What Adhesive Sticks to Ceramic Tile: Top Options

Understanding Ceramic Tile Adhesives

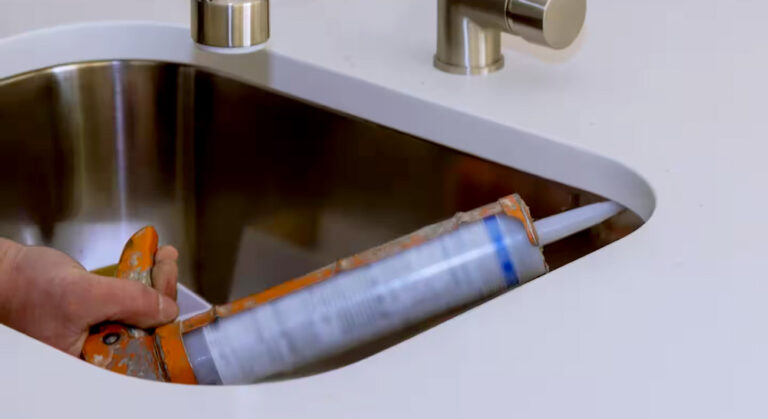

Choosing the right adhesive is essential for a successful ceramic tile installation. Whether you’re working on a flooring project or a wall adornment, understanding the available options and the importance of proper seating can ensure your ceramic tiles stay in place for years to come.

Ceramic Tile Adhesive Options

To achieve optimal results, different adhesives are recommended based on the type of tile and its application. Popular adhesives for ceramic tiles include:

- Custom Building Products AcrylPro: A highly recommended adhesive for its strong bonding capabilities suitable for ceramic tiles.

- ROBERTS Ceramic Tile Adhesive: Known for its ease of use and effective bond for ceramic installations.

- S-515 Adhesive: Recommended for commercial flooring projects, ensuring proper seating and optimal bonding when used with the right techniques (Floor Expert).

- S-1000 Flooring Adhesive: Often used for various tile types, ensuring long-lasting adhesion.

Each adhesive offers different strengths and is suitable for various environments and tile types.

For people wondering what adhesive sticks to ceramic tile, these recommendations can serve as an excellent starting point.

| Adhesive Type | Characteristics | Suitable For |

|---|---|---|

| AcrylPro | Strong bond, easy application | General ceramic tile applications |

| ROBERTS | Ease of use, effective | Residential and small-scale projects |

| S-515 | Professional-grade, optimal seating | Commercial flooring projects |

| S-1000 | Long-lasting adhesion | Various tile applications |

Importance of Proper Seating

Proper seating of ceramic tiles is critical to ensure they remain securely in place. This involves:

- Surface Preparation: Clean and level surfaces are essential. Remove all dust, grease, and residues before applying the adhesive (Quora).

- Applying Adequate Pressure: Using a roller or applying consistent pressure helps ensure the adhesive spreads evenly, creating a strong bond (Floor Expert).

- Choosing the Right Adhesive: Different tiles and substrates require specific adhesives for optimal results.

Proper seating not only provides a stable and secure bond but also ensures the longevity of the installation. For more detailed information about various types of adhesives, readers can explore our guide on how to glue ceramic back together.

Taking the time to understand and correctly apply these principles will greatly enhance the durability and appearance of your ceramic tile projects.

Cleaning Adhesive Residue

Adhesive residue on ceramic tiles can be a real nuisance, especially when handling adhesive applications and removals. Using the correct cleaning techniques is essential to ensure the tiles remain pristine and ready for new adhesive applications.

Cleaning Techniques for Ceramic Tiles

To remove adhesive residue from ceramic tiles effectively, the right cleaning techniques must be used. Adhesive on the surface of ceramic tiles can result from various causes, including spilled adhesive being tracked onto the tile surface or adhesive oozing through tile joints (ForTrendsMag). This residue tends to be sticky, attracts dirt, and appears unsightly.

