser texturing, acid etching |

| Chemical Treatment | Plasma treatment |

For more detailed techniques, visit our guide on how to glue bricks together.

Types of Adhesives for Brick

When it comes to selecting the right adhesive for brick, there are several options to consider based on the application and weight of the objects being attached.

-

Brick Clips:

- Ideal for lighter objects.

- No drilling required; clips grip onto bricks securely.

-

Adhesive Hooks:

- Suitable for items that are medium in weight.

- Easy to apply and remove without causing damage.

-

Construction Adhesive:

- Provides a permanent and robust hold.

- Best suited for heavier items.

Read more about how to glue arrow inserts for similar techniques.

| Adhesive Type | Best For | Pros |

|---|---|---|

| Brick Clips | Light Objects | No drilling, Reusable |

| Adhesive Hooks | Medium Weight | Easy application, No damage |

| Construction Adhesive | Heavy Objects | Permanent hold, Strong |

For more suggestions on adhesives and their applications, see our articles on can you use super glue for arrow inserts and what adhesive sticks to ceramic tile.

Choosing the right adhesive and preparing the brick surface properly will significantly enhance adhesion, ensuring stability and longevity of the bond. Explore different products and methods to find what works best for your specific needs.

Techniques for Bonding to Brick

Understanding the techniques for bonding to brick surfaces can significantly enhance the efficiency of your project. Below, we delve into the practical applications of brick clips, adhesive hooks, and construction adhesive.

Brick Clips and Adhesive Hooks

Brick clips and adhesive hooks serve as convenient solutions for attaching items to brick walls without the need for drilling. Brick clips are designed to grip onto the brick securely without causing damage, suitable for hanging lightweight to medium-weight items. Adhesive hooks, on the other hand, are ideal for lighter objects and offer an easy application process.

| Technique | Ideal Use | Weight Capacity |

|---|---|---|

| Brick Clips | Hanging decorations, frames | Up to 25 lbs |

| Adhesive Hooks | Lightweight items, small tools | Up to 5 lbs |

Before using either method, it is crucial to clean the brick surface thoroughly to ensure optimal adhesion (Quora). For a more permanent solution, construction adhesive is recommended.

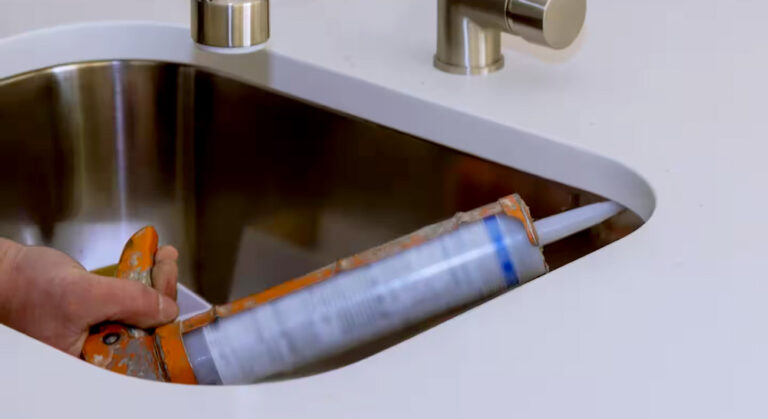

Construction Adhesive Applications

Construction adhesive provides a strong, permanent bond suitable for heavier objects. Several specialized products are designed to cater to different requirements:

-

Loctite PL 500 Landscape Block Adhesive: Formulated for outdoor use, weatherproof, and can bond wet or dry surfaces. Ideal for applications involving weather exposure (Loctite Products).

-

Loctite PL 375 Heavy Duty Construction Adhesive: Suitable for heavy-duty bonding of all common building materials, usable both indoors and outdoors. This adhesive provides strong, reliable bonds, making it versatile for various applications (Loctite Products).

| Adhesive | Ideal Use | Features |

|---|---|---|

| Loctite PL 500 | Landscaping projects | Weatherproof, bonds wet or dry |

| Loctite PL 375 | General construction | Heavy-duty, flexible applications |

When using construction adhesive, follow the manufacturer’s instructions regarding surface preparation, application, curing time, and cleanup procedures to ensure a successful bond. For those looking for a quick and efficient bonding solution, stronger adhesive formulas like Loctite PL Premium Fast Grab can save time, reducing the need for additional bracing.

For more information on choosing the right adhesive for various uses, visit our articles on what adhesive sticks to ceramic tile and what adhesive sticks to silicone.

Weatherproof Adhesives for Brick

When it comes to bonding materials to brick surfaces, the choice of adhesive is crucial. Here, we’ll explore two weatherproof adhesives: Adiseal Weatherproof Adhesive and Adiseal Ultra Clear Adhesive.