Here are some recommended steps for cleaning adhesive residue from ceramic tiles:

- Mechanical Removal: Use a plastic scraper to gently lift off any large chunks of adhesive. Avoid using metal scrapers to prevent scratching the tile surface.

- Warm Soapy Water: For initial cleaning, dampen a cloth with warm, soapy water and gently rub the residue. This can often loosen the adhesive.

- Chemical Cleaners: For more persistent residues, use a cleaner specifically designed for removing adhesives. It’s crucial to follow the manufacturer’s instructions to avoid damaging the tiles.

- White Vinegar Solution: A mixture of equal parts white vinegar and water can be a natural alternative to chemical cleaners. Apply the solution to the residue and let it sit for a few minutes before wiping it off.

It’s important to note that adhesives should not be applied over old adhesive residues without proper removal. Proper cleaning prevents bonding issues with new adhesive applications (ForTrendsMag).

Denatured Alcohol Usage

Denatured alcohol is an effective solution for cleaning adhesive residue from ceramic tiles. This solvent works well in breaking down adhesives and ensures a clean surface.

Steps for Using Denatured Alcohol:

- Dampen a clean white cloth with denatured alcohol (Floor Expert).

- Gently rub the cloth over the adhesive residue. The alcohol helps dissolve the adhesive without damaging the tile surface.

- For stubborn residues, let the alcohol sit on the adhesive for a few minutes before rubbing.

- Wipe the area with a damp cloth to remove any remaining alcohol and residue.

- Dry the surface with a clean cloth to ensure no alcohol remains on the tiles.

Denatured alcohol usage is safe for most ceramic tiles and provides an efficient method for removing even the most stubborn adhesive residues. For more tips on tackling tough adhesive cleaning tasks, explore our article on goo gone vs. acetone, which compares popular cleaning agents.

To maintain the longevity and appearance of your ceramic tiles, effective residue removal methods are essential. Always follow the best practices and use appropriate cleaning agents to ensure your tiles remain in top condition. For additional information on adhesive products and their applications, check out our articles on what adhesive sticks to brick and what can i use instead of spray adhesive.

Adhesive for Peel and Stick Tiles

When it comes to peel and stick tiles, it is essential to understand the type of adhesive used and how to ensure a proper application on ceramic tiles. This section will cover pre-applied pressure adhesive and the specific steps for applying peel and stick tiles onto ceramic surfaces.

Pre-applied Pressure Adhesive

Peel and stick tiles come with a backside covered in pre-applied pressure adhesive. This design eliminates the need for additional adhesive, making the installation process straightforward and quick. The adhesive is specifically formulated to provide a strong bond with various surfaces, including ceramic tiles.

Key benefits of pre-applied pressure adhesive include:

- Ease of installation: Simply peel off the backing and press the tile onto the desired surface.

- No mess: Reduces the need for additional adhesive products, which can be messy and time-consuming to apply.

- Strong bond: Provides a secure attachment that can withstand daily wear and tear.

Application on Ceramic Tiles

Applying peel and stick tiles to ceramic tiles involves several crucial steps to ensure a durable and lasting installation:

Surface Preparation

-

Clean the Ceramic Tiles: Ensure the tiles are free of dirt, grime, and grease. Use a suitable cleaner or denatured alcohol to remove any residue.

-

Dry the Surface: Make sure the surface is completely dry before applying the tiles.

-

Smooth Out Imperfections: Repair or smooth out any cracks or uneven areas on the tile surface.

Installing the Tiles

-

Measure and Plan: Measure the area to determine the number of tiles needed. Plan the layout beforehand to avoid cutting tiles mid-application.

-

Peel: Start by peeling off the backing of the peel and stick tile, revealing the adhesive surface.

-

Stick: Press the tile firmly onto the ceramic surface, starting from one corner and working your way across. Apply even pressure to ensure a strong bond.