Adiseal Weatherproof Adhesive

Adiseal Weatherproof Adhesive is a robust option for both internal and external applications. It offers a 100% water-resistant bond, making it ideal for projects exposed to moisture. This includes dry, damp, wet, and even underwater conditions (Adiseal).

In independent tests, Adiseal was found to be the strongest construction adhesive, surpassing its competitors by over three times. It achieved an impressive adhesive bond strength of 3123 psi when tested between hardwood and metal surfaces (Adiseal).

Additionally, Adiseal exhibited exceptional resistance to mold. During a test where various adhesives were submerged in water for 90 days, Adiseal remained mold-free.

Key Features:

- Versatile Material Bonding: Suitable for metal, wood, plastic, glass, and more.

- Extreme Strength: Adhesive bond strength of over 3123 psi.

- Mold Resistance: No mold growth after 90 days underwater.

For more information about adhesives, check out our article on what adhesive sticks to ceramic tile.

Adiseal Ultra Clear Adhesive

Adiseal Ultra Clear Weatherproof Adhesive is renowned for its transparency, retaining its clarity even when exposed to water. Unlike some clear adhesives that may become cloudy upon application, Adiseal Ultra Clear maintains its transparency, making it suitable for applications where visibility is crucial (Adiseal).

This adhesive is perfect for projects that demand an aesthetically pleasing finish without compromising strength and durability. It’s suitable for use in a variety of construction and repair projects, offering the same level of water resistance as the standard Adiseal Weatherproof Adhesive.

Key Features:

- Transparency: Maintains clarity even when exposed to water.

- Multi-material Bonding: Effective on metal, wood, plastic, glass, and more.

- Waterproof Performance: Ideal for visible areas exposed to moisture.

For tips on selecting the right adhesive for your project, consider visiting choosing the right adhesive.

Performance Comparison Table

| Feature | Adiseal Weatherproof Adhesive | Adiseal Ultra Clear Adhesive |

|---|---|---|

| Water Resistance | 100% waterproof | 100% waterproof |

| Bond Strength (psi) | 3123 | High (Similar to standard) |

| Mold Resistance | Excellent | Excellent |

| Transparency | Clear | Ultra clear |

| Suitable Materials | Metal, wood, plastic, glass | Metal, wood, plastic, glass |

| Application Conditions | Dry, damp, wet, underwater | Dry, damp, wet, underwater |

Using the right adhesive is critical for successful bonding projects. For more information on adhesives and their uses, explore our articles on what can i use instead of spray adhesive and what adhesive sticks to glass.

Factors Affecting Adhesive Strength

High-Temperature Resistance

High-temperature resistance is crucial when selecting an adhesive for brick surfaces, especially for outdoor or non-temperature-controlled areas. Exposure to high temperatures can cause some adhesives to soften, compromising their ability to bond effectively. Therefore, it’s essential to choose adhesives that maintain their integrity under heat. For instance, LORD 305 epoxy adhesive is recommended for maintaining temperature resistance (Chemical Concepts).

LORD 7610DTM Direct-to-Metal Adhesive is another suitable option for high-heat environments as it maintains elasticity, preventing the adhesive from becoming brittle and ensuring sustained bonding strength (Chemical Concepts). Selecting temperature-resistant adhesives is crucial to safeguarding the bond throughout temperature fluctuations, avoiding degradation of the adhesive’s efficacy.

| Adhesive Type | Temperature Resistance | Suitable For |

|---|---|---|

| LORD 305 Epoxy Adhesive | High | Outdoor, High-Temperature Areas |

| LORD 7610DTM Direct-to-Metal | Moderate to High | High-Heat Conditions |

Environmental Impact on Adhesives

Environmental conditions significantly influence the performance and strength of adhesives used on brick surfaces. Factors such as temperature, humidity, exposure to chemicals, and UV light can affect bonding strength and durability.

Adhesives exposed to fluctuating temperatures may lose their flexibility or become brittle, leading to bond failure. Similarly, high humidity levels can affect the curing process, impacting the adhesive’s final strength. UV exposure can deteriorate the adhesive over time, leading to weakened bonds.

By selecting adhesives formulated to withstand these environmental conditions, such as weatherproof or UV-resistant options, you can ensure a more durable and reliable bond. Additionally, considering curing time and method is paramount. Properly allowing adhesives to dry and using the appropriate curing techniques are critical for achieving optimal bonding strength (Source).

For more detailed comparisons of adhesive types, refer to our resources on dap vs. ge silicone and ge advanced vs. supreme silicone.

| Environmental Factor | Impact on Adhesives | Solution |

|---|---|---|

| Temperature Fluctuations | Softening/Brittleness of Adhesive | Use Temperature-Resistant Adhesives |

| Humidity | Affects Curing Process | Ensure Proper Curing Conditions |

| UV Exposure | Deteriorates Adhesive Strength | Use UV-Resistant Adhesives |

| Chemical Exposure | Weakens Bond Strength | Choose Chemically Resistant Adhesives |

Understanding these factors can guide the selection of the best adhesive for brick, ensuring effective and long-lasting results. For additional guidance on adhesive selection and usage, refer to our articles on how to glue bricks together and what adhesive sticks to glass.