-

Trim Edges: If necessary, trim the edges of the tiles to fit around obstacles or to create a neat edge.

| Adhesive Type | Recommended Use | Application Time | Cure Time |

|---|---|---|---|

| Pre-applied Pressure Adhesive | Peel and Stick Tiles | Immediate | 24 – 72 hours |

For more detailed advice on various adhesive types for ceramic tiles, you can explore our guide on what adhesive sticks to ceramic tile. If you’re dealing with stubborn adhesive residue, check out the comparison article on citra solv vs. goo gone for effective cleaning solutions. For questions about other glue-related topics, visit goof off vs. wd-40 and other internal links to guides and reviews.

Popular Ceramic Tile Adhesive Brands

When selecting the best adhesive for ceramic tiles, it’s crucial to choose reputable brands known for their quality and reliability. Below are two popular ceramic tile adhesive brands that many professionals and DIY enthusiasts trust.

Custom Building Products AcrylPro

Custom Building Products AcrylPro is a widely recognized adhesive brand, offering various options suitable for ceramic tile installations. It is available in different sizes, including 1 quart, 1 gallon, and 3.5 gallons, catering to projects of varying scales.

Features:

- Sizes: 1 qt., 1 gal., 3.5 gal.

- Drying Time: 72 hours

- Application: Professional tile installation

- Key Benefit: Long-lasting bond and easy to apply

Custom Building Products AcrylPro adhesive is known for its professional-grade quality, ensuring a strong and durable bond for ceramic tiles. Its extended drying time allows for precise adjustments and alignment during installation, making it a top choice for meticulous projects.

| Product | Sizes Available | Drying Time | Key Benefit |

|---|---|---|---|

| Custom Building Products AcrylPro | 1 qt., 1 gal., 3.5 gal. | 72 hours | Long-lasting bond, Easy application |

For more details on adhesives that can be used for different projects, consider reading articles on how to glue ceramic back together and how to install wall panels with adhesive.

ROBERTS Ceramic Tile Adhesive

ROBERTS is another trusted brand offering specialized products for ceramic tile applications. Their adhesive range includes the IA1O 1 gal. Interior Stone Veneer Adhesive and the ROBERTS 3.5 Gal. Ceramic Tile Adhesive.

Features:

- Sizes: 1 gal., 3.5 gal.

- Application: Ceramic tile installations

- Key Benefit: Strong adhesion, Ideal for various surfaces

ROBERTS ceramic tile adhesive is designed for robust bonding, making it suitable for different surfaces, providing versatility in tile applications.

| Product | Sizes Available | Application | Key Benefit |

|---|---|---|---|

| ROBERTS IA1O 1 gal. Interior Stone Veneer Adhesive | 1 gal. | Ceramic tile installations | Strong adhesion |

| ROBERTS 3.5 Gal. Ceramic Tile Adhesive | 3.5 gal. | Ceramic tile installations | Versatile usage |

ROBERTS adhesives are reliable and offer excellent performance, making them a preferred choice for both professionals and DIY enthusiasts. To explore alternative uses of adhesives, you can read about can you use super glue for arrow inserts and learn how to glue arrow inserts.

Both Custom Building Products AcrylPro and ROBERTS provide dependable solutions for ceramic tile installations, ensuring a strong and durable bond.

Factors Influencing Adhesive Selection

When selecting an adhesive for ceramic tiles, several factors must be considered to ensure optimal performance and longevity. These factors include the type of tile being used and the importance of thorough surface preparation.

Tile Type Considerations

Different types of ceramic tiles have unique properties that influence the choice of adhesive. Two common types are porcelain and glazed porcelain tiles.

-

Porcelain Tiles: These are a stronger variant of ceramic, with a water absorption rate of less than 0.5%. This makes them exceptionally hard and suitable for areas with heavy foot traffic (Olde English Tiles). When selecting an adhesive for porcelain tiles, it’s crucial to choose one that can handle the density and weight of the tiles.

-

Glazed Porcelain Tiles: These tiles feature a glaze that acts as a sealant. They are classified based on their abrasion resistance, indicating their suitability for various traffic levels from light to intense, such as in shopping malls and airports. Adhesive selection for glazed porcelain tiles should consider the tile’s exposed surface and required bonding strength.

Table: Adhesive Suitability Based on Tile Type

| Tile Type | Recommended Adhesive |

|---|---|

| Porcelain | High-strength, flexible adhesive |

| Glazed Porcelain | Medium-strength adhesive |

Selecting the right adhesive based on tile type is essential for ensuring the tiles remain securely in place and are resistant to wear and tear.

Surface Preparation Importance

Proper surface preparation is vital for the success of any tiling project. Before applying a new adhesive, it is critical to thoroughly remove any old adhesive, as applying new adhesive over old trowel notches can lead to poor bonding.

Key Considerations:

- Adhesive Removal: Adhesives can be removed mechanically or chemically. However, if chemical removers are used, any residue must be cleaned up thoroughly to avoid issues with the new adhesive.

- Curing Conditions: Adhesives should ideally cure between 60°F and 70°F to ensure proper chemical bonding. This temperature range reduces moisture evaporation, preventing shrinkage and ensuring the adhesive develops its full properties under stress. Inadequate curing conditions can account for about 34% of construction project issues (Dukoll).

Table: Curing and Application Conditions

| Aspect | Ideal Conditions |

|---|---|

| Temperature Range | 60°F – 70°F |

| Adhesive Removal | Thorough mechanical/chemical |

| Chemical Residue Cleanup | Thorough post-removal cleanup |

Understanding and implementing proper surface preparation techniques is crucial for ensuring that the adhesive bonds effectively with the ceramic tiles.

To learn more about specific adhesives and their applications, visit our guide on what adhesive sticks to ceramic tile. For additional adhesive-related inquiries, explore our articles on how to glue ceramic back together and gutter sealant vs. silicone.

Specialized Tile Adhesive Types

Selecting the correct adhesive for ceramic tile installation can be a daunting task given the variety of options available. Understanding the different types of adhesives can help ensure a strong and lasting bond. Here, we will delve into cementitious adhesives, dispersion adhesives, fast-setting adhesives, and deformable adhesives.

Cementitious and Dispersion Adhesives

Cementitious adhesives are commonly used for tile installations. Made primarily from cement, these adhesives provide a robust bond for ceramic tiles, offering durability and moisture resistance.

| Type | Characteristics | Best For |

|---|---|---|

| Cementitious Adhesive | High strength, water-resistant | Bathroom and kitchen tiles |

| Dispersion Adhesive (D1) | Normal adhesive, polymer dispersion | Wood, paper, fabric |

| Dispersion Adhesive (D2) | Improved adhesive, enhanced bonding | High-traffic areas |

Dispersion adhesives, also known as polymer adhesives, are categorized as either normal (D1) or improved (D2). These adhesives are versatile and are suitable for bonding various materials, including wood, paper, and fabric.

Fast-setting and Deformable Options

Fast-setting adhesives are ideal for projects that require expedited completion. These adhesives, indicated by the class F, dry or set quickly, allowing for faster turnaround times.

| Type | Characteristics | Best For |

|---|---|---|

| Fast-setting Adhesive (F) | Quick drying, reduced waiting time | Speedy project completion |

| Deformable Adhesive (S1) | Flexibility, withstands movements | Areas with slight surface movements |

| Highly Deformable Adhesive (S2) | High flexibility, accommodates significant movements | Dynamic environments |

Deformable adhesives, classified as S1 for deformable and S2 for highly deformable, are specialized in their ability to flex and accommodate slight movements or changes in the surfaces they are applied to. This makes them particularly suitable for environments where the substrate may experience shifts or expansions (Weber).

When selecting an adhesive for ceramic tiles, proper consideration of factors such as tile type, surface preparation, and expected conditions is essential. For more insight on these aspects, visit our section on tile type considerations and surface preparation importance. For alternative adhesive options, check out what adhesive sticks to silicone and what adhesive sticks to brick.

By understanding the attributes and best applications for each type of tile adhesive, you can make an informed decision that ensures the durability and stability of your ceramic tile installation.