Top Brick Adhesive Products

Loctite PL 500 Landscape Block Adhesive

When looking for a reliable adhesive for bonding bricks, the Loctite PL 500 Landscape Block Adhesive stands out as a top choice. This adhesive is explicitly formulated for landscape block projects and other similar applications source.

Key features of Loctite PL 500 include:

- Weatherproof: Suitable for both wet and dry conditions, making it ideal for outdoor projects.

- Application Temperature: Can be used in various weather conditions.

- Versatility: Great for bonding concrete, brick, and stone.

Specifications

| Feature | Details |

|---|---|

| Bond Strength | High |

| Weather Resistance | Yes |

| Application Temperature | All Weather |

| Usage | Outdoors, Landscape |

Further details on how to use 3m panel bonding adhesive can improve your understanding of adhering different materials.

Loctite PL 375 Heavy Duty Adhesive

Loctite PL 375 Heavy Duty Construction Adhesive offers robust bonding suitable for various building materials. It is perfect for both indoor and outdoor use but not recommended for landscaping walls source.

Key features of Loctite PL 375 include:

- High Bond Strength: Ensures a durable and strong hold on most common building materials.

- Versatility: Effective for wood, metal, concrete, brick, and masonry.

- Indoor and Outdoor Use: Suitable for various environmental conditions.

Specifications

| Feature | Details |

|---|---|

| Bond Strength | Extremely High |

| Weather Resistance | Yes |

| Application Temperature | Indoor/Outdoor |

| Usage | General Construction |

Learning about how strong is JB Weld and other adhesives may offer additional perspective on different bonding solutions.

For more insights into adhesive applications for different surfaces, consider exploring our articles on what adhesive sticks to ceramic tile and how to glue bricks together.

Tips for Successful Brick Bonding

To achieve a durable and reliable bond when working with brick surfaces, it is essential to follow a set of best practices. The two primary considerations are proper surface preparation and choosing the right adhesive.

Proper Surface Preparation

Surface preparation is crucial when bonding adhesive to brick. Ensuring that all surfaces are clean and structurally sound is necessary for a successful bond. Here are the main steps for preparing a brick surface:

- Removing Contaminants: Use isopropyl alcohol or a similar solvent to clean the brick surface. This step removes dust, dirt, oil, and other contaminants that can hinder the adhesive’s effectiveness.

- Abrasion: Lightly sanding the brick surface helps to create a rougher texture, increasing the surface area for the adhesive to bond.

- Chemical Treatments: While often used for metal surfaces, certain chemical treatments can also be beneficial for brick. For example, acid etching can help to modify the surface for better adhesive bonding (Gluegun.com).

Proper preparation ensures that the adhesive will form a strong, lasting bond with the brick. Detailed guidance can be found in our article on how to glue bricks together.

Choosing the Right Adhesive

Choosing the appropriate adhesive for brick surfaces is just as critical as proper surface preparation. Environmental conditions, material compatibility, and intended application influence the effectiveness of the adhesive (Source). Here are some key factors to consider:

- Temperature and Environmental Conditions: Select an adhesive that is compatible with the temperature and humidity of your environment. For example, weatherproof adhesives like Adiseal Weatherproof Adhesive offer excellent performance under extreme weather conditions.

- Material Compatibility: Ensure the adhesive is suitable for bonding brick. Some adhesives, like Loctite PL 500 Landscape Block Adhesive and Loctite PL 375 Heavy Duty Adhesive, are specifically formulated for brick and masonry applications.

- Curing Time and Method: Different adhesives require varying curing times and methods. Follow the manufacturer’s instructions to achieve maximum bonding strength. Proper curing is crucial, especially under adverse environmental conditions (Source).

To understand the best products available, visit our reviews on top brick adhesive products.

Here’s a comparison table for quick reference:

| Adhesive Name | Compatibility | Environment | Curing Method | Special Features |

|---|---|---|---|---|

| Adiseal Weatherproof Adhesive | Brick, Masonry | Extreme Weather | Air Dry | High Durability |

| Loctite PL 500 Landscape Block Adhesive | Brick, Concrete | Outdoor, Humid | Pressure-Sensitive | Heavy-Duty |

| Loctite PL 375 Heavy Duty Adhesive | Brick, Wood | General | Air Dry | Versatile |

Following these tips and using the best practices will help you achieve a strong and lasting bond when working with brick surfaces. For more information on adhesives, explore our articles on can you use super glue for arrow inserts and flexbond vs. versabond.